Commissioning

6.7.8 Torque control

The Torque control can be used in applications where a torque should be used as reference value

instead of a frequency.

Via parameter

n/T Control Change-Over 164 a jerk less switch over from Speed Control to Torque

Control is possible.

100 % Torque refer to the calculated Torque from

Rated Mech. Power 376 (Motor power) and Rated

Speed

372 (Motor nominal speed).

The Torque control is only available in configurations 410 FOC and 610 SYNC.

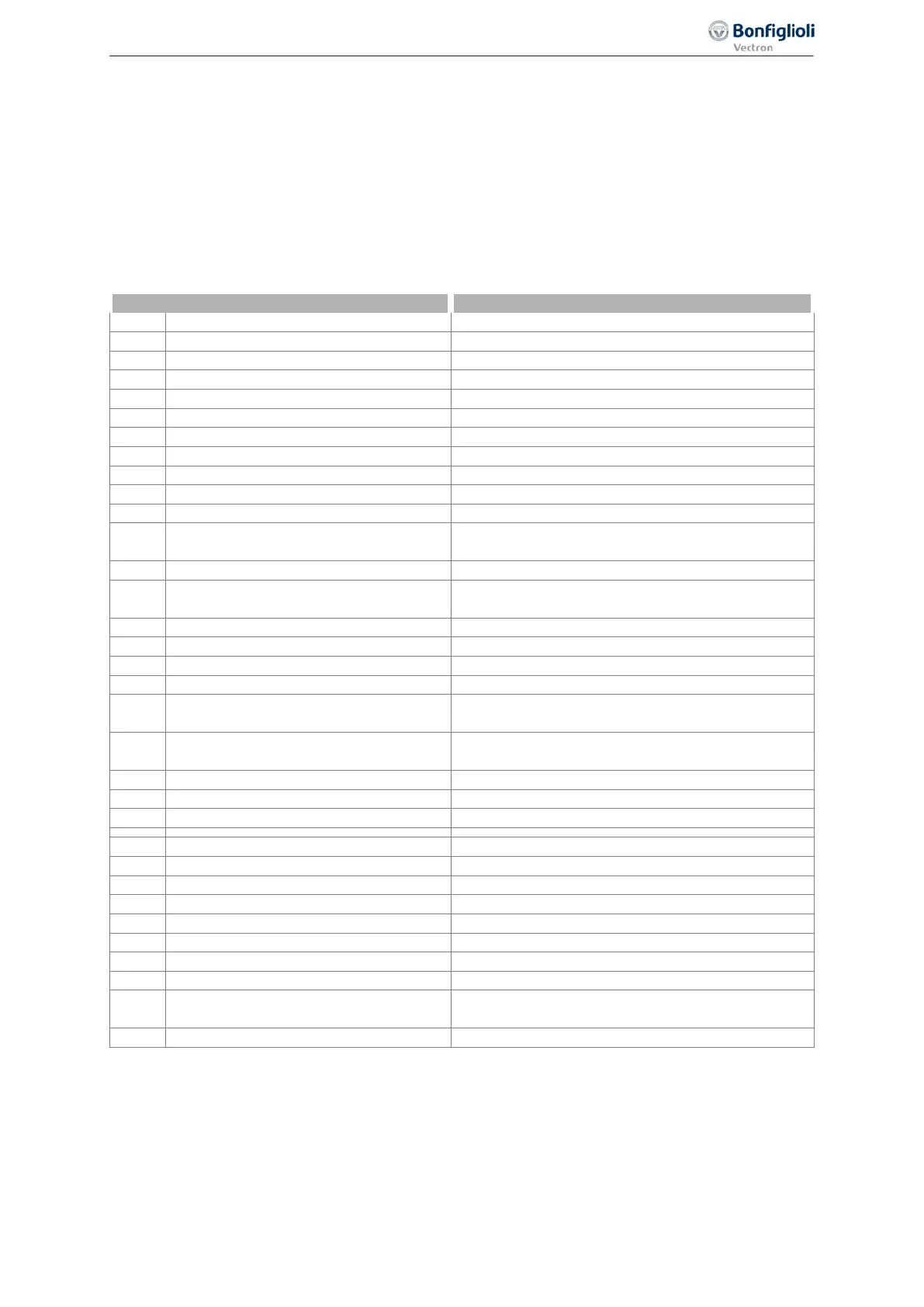

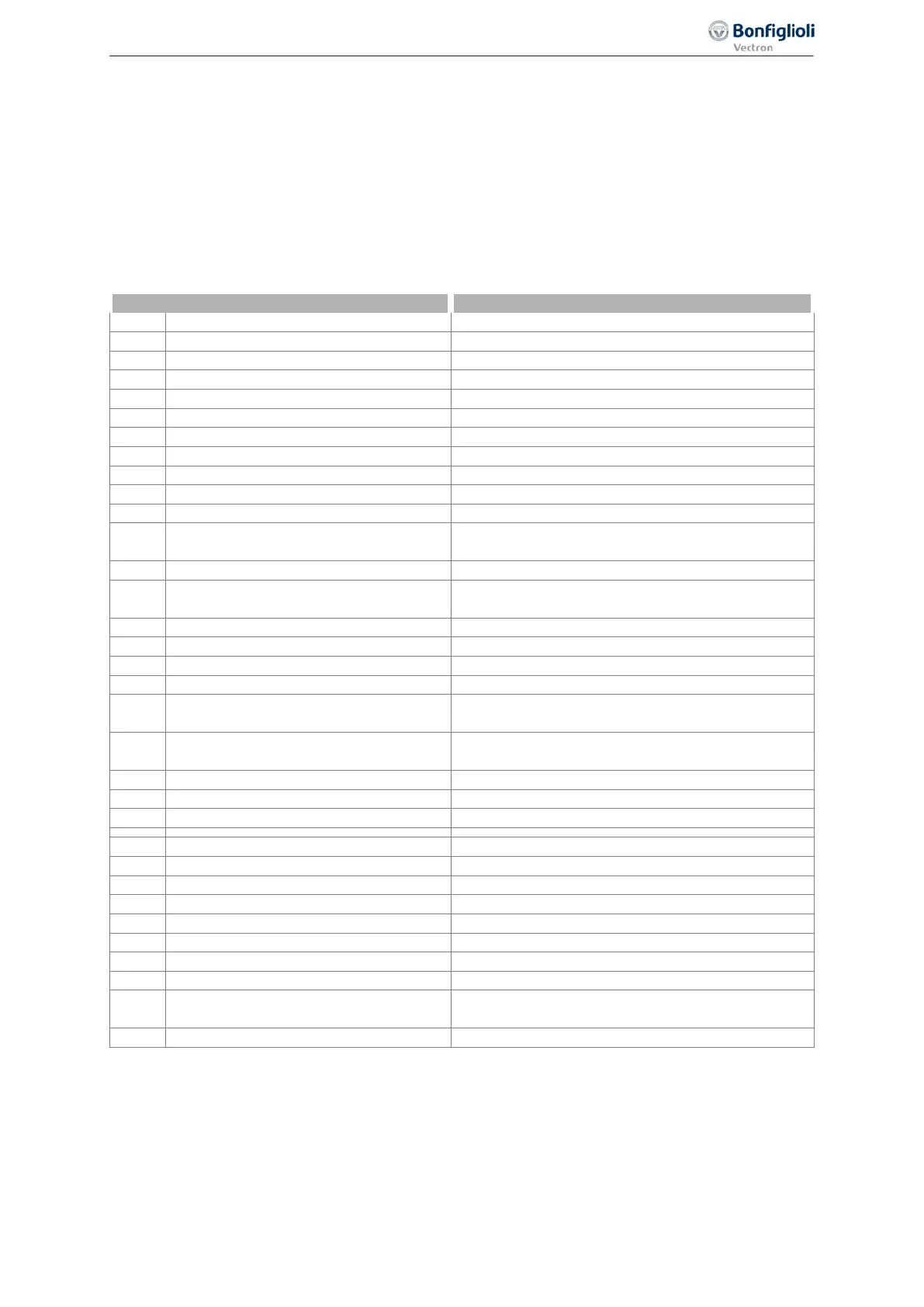

Reference frequency source 1

Reference percentage source 1

Reference frequency source 2

493

Operation mode (reference frequency

source)

Reference percentage source 2

495

Operation mode (reference percentage

source)

Minimum reference percentage

Maximum reference percentage

562

Operation Mode MFI2 (Multifunction

input 2)

630

Operation mode (P68&P69=1

|P68&P69=0) (stopping behavior)

0 - (Coast to Stop | Coast to Stop)

Operation mode (auto start)

Fixed frequency Change-Over 1

Fixed frequency Change-Over 2

Fixed percent Change-Over 1

Fixed percent Change-Over 2

531

Operation mode OUT1D (X13.5) (digital

output)

Operation mode OUT2D (X10/relay)

1) The setting -0.01 Hz effects the usage of the same ramp like stated in Parameters

Acceleration

Clockwise

420.

1) Bonfiglioli Vectron recommends to set

Minimum frequency 418 > Frequency limit 624. Comply

with the notes in chapter 7.9.5.2 “Torque controller”.

107

Applications 06/2013 Operating Instructions

Agile

Loading...

Loading...