2-24 Service Manual

5026

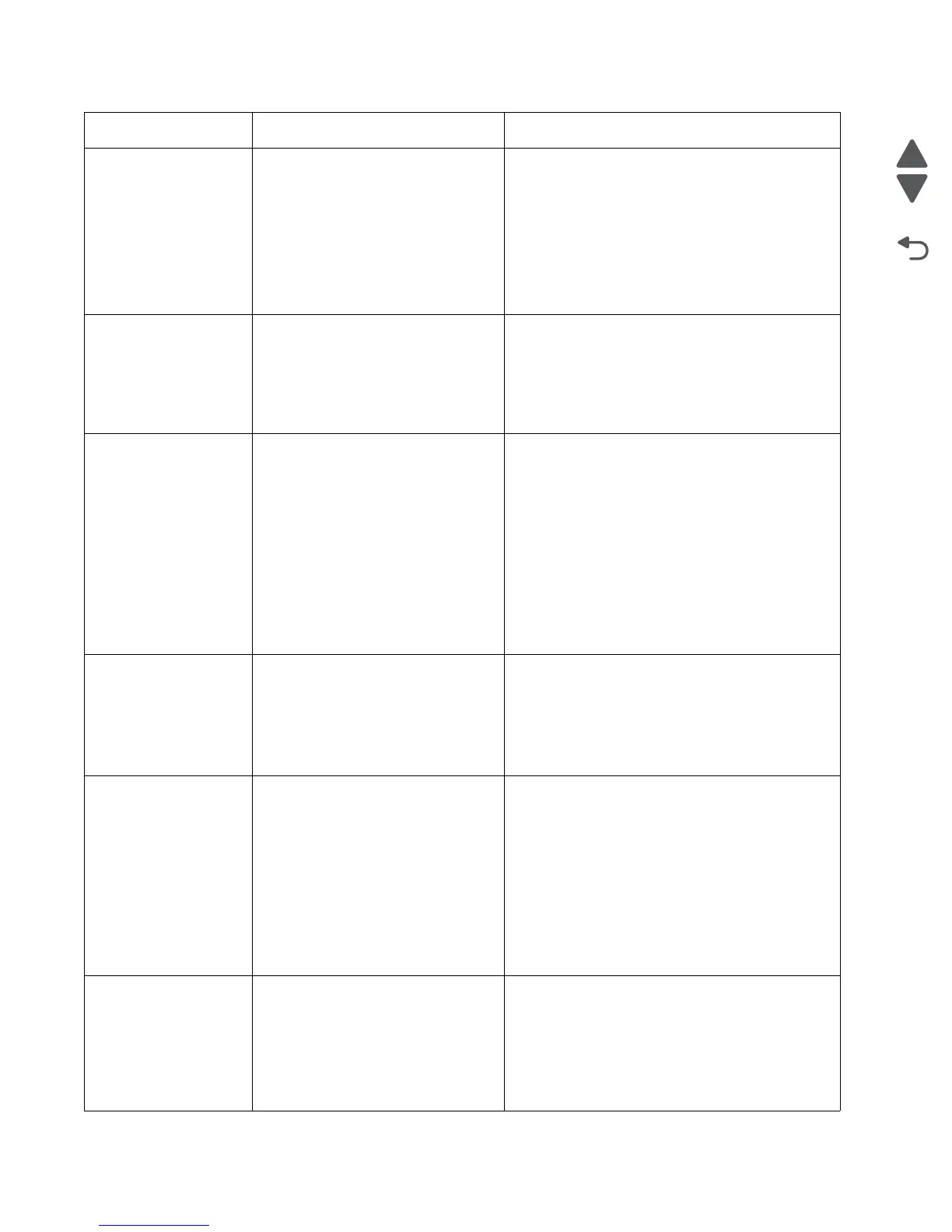

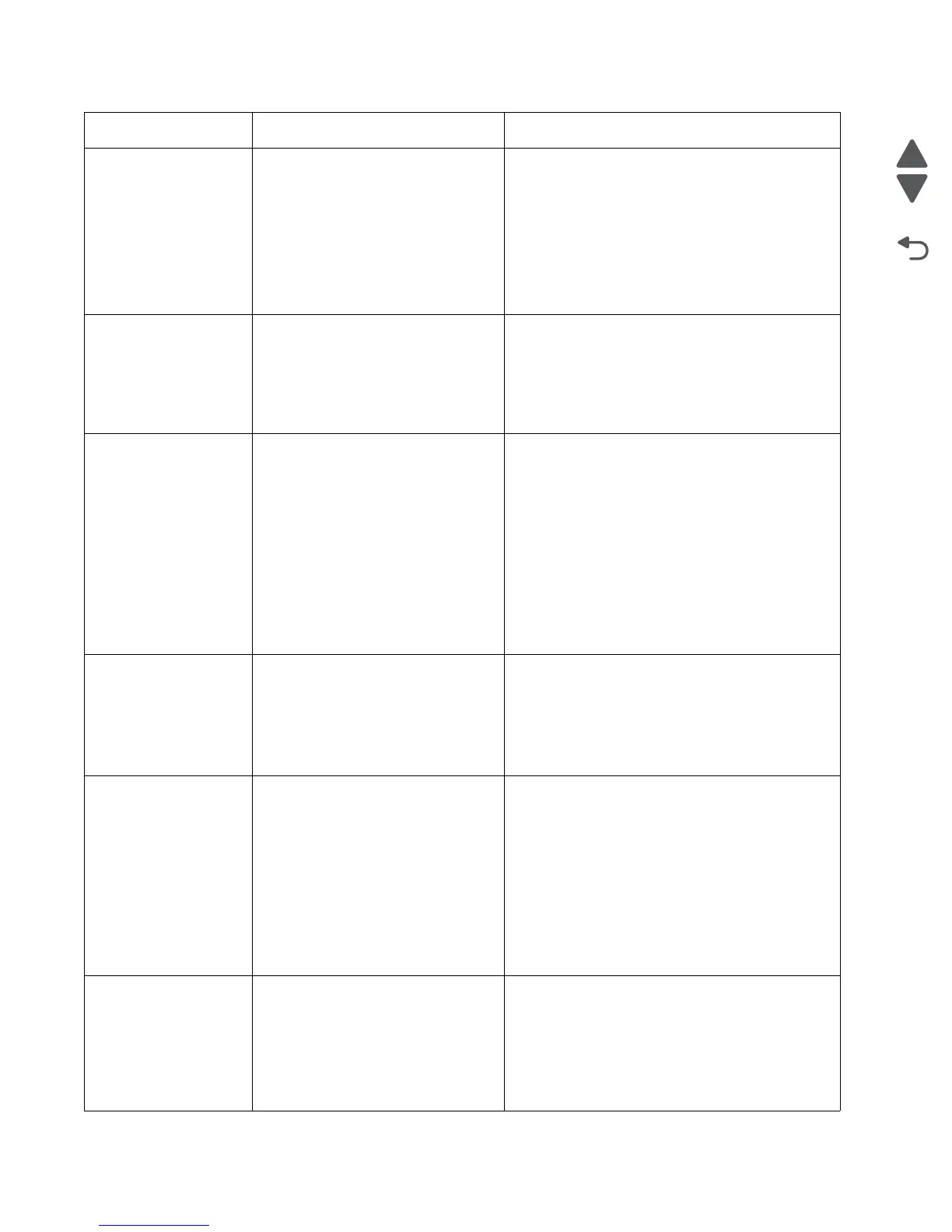

242.05 Tray 2 picked, but page failed to reach

the option sensor in time.

Possible causes:

• Incorrect media setting

• Incorrect paper loading

• Incorrect media restraint setting

• Loading card stock from the

special media tray above the fill

line.

1. Ensure proper media is set for the type of paper

used in tray 2.

2. Fan media, and stack flat in tray 2.

3. Properly set the media restraints in tray 2.

4. Check the pick arm rolls (tires) in tray 2 and

replace if worn.

If the previous actions do not fix the problem, go to

“242.05—Paper Jam service check” on

page 2-70.

242.10 Tray 2 page exits pass thru made

early.

Possible causes:

• Defective pass thru sensor

• Faulty cable in the connector

JOPT1 on system board.

• Ensure the proper media is set for the type of

paper used in tray 2.

• Check for anything in the paper path that might

cause the paper to jam.

• The exits pass thru sensor may not be

functioning properly. Go to “242.10—Paper

Jam service check” on page 2-71.

242.11 Tray 2 sensor never broke.

Possible causes:

• Incorrect tray 2 media setting

• Incorrect Tray 2 paper loading

• Incorrect media restraint setting

• Paper tray 2 failure

• Aligner failure

• Transport belt module failure

• Loading card stock from the

special media tray above the fill

line.

• High humidity (replace paper)

1. Ensure the proper media is set for the type of

paper used in tray 2.

2. Fan media, and then stack flat in tray 2.

