BRAVO THREE GEAR HOUSING

SERVICE MANUAL NUMBER 28

90-863160 MAY 2000 Page 3D-19

Installation

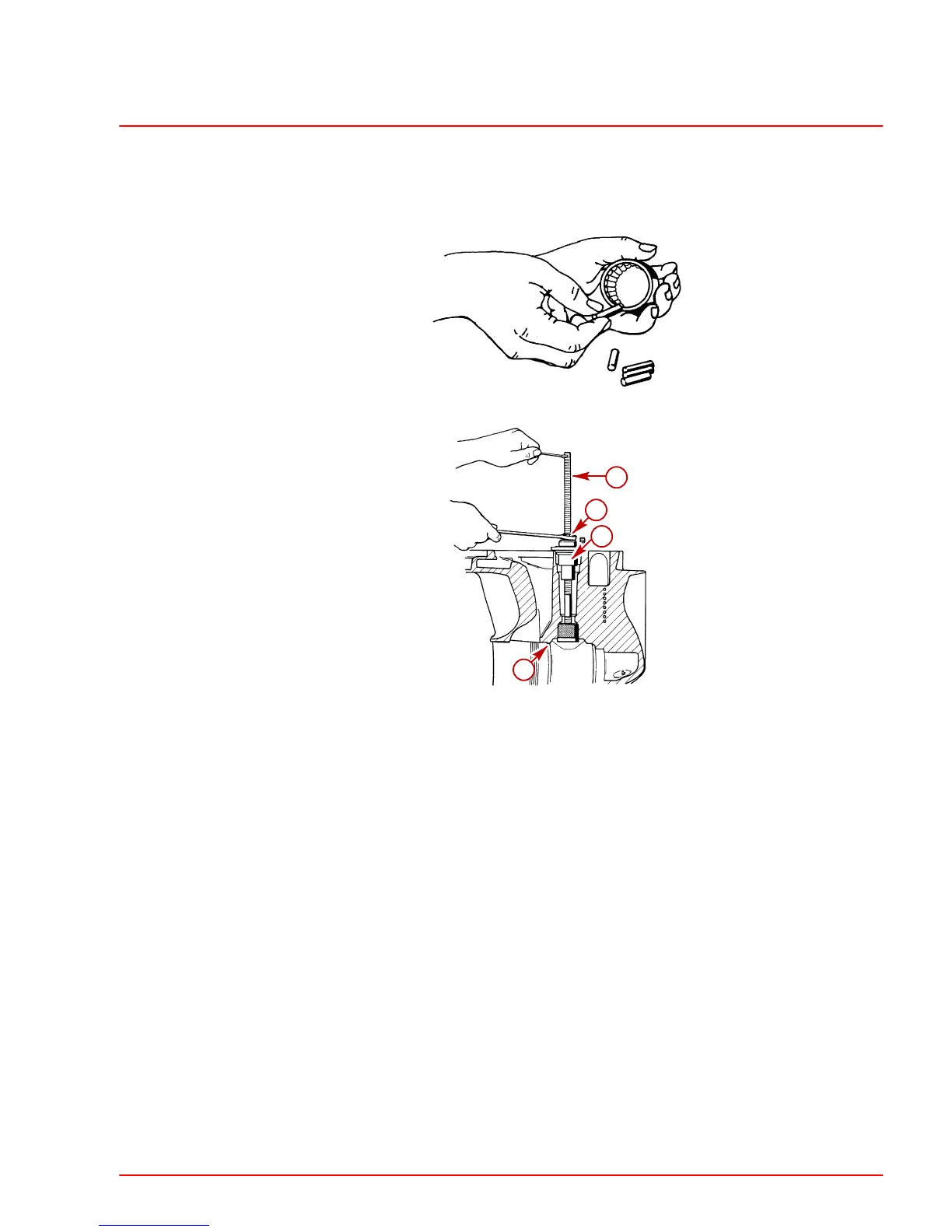

1. Install needles in casing. Use Needle Bearing Assembly Lubricant to help keep needles

in place. Position bearing assembly over bearing driver with number on bearing casing

facing up. Coat casing outer diameter with Quicksilver High Performance Gear Lube.

