TROUBLESHOOTING

SERVICE MANUAL NUMBER 28

90-863160 MAY 2000 Page 1C-17

Power Trim Hydraulic System

NOTE:Refer to “Power Trim Hydraulic Schematic.”

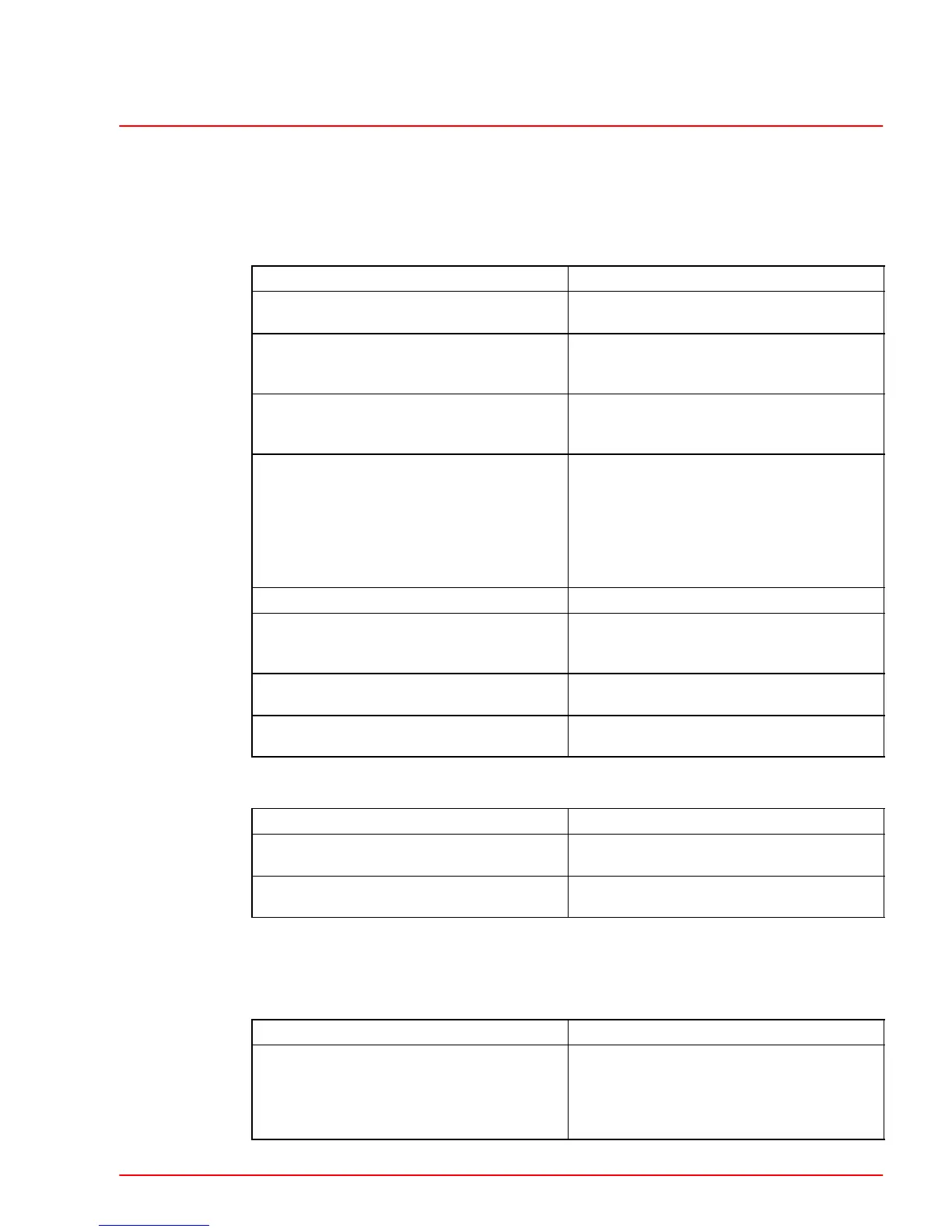

Drive Unit Cannot Be Trimmed OUT/UP Or Trims Slowly Or With Jerky

Movements

Cause Special Instructions

Power trim pump oil level low.

Check for cause of low oil level and

correct. Add oil and bleed trim system.

Air in trim system.

Check for cause of entry and correct.

Add oil to pump and bleed air from

system.

O-rings damaged on Manual Release

Valve (if equipped) or valve not

completely closed.

Replace valve and/or close completely.

Insufficient pump pressure or pump.

shuttle valve stuck.

Test. If shuttle 1 is stuck, replace

pump adaptor (Refer to SECTION 5A). If

pressure is low, replace adaptor or

attempt to repair by replacing the

following components:

D OUT/UP Pressure Relief Valve

D Thermal Relief Valve

Hoses reversed on one cylinder only. Connect hoses 7 and 8 correctly.

