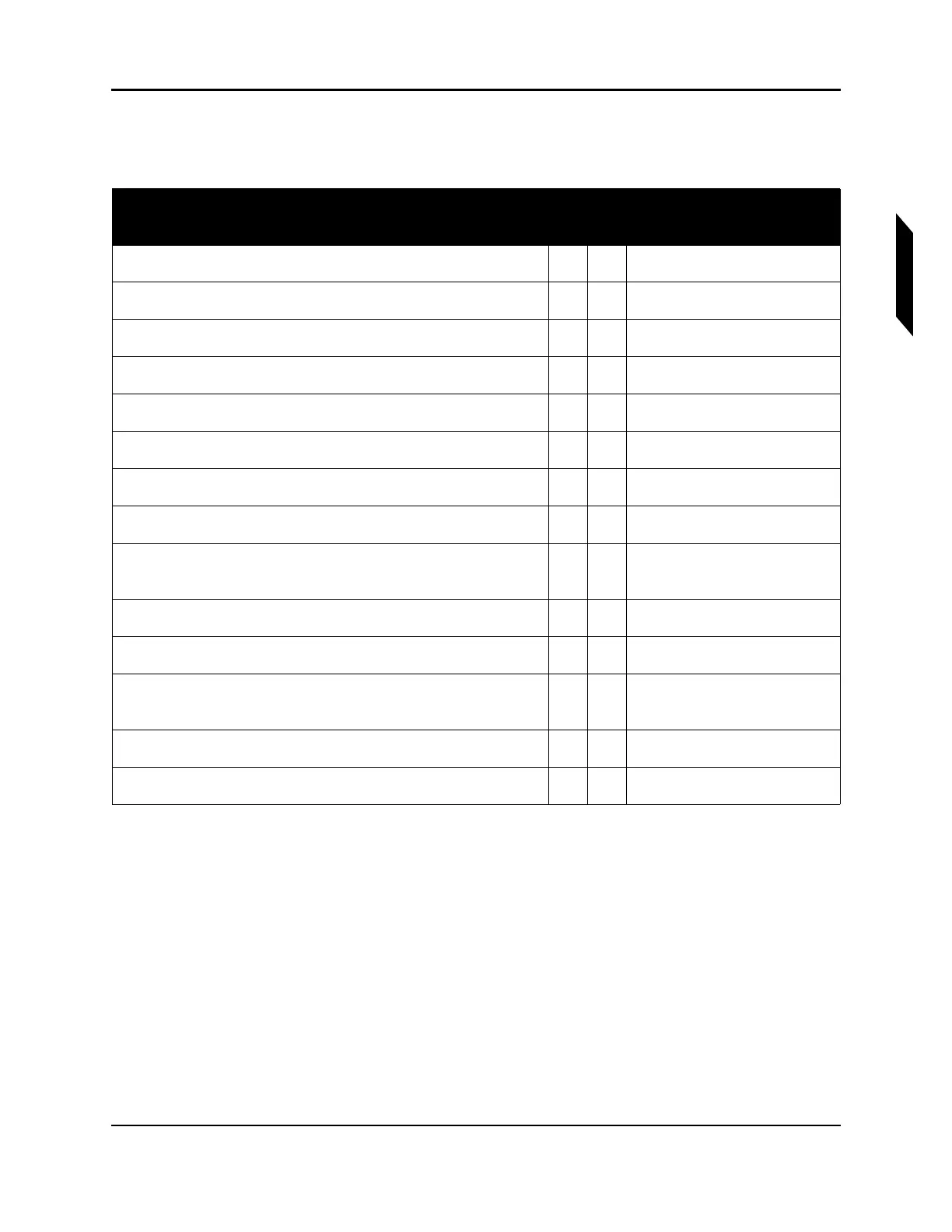

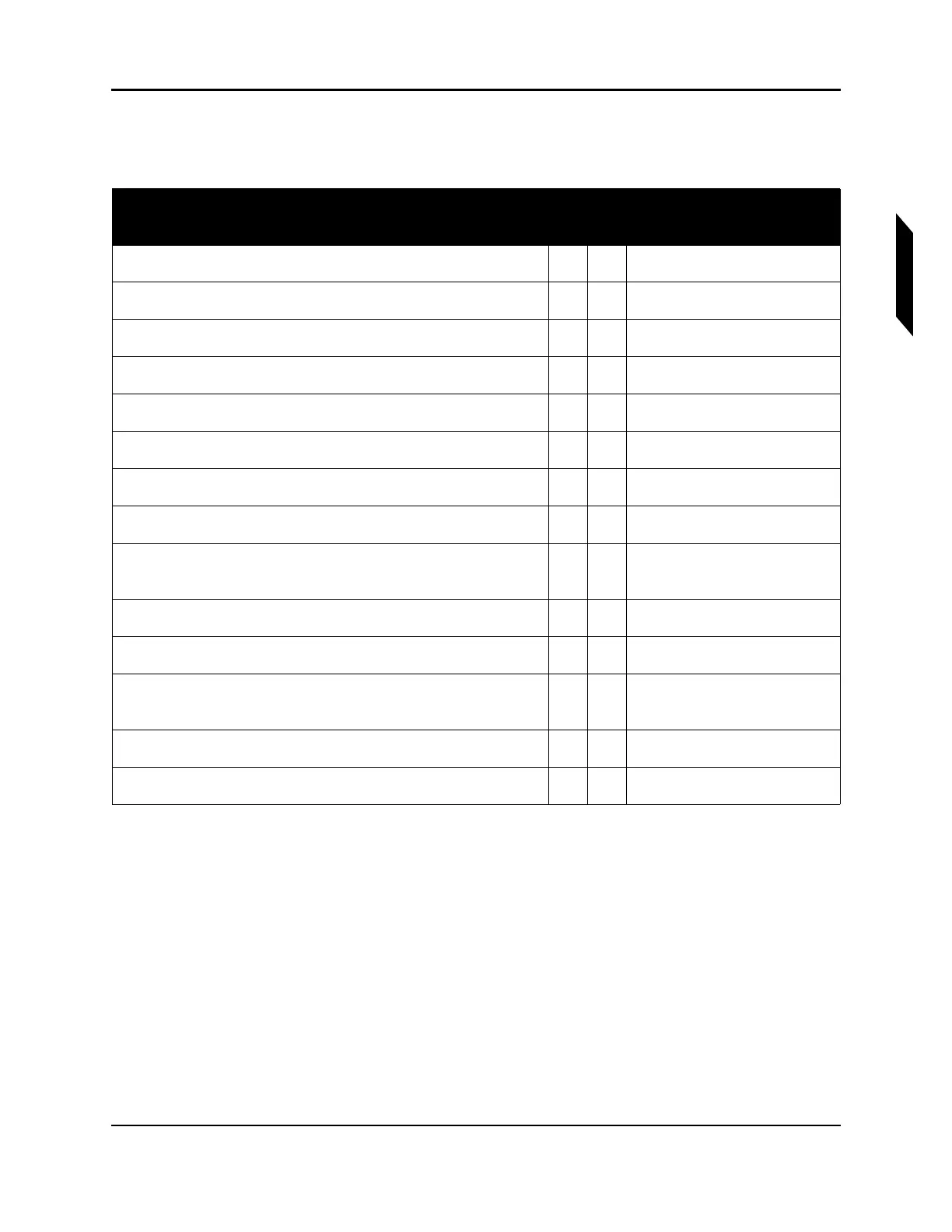

INSPECTIONS / CONDITION INSPECTIONS AND 100-HOUR INSPECTIONS 3-25

CHANGE C2 ICON A5 / MAINTENANCE MANUAL

3.3.10 Condition and 100-Hour Inspection—Operational Inspection

RELATED INFORMATION:

"Annunciator Panel Function" on page 13-38

"Oil Cooler and Radiator Condition Inspection" on page 16-55

"Approved Fuel Grades and Specifications" on page 2-28

"Inspect Engine Mount" on page 16-30

"Removal and Installation of Inspection Panels and Fairings" on page 3-34

"Basic Electrical System Inspection" on page 6-31

Correct all unsatisfactory items prior to flight

S=Satisfactory, U=Unsatisfactory

S U Comments

Perform toolbox inventory check (no tools left in aircraft)

Visual inspection of the engine/propeller

All inspection panels and fairings secure

Personnel with fire bottles standing by

Brake system check

Proper fuel in tank

Engine start procedures

Perform engine runup per POH

Static full-power rpm check (See “Engine Test Run” on

page 16-7.)

Electrical system check

Check annunciator panel function

Cool down period/engine shut down (See “Engine Test

Run” on page 16-7.)

Perform oil, hydraulic, and fuel leak check

Check overhead console fuses

Loading...

Loading...