INSTALLATION AND STARTUP

2-2 Belanger, Inc.® * PO BOX 5470. * Northville, MI 48167-5470 * Ph (248) 349-7010 * Fax (248) 380-9681 1MANUL220

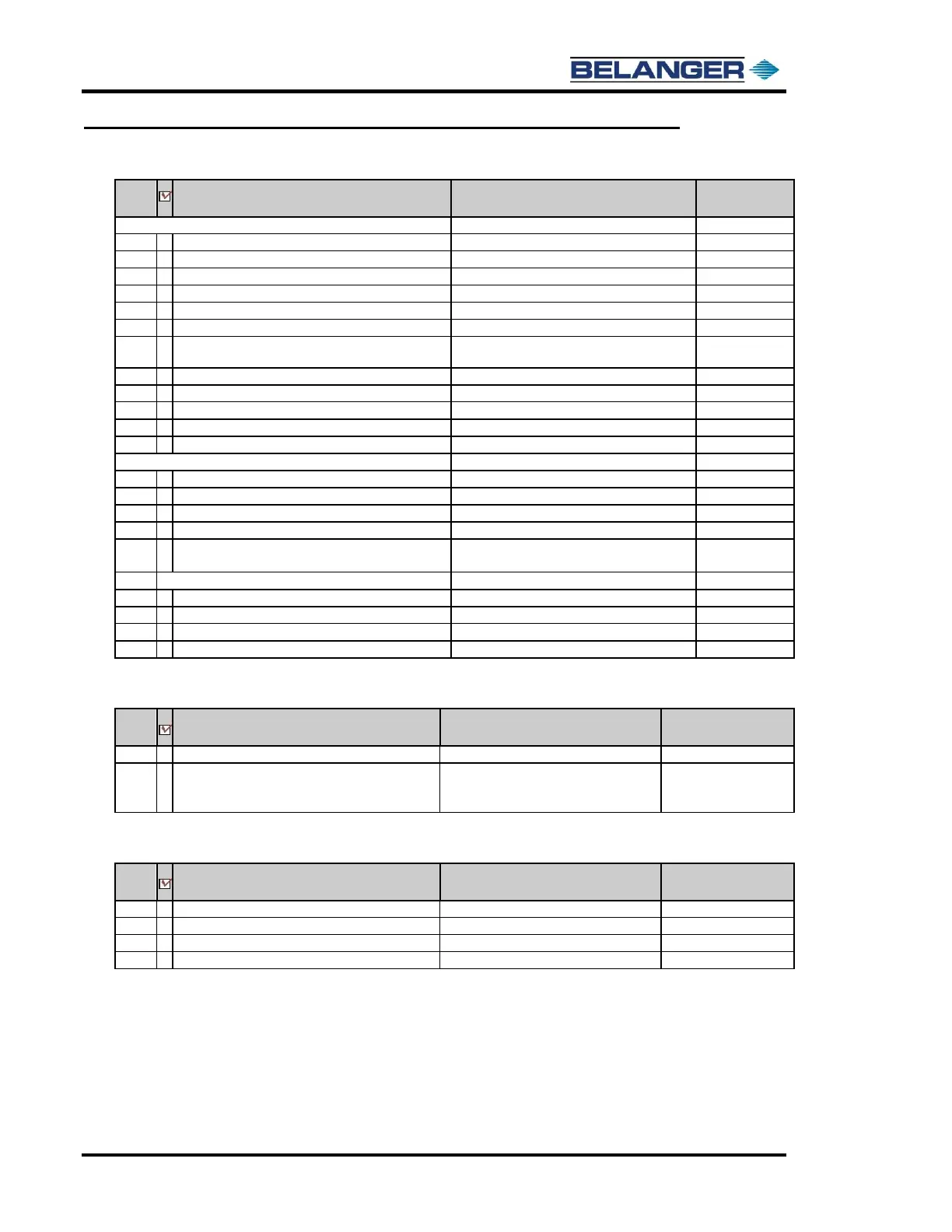

Chapter 2 Recommended Installation Sequence Checklist

Main Installation Checklist

Chapter and/or

Page Number(s)

ELECTRICIAN MOVES INSTALLATION TO BAY AREA

Electrical terminations made at MCC and SCC

Electrical & Initial Startup

Electrical terminations from Chemical Pumps to SCC

Chemical Delivery & MixStir® Options

Electrical terminations made at Pumping Station (Optional)

Electrical terminations made at RO Unit

Electrical terminations made at Dryer Panel

Electrical & Initial Startup

Electrical terminations made at Dryer

Electrical terminations made at HMI (E-1063 Human Machine

Interface)

Electrical & Initial Startup

Electrical terminations made to Treadle

Electrical terminations made at Photo Eyes

Entrance and Exit Photo-Eyes

Electrical terminations made at Entry Station / POS

Not Supplied by Belanger®

Electrical terminations made at Navigational Signs

Frame and Carriage Assembly & Optional Signage

Electrical terminations made at ALL E-Stops

Not Supplied by Belanger®

Install soft plumbing to Pumping Station (Optional)

Install soft plumbing to Chemical Pumps

Chemical Delivery & MixStir® Options

Install soft plumbing to Carriage

Frame and Carriage Assembly

Install soft plumbing to RO Unit

Install soft plumbing to Rocker Blaster / Undercarriage

Rocker Blaster, Rocker Spin Clean and

Undercarriage

Enterlink™ / Hamilton Setups P.O.S.

