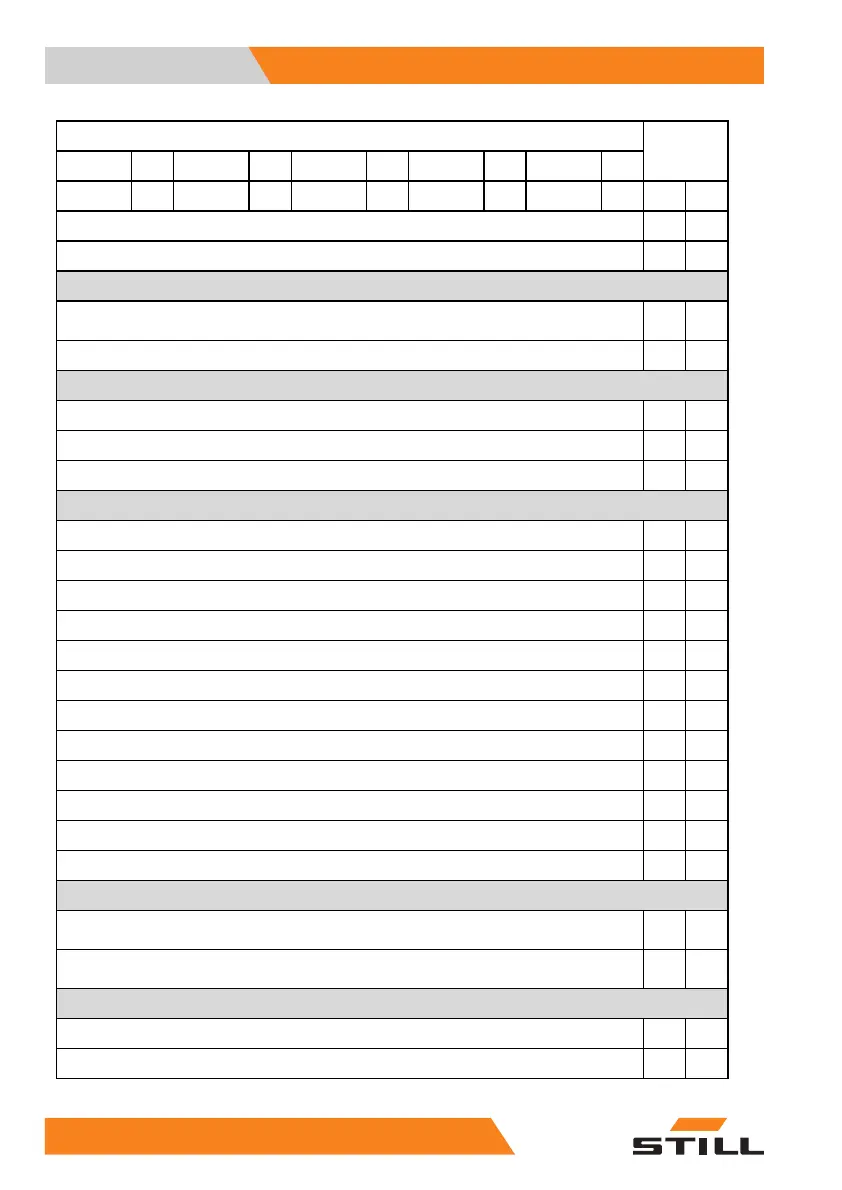

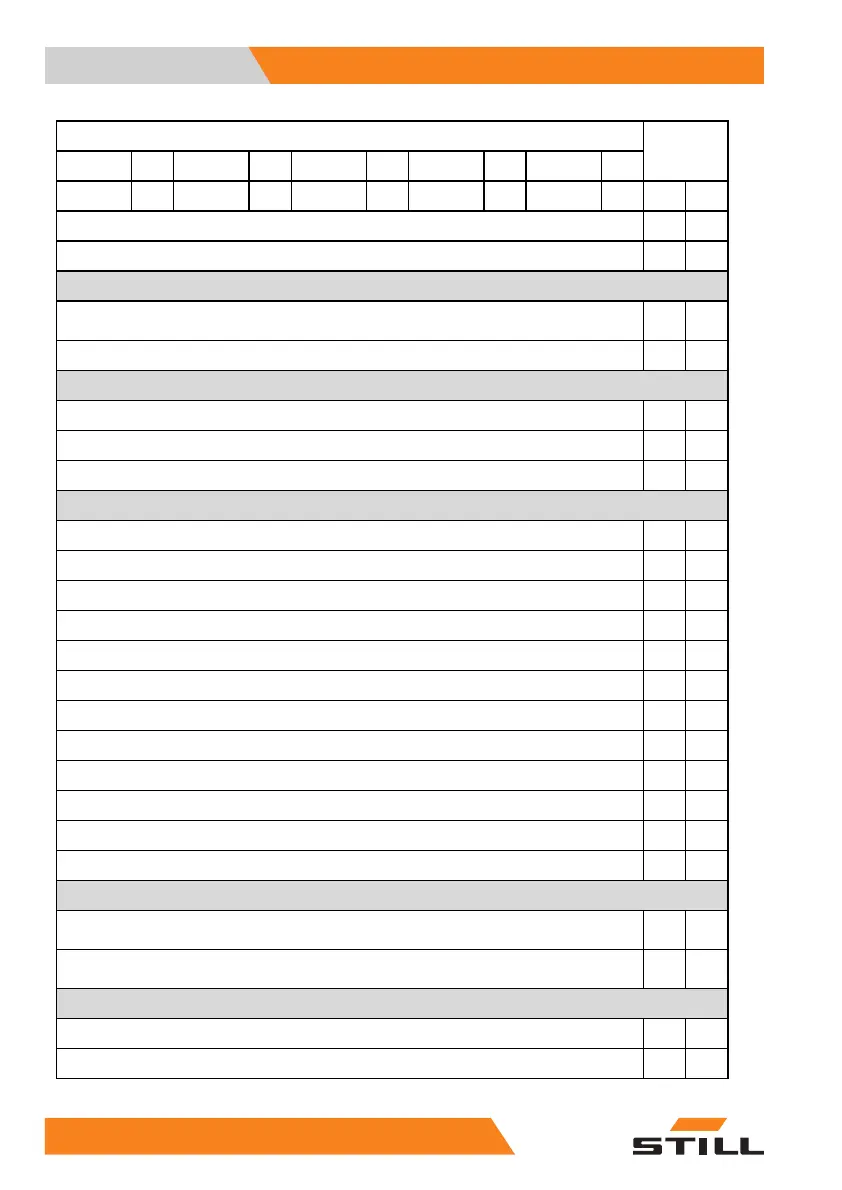

6 Maintenance

General maintenance information

At operating hours

1000 2000 4000 5000 7000

Carried

out

8000 10000 11000 13000 14000

Check the switches, transmitters and sensors for correct function

Check the lighting and indicator lights

Battery and accessories

Check battery for damage and acid density; observe manufacturer’s maintenance

instructions

Check battery male connector and cable for damage

Hydraulics

Check the hydraulic system for condition, correct function and leaks

Check the hydraulics blocking function (ISO valve)

Check the oil level

Lift mast

Check the mast bearings for damage and lubricate. Check the tightening torque

Check the mast profiles for damage and wear, and lubricate

Check the load chains for damage and wear, adjust and lubricate

Check the lift cylinder and connections for damage and leaks

Check the guide pulleys for damage and wear

Check the support rollers and chain rollers for damage and wear

Check the play between the fork carriage stop and the run-out barrier

Check the tilt cylinder and connections for damage and leaks

Check the fork carriage for damage and wear

Check the fork arm interlock for damage and correct function

Check the fork arms for wear and deformation

Check that there is a safety screw on the fork carriage or on the attachment

Special

equipment

Check the attachments for wear and damage; observe the manufacturer’s mainten-

ance instructions

Check the trailer coupling for wear and damage; observe the manufacturer’smai-

ntenance instructions

General

Read out error numbers and delete list

Reset the maintenance interval

29

8 55048011501 EN - 12/2015

Loading...

Loading...