INSTALLATION AND STARTUP

22-10 Belanger, Inc.® * PO BOX 5470. * Northville, MI 48167-5470 * Ph (248) 349-7010 * Fax (248) 380-9681 1MANUL220

Chapter 22 Initial Startup

De-Stroking Cylinder Arms

Overview

De-Stroking the cylinder arms is an option used in narrow bay applications. The arm cylinders should be de-stroked

when the media on a wheel interferes with the wall of the wash. De-Stroked Arms will require Bumper Extensions.

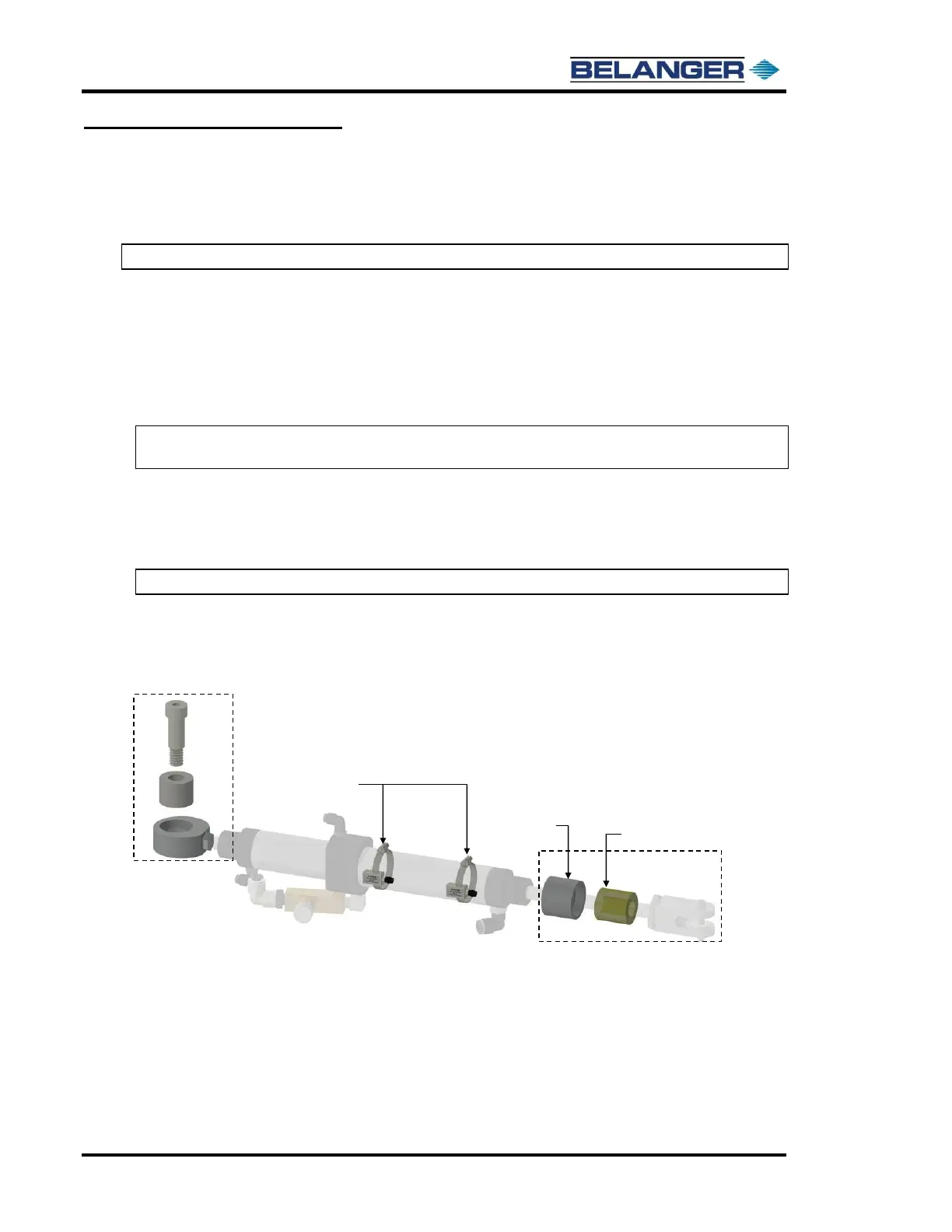

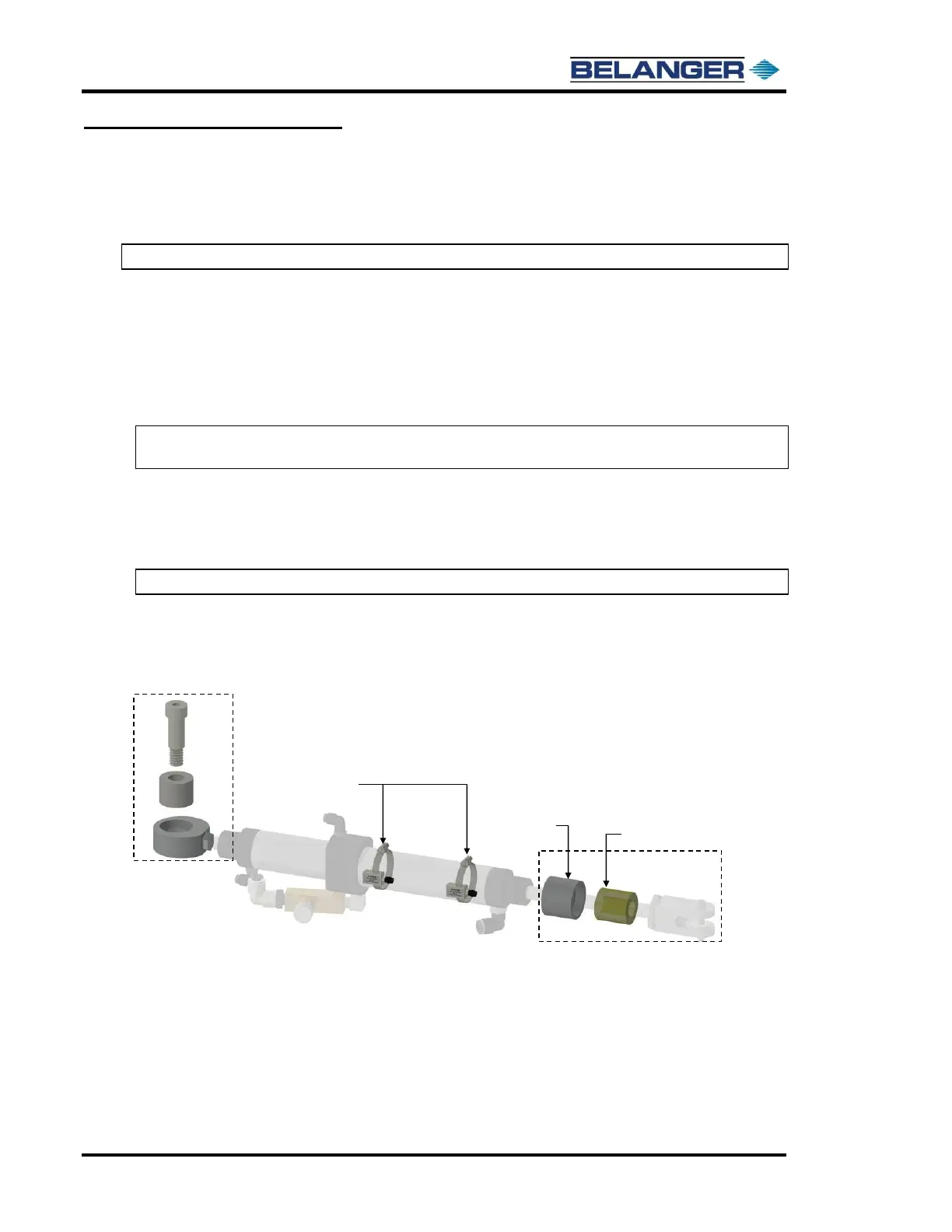

Note: Keep in mind that the entrance and exit arms require different components.

• The entrance arms use Entrance Cylinder Stop (Belanger® part # 7300)

• The exit arms use Exit Cylinder Stop (Belanger® part # 7340).

• Both entrance and exit arms use Posi-Stop (Belanger® part # 7310).

• See the images below for identification.

Entrance Arm Cylinder

Using a wrench, remove the cylinder rod so that the clevis stays attached.

Note: DO NOT USE PLIERS, VISE-GRIPS OR ANY OTHER TOOL THAT WILL DAMAGE

THE CYLINDER ROD. THIS DAMAGE WILL CAUSE CYLIDER FAILURE.

Slide the Posi-Stop into the Limit Stop.

Slide the Posi-Stop and Limit Stop over the rod.

Thread the Limit Stop onto the cylinder and tighten it down with light pressure.

Use a wrench to tighten the rod back onto the clevis.

Note: Take care not to cross-thread the rod and clevis.

Pull the arm in to press the Posi-Stop into the Limit Stop.

Make sure all connections are completely tightened.

Adjust the Reed Switch accordingly. See Resetting the Cylinder Reed Switches later in this section.

Repeat the process on the other arm if necessary, to clear any obstructions.

Loading...

Loading...