INSTALLATION AND STARTUP

1MANUL220 Belanger, Inc.® * PO BOX 5470. * Northville, MI 48167-5470 * Ph (248) 349-7010 * Fax (248) 380-9681 2-1

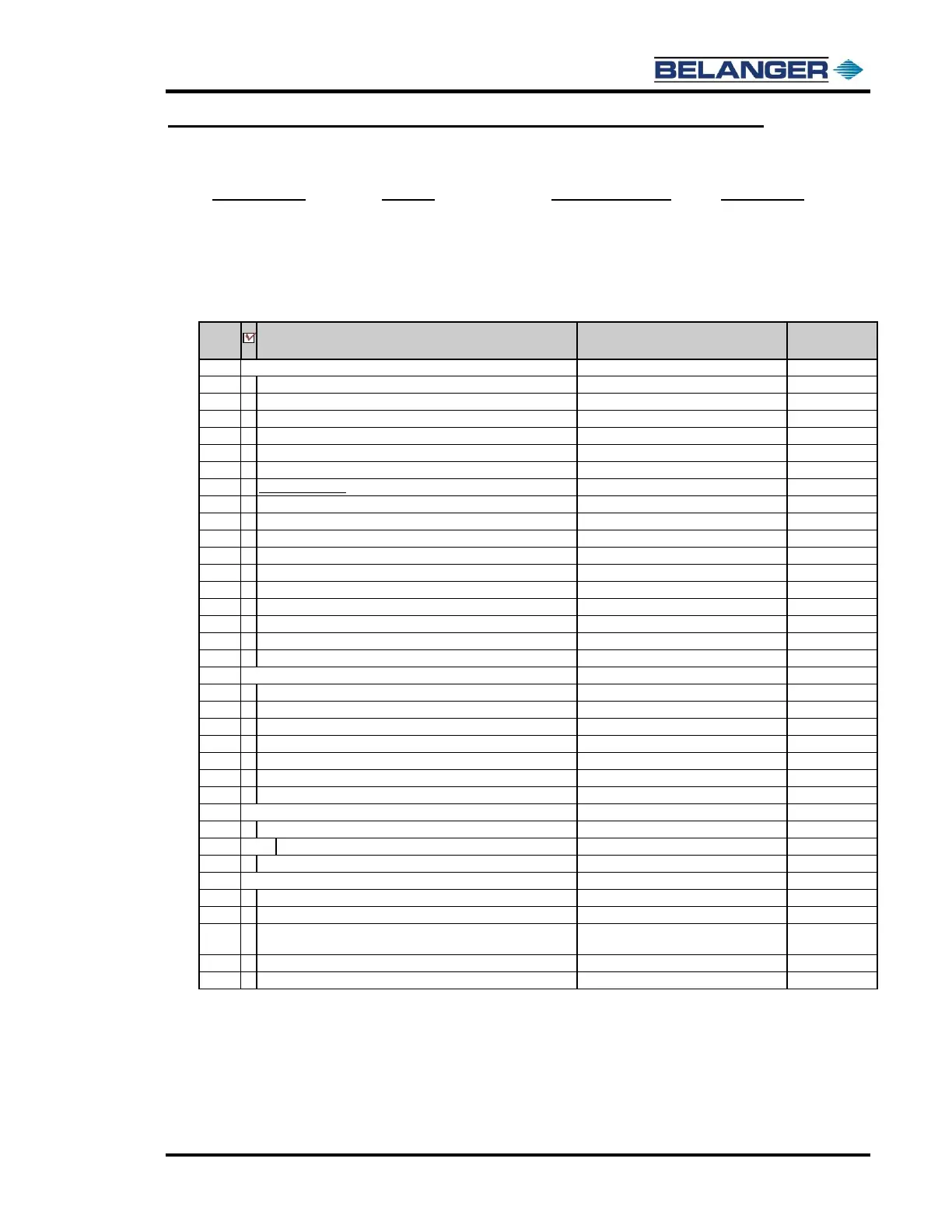

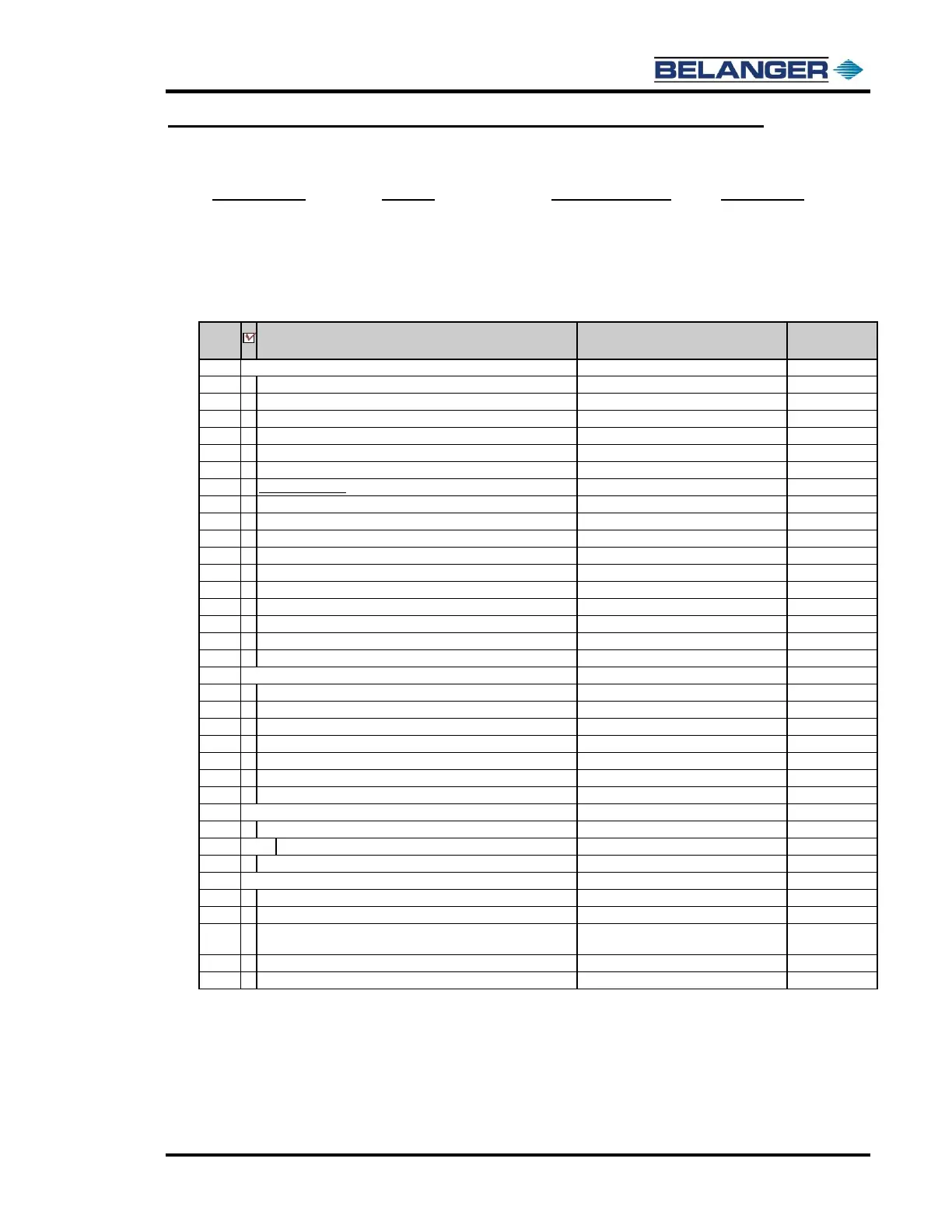

Chapter 2 Recommended Installation Sequence Checklist

Become Familiar with Site

Building dimensions:

Backroom dimension

• Bay area dimension

Location of:

Main water feed

Main Electrical feed

Determine proper location:

Air Drops

Wall Penetrations

E-Stops

Required Material:

• Anticipate runs and material

required to complete install

(i.e., salt for softener,

hydraulic hose assemblies)

Main Installation Checklist

Chapter and/or

Page Number(s)

DETERMINE EQUIPMENT LOCATIONS

Mount MCC and SCC Controller

Electrical & Initial Startup

Chemical Delivery & MixStir® Options

Position RO Unit and Tank

Electrical & Initial Startup

Mount HMI (E-1063 Human Machine Interface) or E-1063

Electrical & Initial Startup

MixStir® for Chemical Delivery

Wheel Cleaning and CTA Options

Optional Bug Spray Applicator

Reclaim modifications to Pumping station (if applicable)

Coordinate E-Stop Locations

Not Supplied by Belanger®

Electricians install conduits and wires

ERECT FREESTYLER® FRAMEWORK

Frame and Carriage Assembly

RAISE CARRIAGE ONTO RAILS

Frame and Carriage Assembly

Frame and Carriage Assembly

INSTALL BOOM MOUNT TO WALL

Frame and Carriage Assembly

Frame and Carriage Assembly

Plan System Component drain system

Including Air-Dump on compressor

Plumber installs hard plumbing

PLACE FLOOR ITEMS IN PROPER BAY LOCATION

Install Entrance Photo Eye

Entrance and Exit Photo-Eyes

Install Point of Entry System / POS in store

Not Supplied by Belanger®

Install Wait-Go / Navigational Signs

Frame and Carriage Assembly & Optional

Signage

Install Treadle and Bug Spray Option (if applicable)

Loading...

Loading...