3. Properly set the media restraints in tray 2.

Go to “242.03, 242.11—Paper Jam service

check” on page 2-69.

242.17 Tray 2 detected a jam from idle.

Possible causes:

• Paper jam leaving page over

sensor

• Defective input sensor

• Faulty system board

• Clear away anything in the paper path that might

cause the paper to jam.

• If clearing a paper jam does not fix the problem,

“242.17—Paper Jam service check” on

page 2-72.

242.26 While feeding from tray 2, the pass

thru sensor is not made.

Possible causes:

• Incorrect paper loading for lower

tray

• Incorrect media restraint setting

for lower tray

• Paper tray 2 assembly failure

• Lower tray 3 assembly failure

1. Clear away anything in the paper path that might

cause the paper to jam.

2. Ensure the proper media is set for the type of

paper used in the lower tray.

3. Fan the media, and then stack flat in the lower

tray.

4. Properly set the media restraints in the lower

tray.

5. Check the pick arm rolls (tires) in the lower tray,

and then replace if worn.

If the problem persists, go to “242.26—Paper Jam

service check” on page 2-73.

242.27 While feeding from a lower tray, pass

thru sensor did not break.

Possible causes:

• Paper tray 2 assembly failure

(feed through roller)

• Aligner failure

• Transport belt motor failure

• Clear away anything in the paper path that might

cause the paper to jam.

• Reseat option tray 2.

•Go to “242.27—Paper Jam service check” on

page 2-73.

Error code Description Action

Loading...

Loading...