Not Supplied by Belanger®

Optional Onboard Dryer & Initial Startup

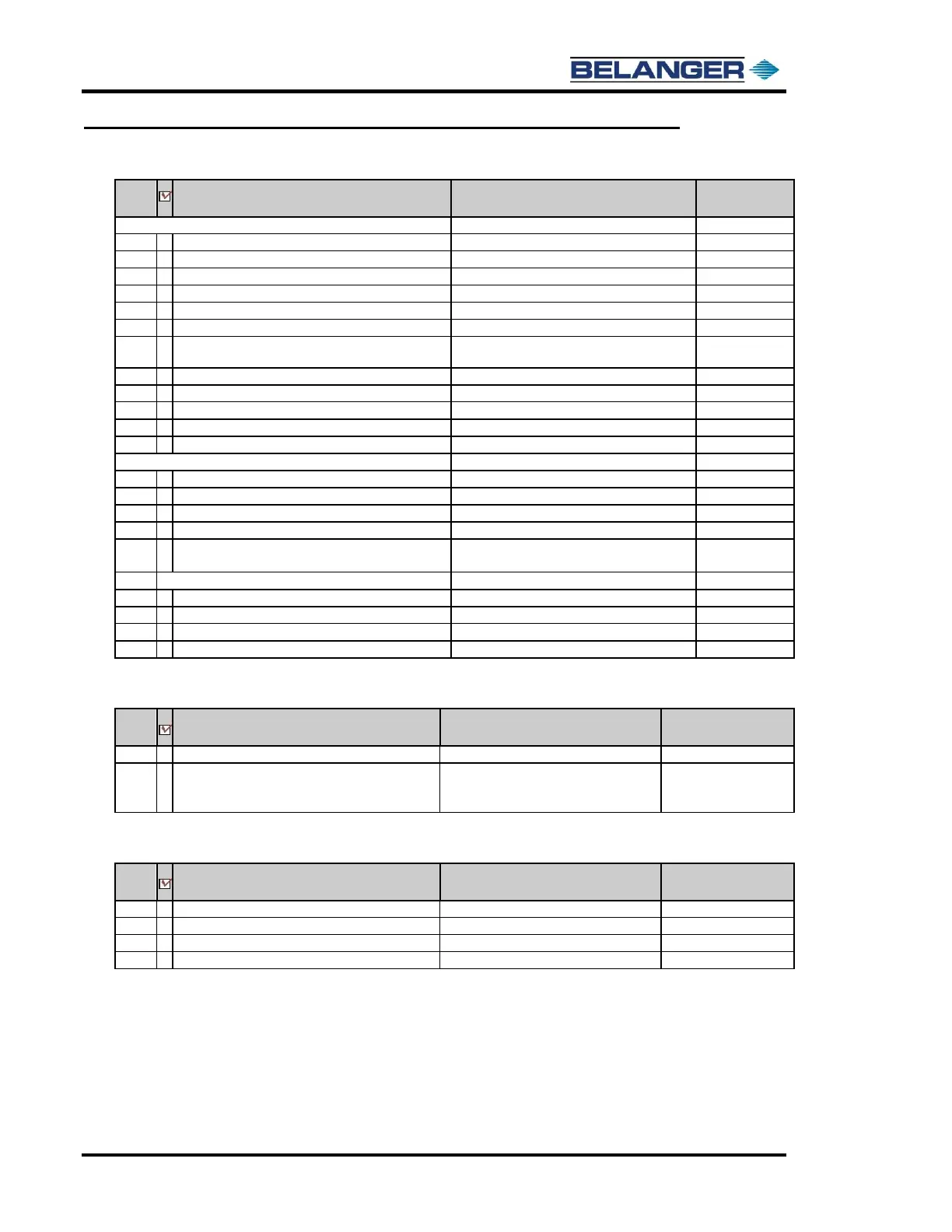

Optional Items to be Installed Anytime

Chapter and/or

Page number(s)

Undercarriage, Undercarriage with Rust Inhibitor, Bug

Spray Applicator, Triple Foam, Drying Agent, CTA, Wheel

Blaster, RO, Dually Treadle

See Individual Component Manuals

When Installation is Finalized

Chapter and/or

Page number(s)

Complete the Start Up Procedure

Optional Onboard Dryer & Initial Startup

Run Test Vehicles with customer

Customer Training on Operation

Loading...

Loading...