Trim cylinder(s) binding.

Check for cause of binding (bent

piston rod, scored cylinder).

Repair or replace as necessary.

Gimbal housing-to-trim pump hydraulic

hose pinched.

Replace hose 7.

Up pressure relief valve has dirt

particles under check ball.

Replace with a new valve kit.

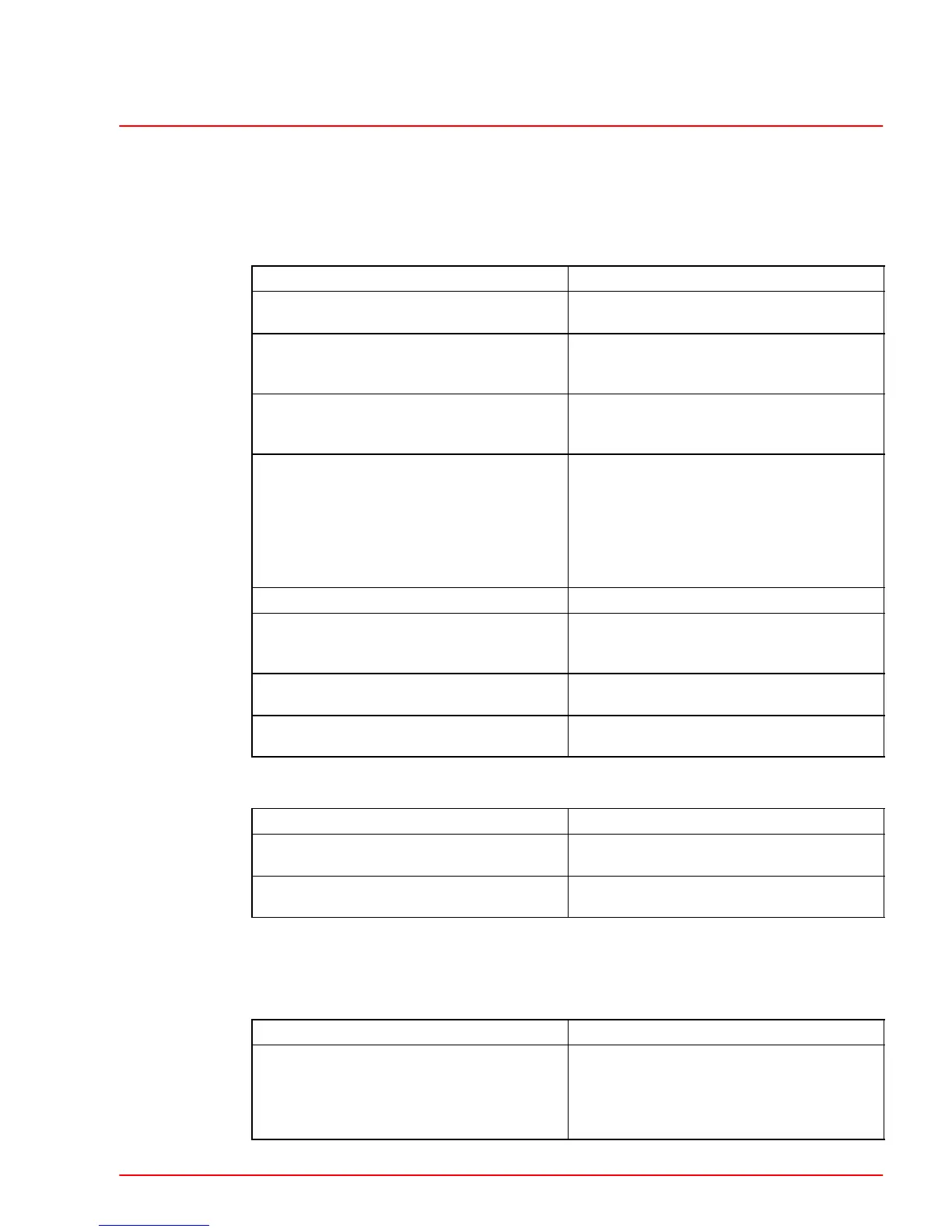

Drive Unit Will Not Stay In Trimmed OUT/UP Position

Cause Special Instructions

Air in trim system.

Check for cause of entry. Fill and bleed

system.

Shuttle valve (poppet valve).

Check for dirt. Install new poppet

valve.

Sterndrive Unit Trails OUT/UP On Deceleration Or When Shifting Into Reverse

UNIT THUMPS WHEN SHIFTING

Cause Special Instructions

Trim pump IN/DOWN circuit leaking

internally.

Test according to appropriate service

manual. Replace adaptor or attempt to

repair by replacing the pilot check

valves or seals. (Install Trim Pump

Rebuild Kit)

Loading...

Loading...