Chapter 22 Initial Startup

Check Inputs and Motion

Note: For the following checks, use the “Monitor Inputs” screen of the HMI (E-1063 Human

Machine Interface).

1) Check all inputs.

• Enter Door and Exit Door Photo-Eye

• Enter Load Photo-Eye

• Exit Load Photo-Eye

• All other installed Photo-Eyes

• Enter Load Sensor (Entrance Treadle Door)

• Exit load sensor (Exit Treadle Door)

• Carriage Encoder

Navigate to the JOG Screen on the HMI (E-1063 Human Machine

Interface).

Press CARRIAGE BACKWARD and verify that the machine moves

towards the entrance of the bay. If it moves the wrong way, swap your

motor leads at the MCC.

Press SLOW FORWARD while watching the CARR ENCODER

ovals. The oval pattern should move left-to-right while the machine is

moving slowly forward (see example at right). If the oval pattern

moves right-to-left, swap the Encoder Prox wires at the proximity

switches.

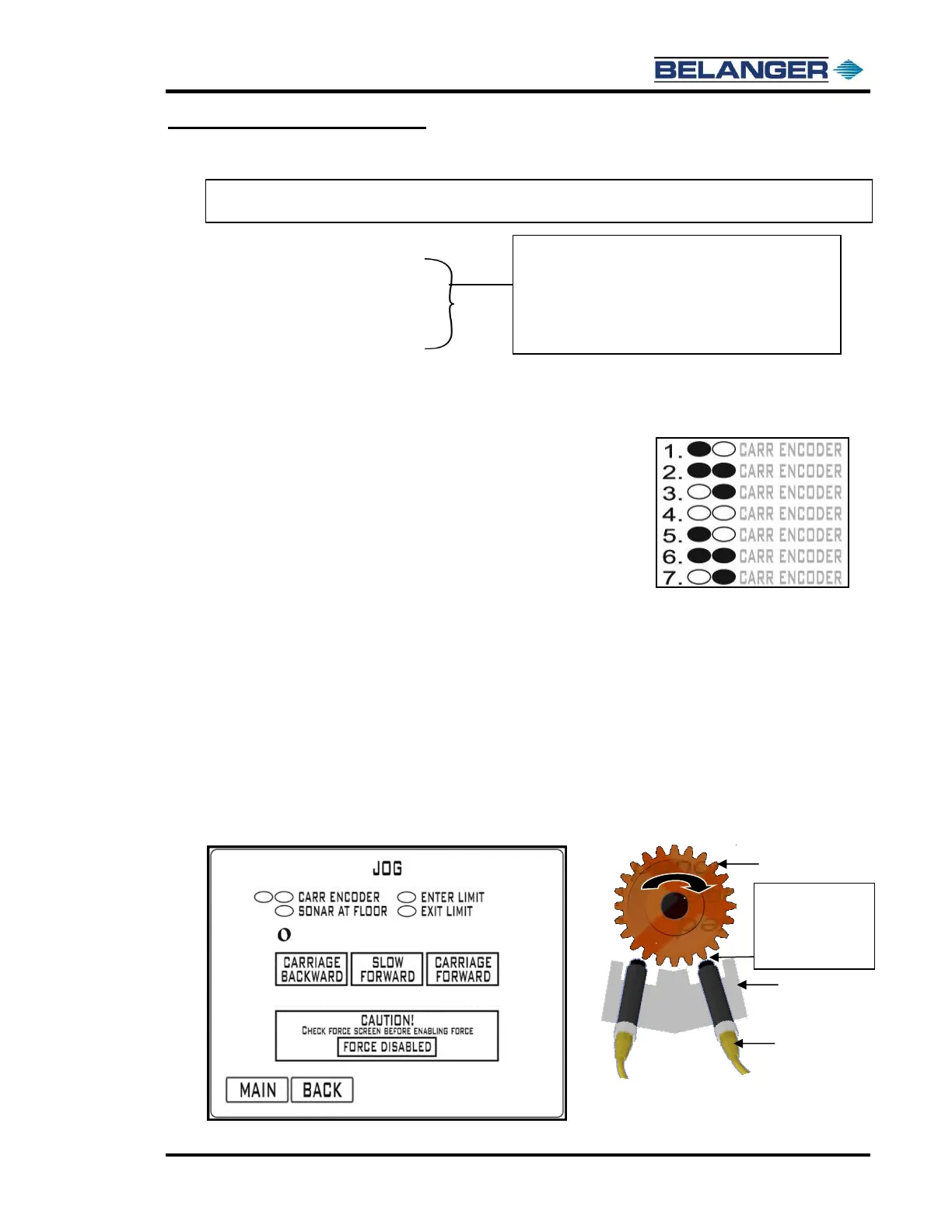

Encoder Proximity Switch Gap

Slow Forward: has been provided to check proper carriage Encoder operation.

Pressing the Slow Forward button first begins the Carriage moving slowly down the rails causing the gear in the

Encoder to turn. The ovals next to “CARR ENCODER” fill from left to right and clear from left to right.

If the oval fill/clear pattern is not according to the above, first check wiring. A typical fix if pattern is reversed is to swap

Proximity Cables on the Encoder.

Pressing and holding the SLOW FWD button will cause the display to appear for A and B Phase Encoder on times.

The proximity sensors should be adjusted until these are nearly identical.

Target Gap Distance will show on the HMI (E-1063 Human Machine Interface) Jog Screen. If needed make

adjustments by moving the Proximity Switch “IN” or “OUT” until the gap distance numbers below are achieved.

Remember to Push in the Emergency Stop Button if you are going into the Carriage to make adjustments!

Loading...

Loading...