72443

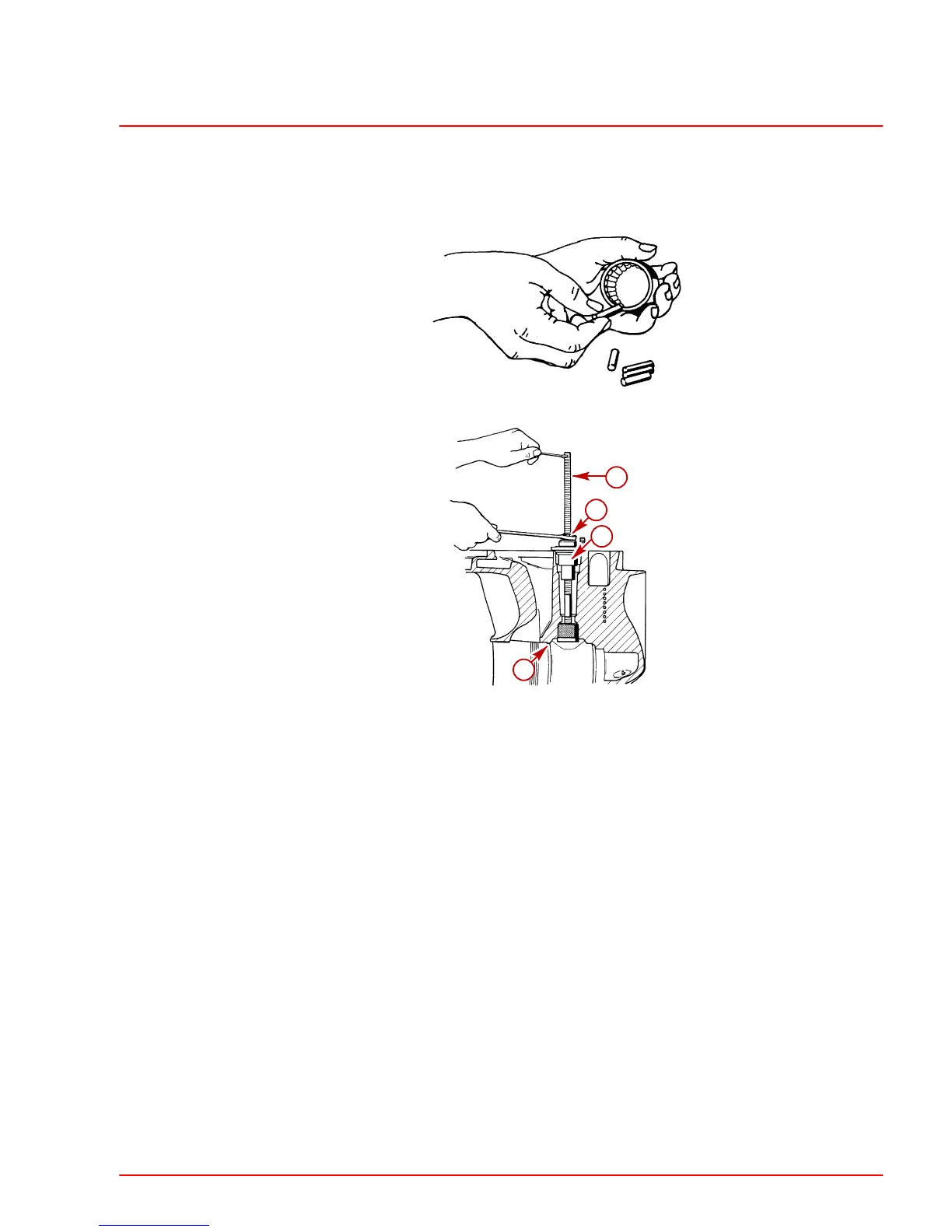

2. Install pinion bearing using tools as shown.

72254

d

a

c

b

a-Bearing Driver (P/N 91-813653) - Used As Pilot

b-Threaded Rod (P/N 91-31229)

c-Washer And Nut

d-Bearing Driver (P/N 91-89867T)

Propeller Shaft

Inspection

1. Inspect for bent or twisted splines.

2. Inspect surface of shaft where bearing carrier oil seal lips contact shaft. Replace shaft

and oil seals if any grooves are found.

3. Inspect needle bearing race on outer propeller shaft and bearing surface of inner propel-

ler shaft for pitting, grooves, discoloration or embedded particles. If any of these condi-

tions exist, replace shaft.

4. Condition of the bearing surfaces on the outer propeller shaft and inner propeller shaft

is an indication of the condition of the bearings in the bearing carrier and outer propeller

shaft. Inspect bearing rollers for pitting, grooves, discoloration or embedded particles.

If any of these conditions exist, replace bearings and shaft.

5. Inspect outer propeller shaft tapered bearing and bearing cup. Replace bearing and

bearing cup if cup is pitted, grooved, scored, worn uneven, discolored from overheating,

or has embedded metal particles.

Loading...

Loading...