TROUBLESHOOTING

SERVICE MANUAL NUMBER 28

90-863160 MAY 2000 Page 1C-29

Corrosion Protection

NOTE:Refer to “MerCathode Controller Wiring Diagram.”

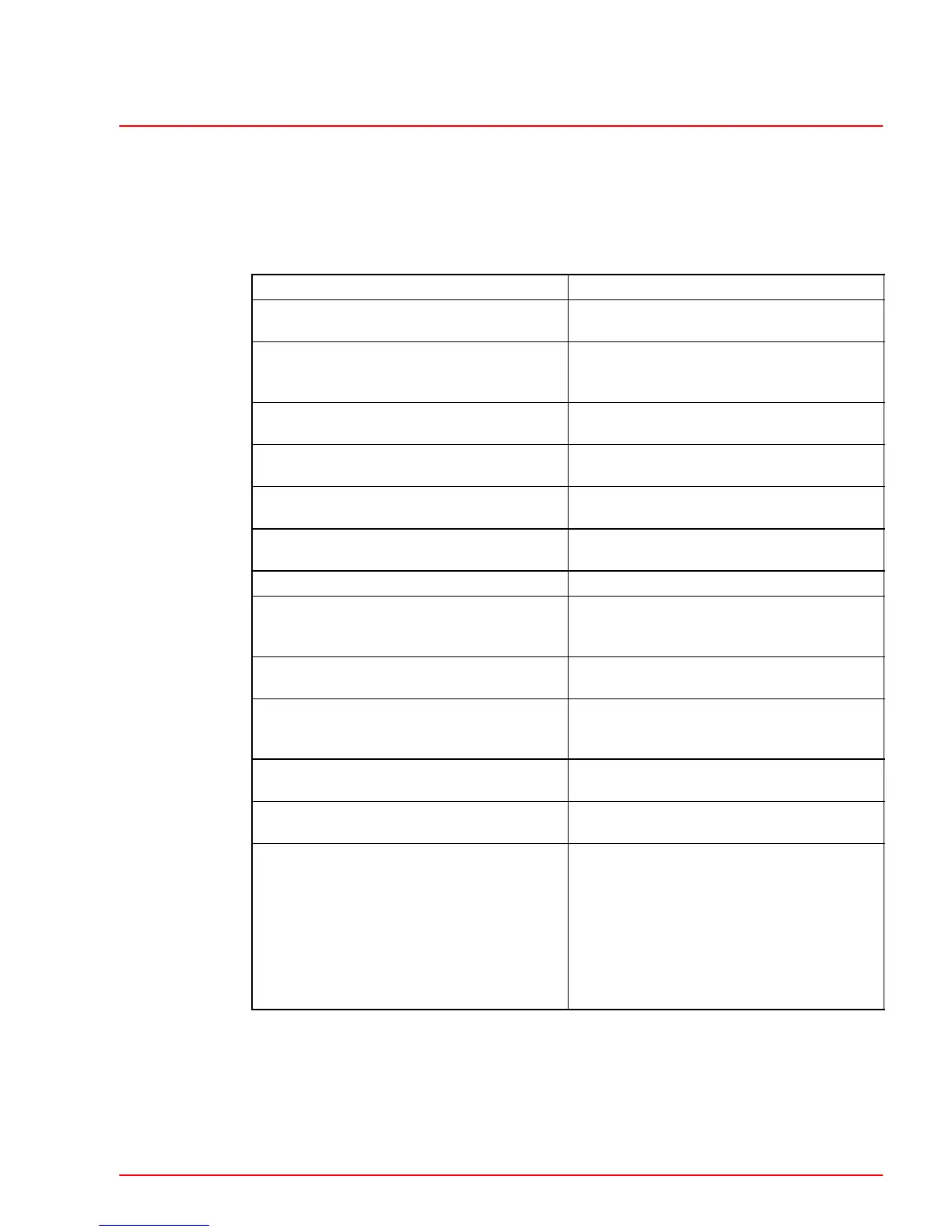

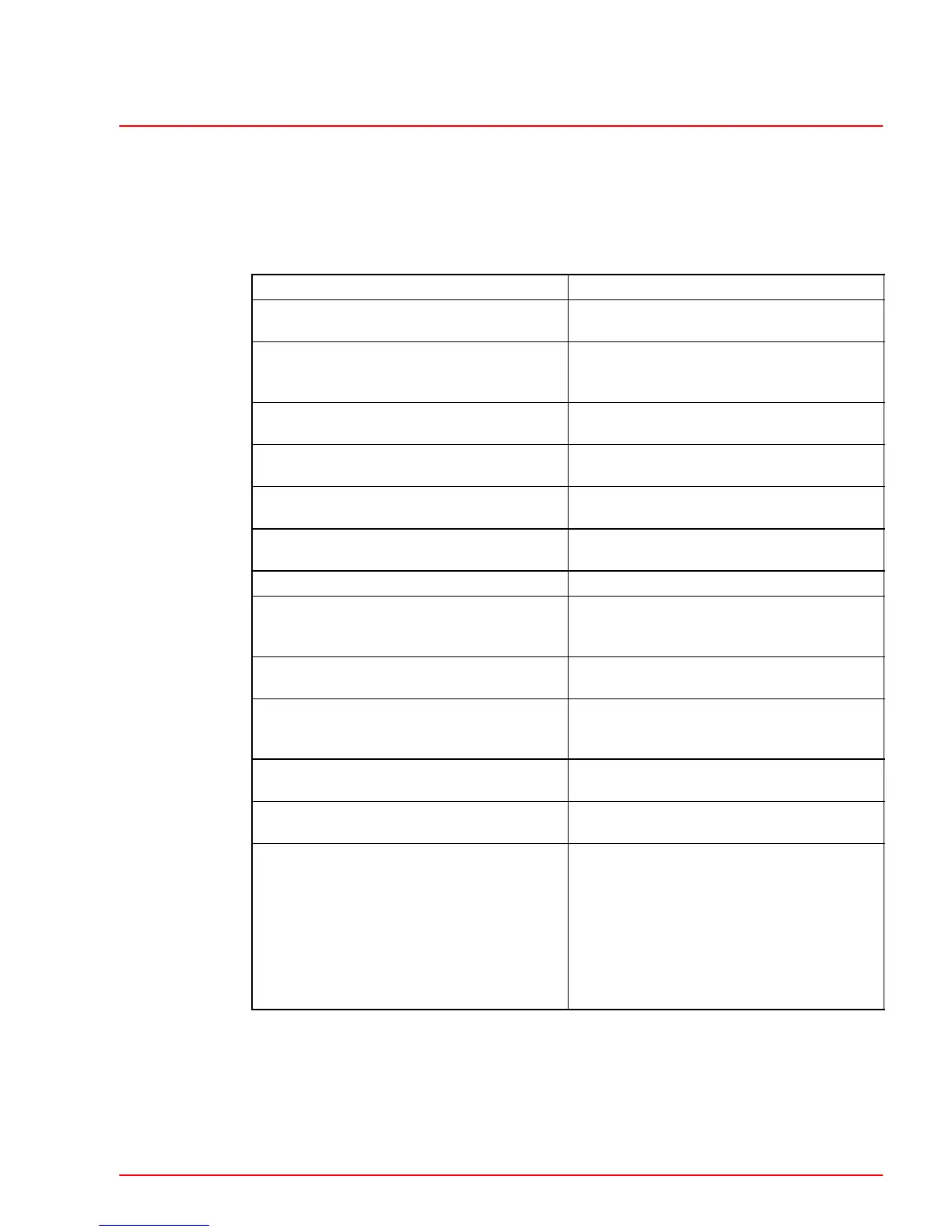

Corrosion On Underwater Parts, Without MerCathode Or Impressed Current

Protection

Cause Special Instructions

Sacrificial anode(s) consumed.

Replace anode(s) when 50%

consumed.

Stainless steel propeller installed.

Add MerCathode (impressed current

protection) or additional sacrificial

anodes.

Sacrificial anode(s) not grounded to

drive.

Remove anode(s), clean contact

surface, reinstall and check continuity.

Loss of continuity between underwater

parts & ground.

Provide good ground connections.

Shore power causing overload of

anode(s) and/or MerCathode.

Disconnect shore power or install

Quicksilver isolator.

Paint on drive heavily worn

(exposing more metal).

Prime and repaint and/or install

additional anode(s).

Sacrificial anode(s) painted. Remove paint or replace anode(s).

Drive tilted so far that anode(s) are out

of the water.

Leave drive down, install additional

anode (below waterline) or transom

mount a MerCathode.

Only power trim cylinders are corroded.

Provide good ground to drive. All parts

must be grounded.

Corrosion in area of exhaust outlets.

Exhaust deposits can cause

corrosion.

Remove deposits with marine or auto

wax.

Corrosion occurring after unit removed

from saltwater.

Wash exterior and flush interior with

fresh water.

Corrosion and/or salt build up between

mating parts.

Exclude moisture from between mating

parts with Quicksilver 2-4-C with Teflon.

Stainless Steel parts corroding:

Tightly wrapped fishing line or foreign

material excludes oxygen, causing

corrosion.

Iron particles, such as from a wire brush,

cause rusting.

Propeller pitting can occur if electrical

continuity is lost.

Clean parts, remove foreign material,

ensure continuity.

Loading...

Loading...