Electrical Installation

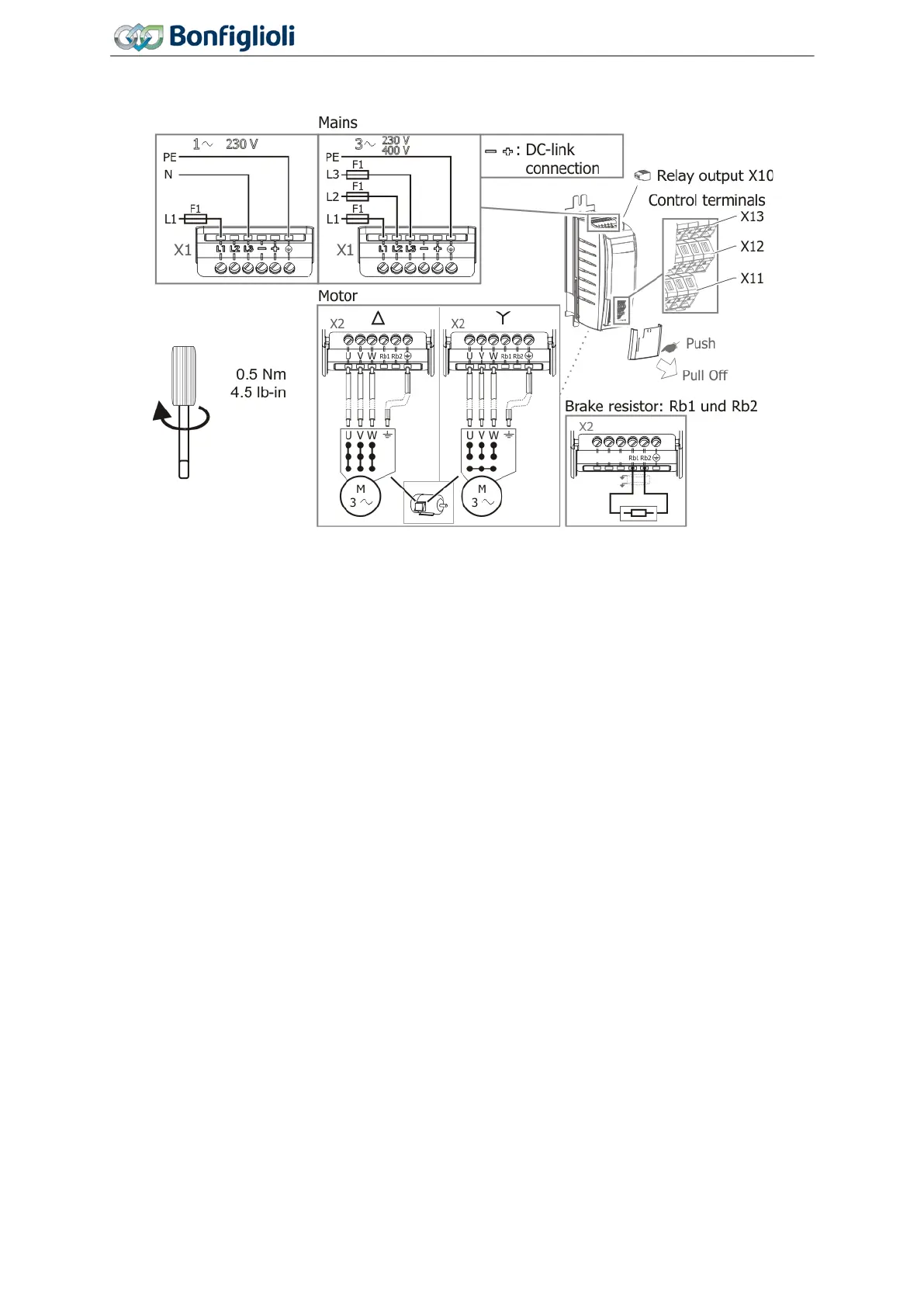

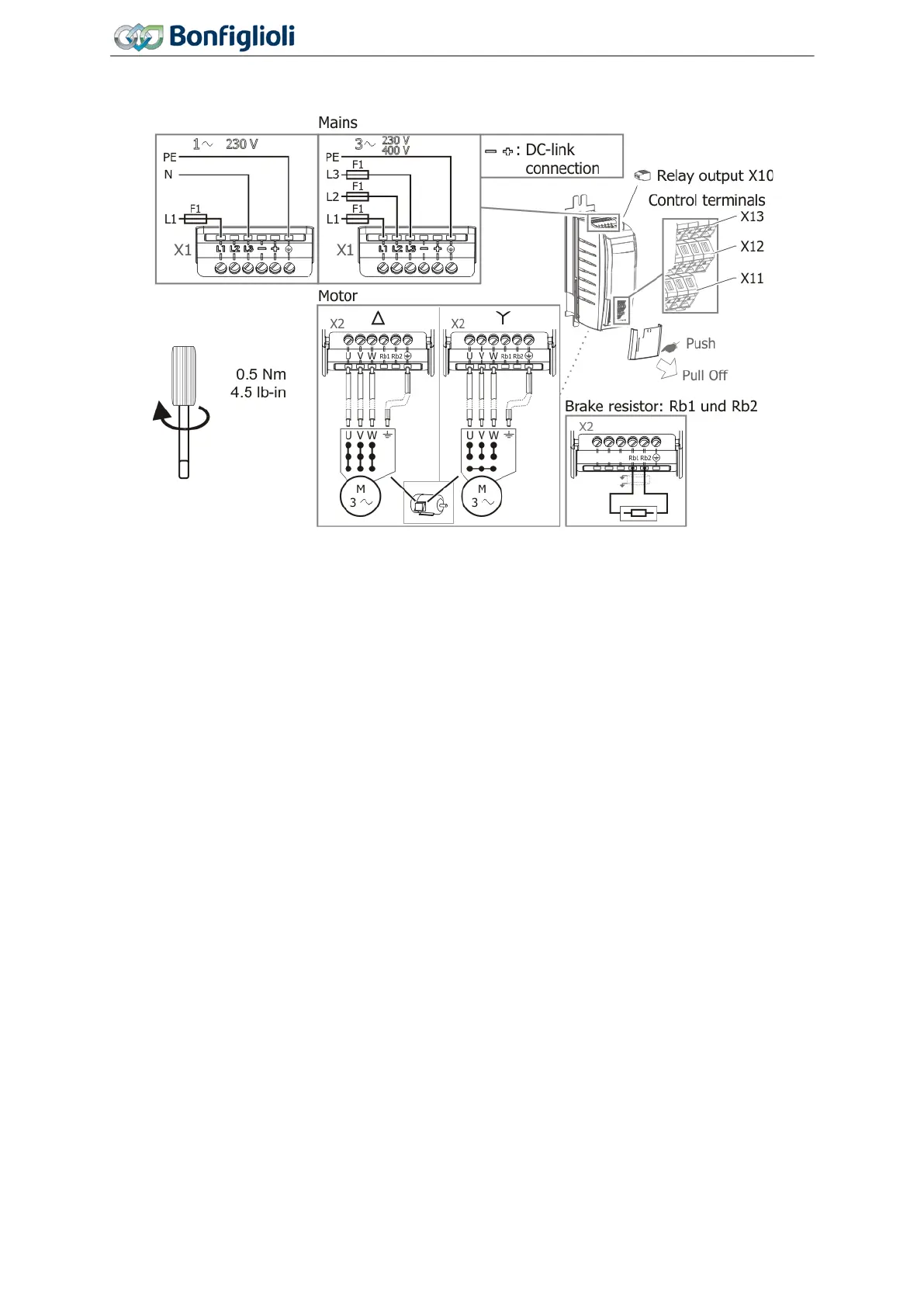

5.2 Electrical connections overview

For connection refer to the corresponding chapter.

5.3 EMC Information

The frequency inverters are designed according to the requirements and limit values of product norm

EN 61800-3 with an interference immunity factor (EMI) for operation in industrial applications. Elec-

tromagnetic interference is to be avoided by expert installation and observation of the specific product

information.

Measures

• Install the frequency inverters on a metal mounting panel that is connected to the equipotential

bonding. Ideally, the mounting panel should be galvanized, not painted.

• Provide proper equipotential bonding within the plant. Plant components such as control cabinets,

control panels, machine frames must be connected to the equipotential bonding by means of low

inductive wire mesh.

• Connect the shields of the cables on both sides to the mounting panel that is not painted and

connected to the equipotential bonding.

• Connect the shield of analog control cables to the equipotential bonding only on one side near to

the frequency inverter.

• Connect the frequency inverter and other components, e.g. external filters and other components

to the equipotential bonding via short cables.

• Keep the cables as short as possible; make sure that cables are installed properly using appropri-

ate cable clamps, etc.

• Contactors, relays and solenoids in the electrical cabinet are to be provided with suitable interfer-

ence suppression components.

32

Operating Instructions

Agile

06/2013 Electrical connections overview

Loading...

Loading...