Theory 7

Agilent Nano Indenter G200 User’s Guide 7-16

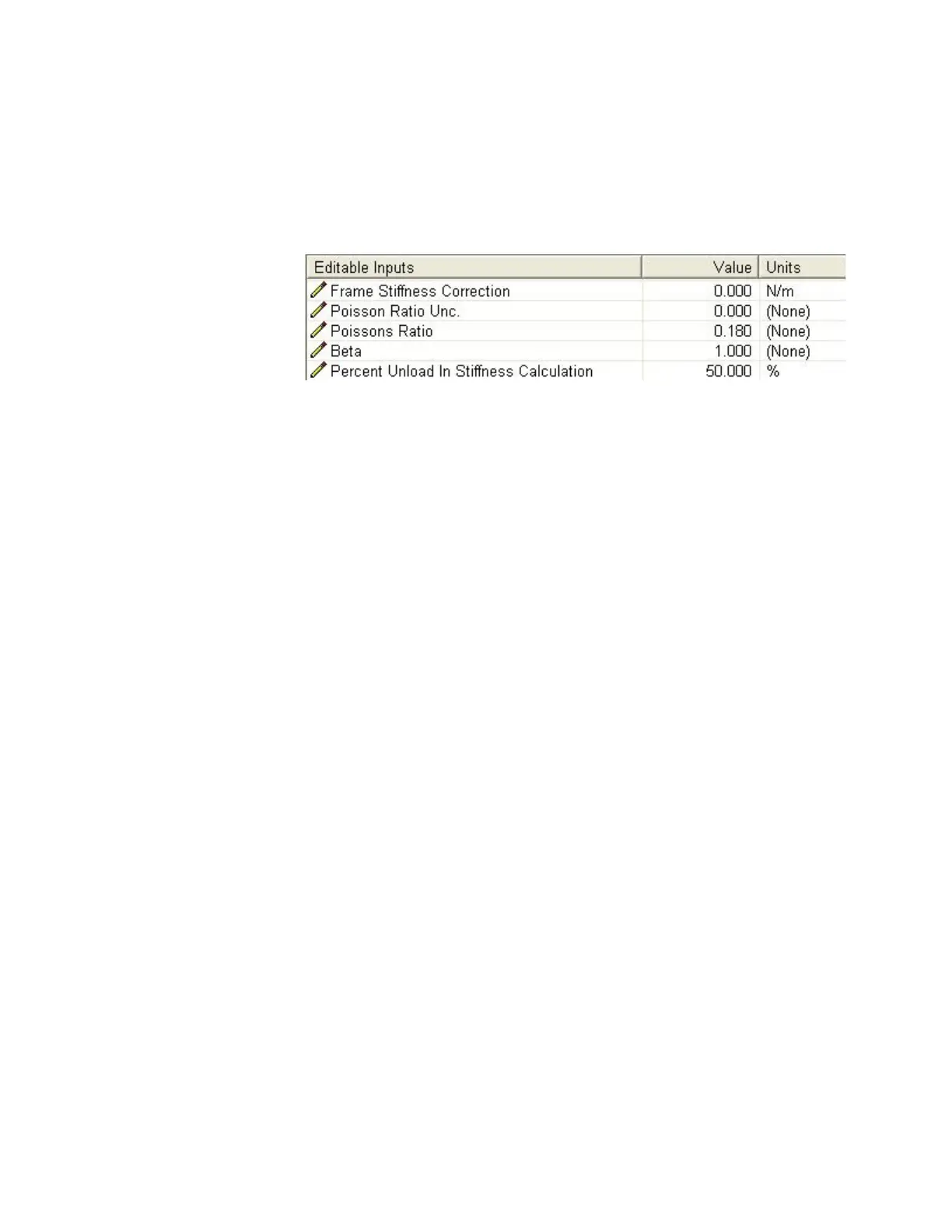

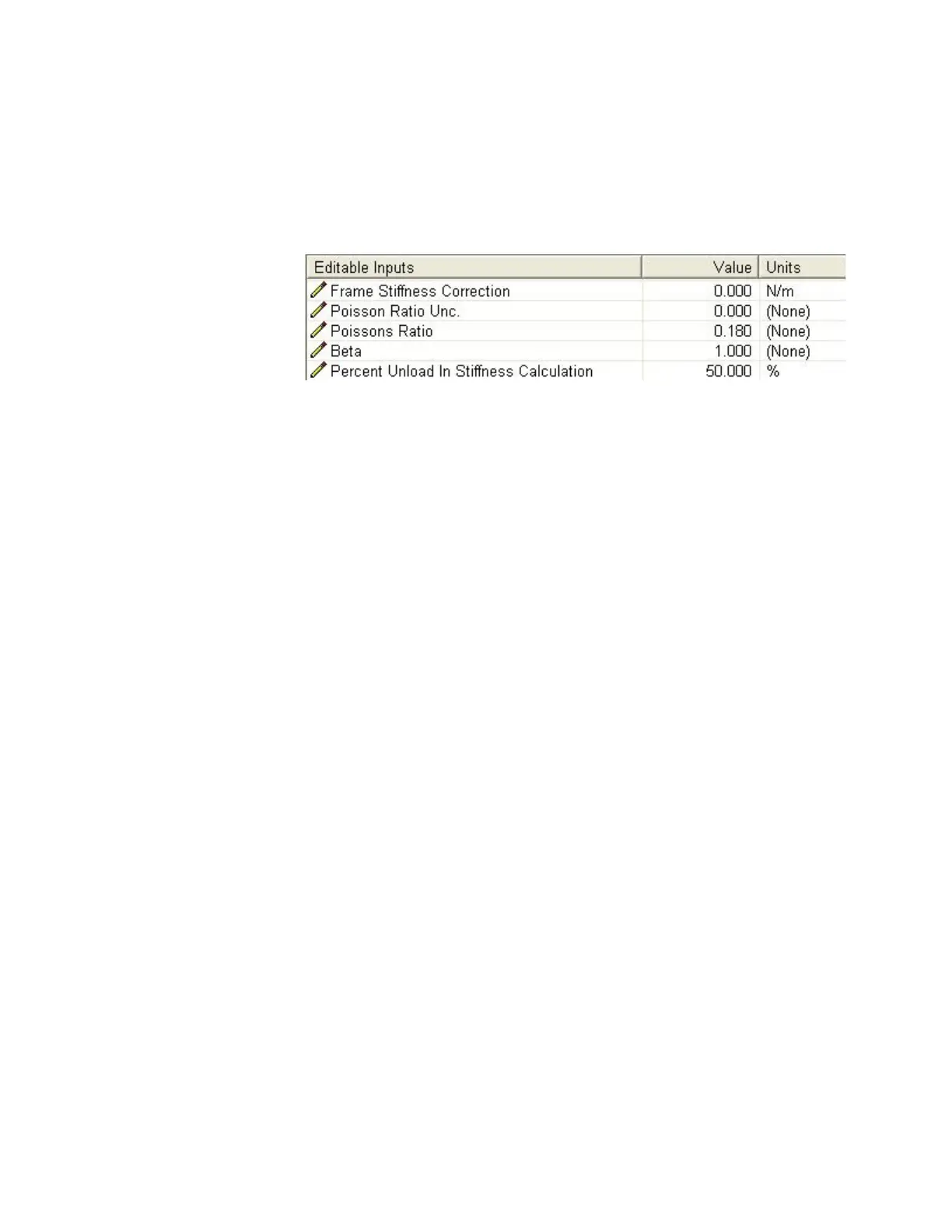

In order to manually adjust K

f

, change the value of Frame Stiffness

Correction listed under Editable Inputs on the Review Page as shown

in

Figure 7-9.

Figure 7-9Edit Frame Stiffness Correction value

Iteratively, adjust the correction value until modulus is constant with

depth. Incremental steps of ±10,000

N/m should be used first.

For samples where S > 0.1K

f

and hardness and elastic modulus are

expected to vary with applied force (i.e. thin film on substrate):

1 Determine K

f

using a bulk material, such as microscope-slide glass,

and the automated process, keeping the experimental set-up as

similar as possible to what will actually be used to test the sample of

interest.

2 Use the same head, tip, stage, sample position, puck type, adhesive,

and test method to determine frame stiffness as will be used to test

the sample.

Microscope slide glass is a good disposable material for this purpose,

because it is smooth, flat, uniform, isotropic, and inexpensive. Do not

mount/unmount the fused silica that was delivered with your instrument

to accomplish this task.

3 Mount samples in a manner that will maximize frame stiffness:

a Use either Crystalbond or epoxy; do not use double-sided tape.

b To use Al pucks again without heating samples:

• Heat the aluminum puck; use Crystalbond to adhere a glass

microscope slide to the top of the puck.

• Allow the glass-topped aluminum puck to cool.

• Epoxy samples to top glass.

• Test.

• Heat puck and remove glass with samples still adhered.

Aluminum puck is available to be re-used.

Loading...

Loading...