Options

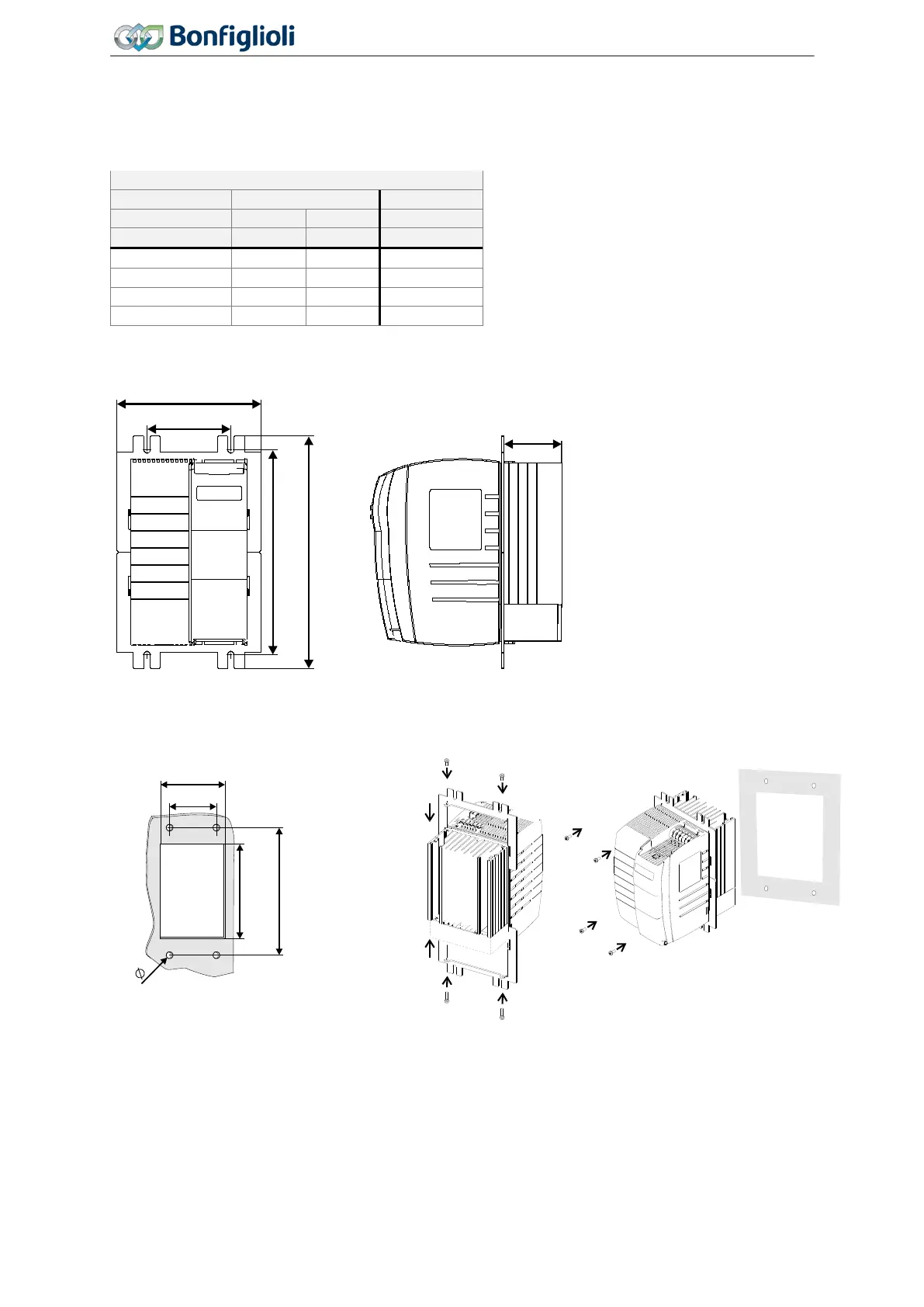

12.9.1.4 Size 3 (5.5 kW to 11.0 kW)

12.9.1.4.1 With heat sink fan

Valid for the following devices

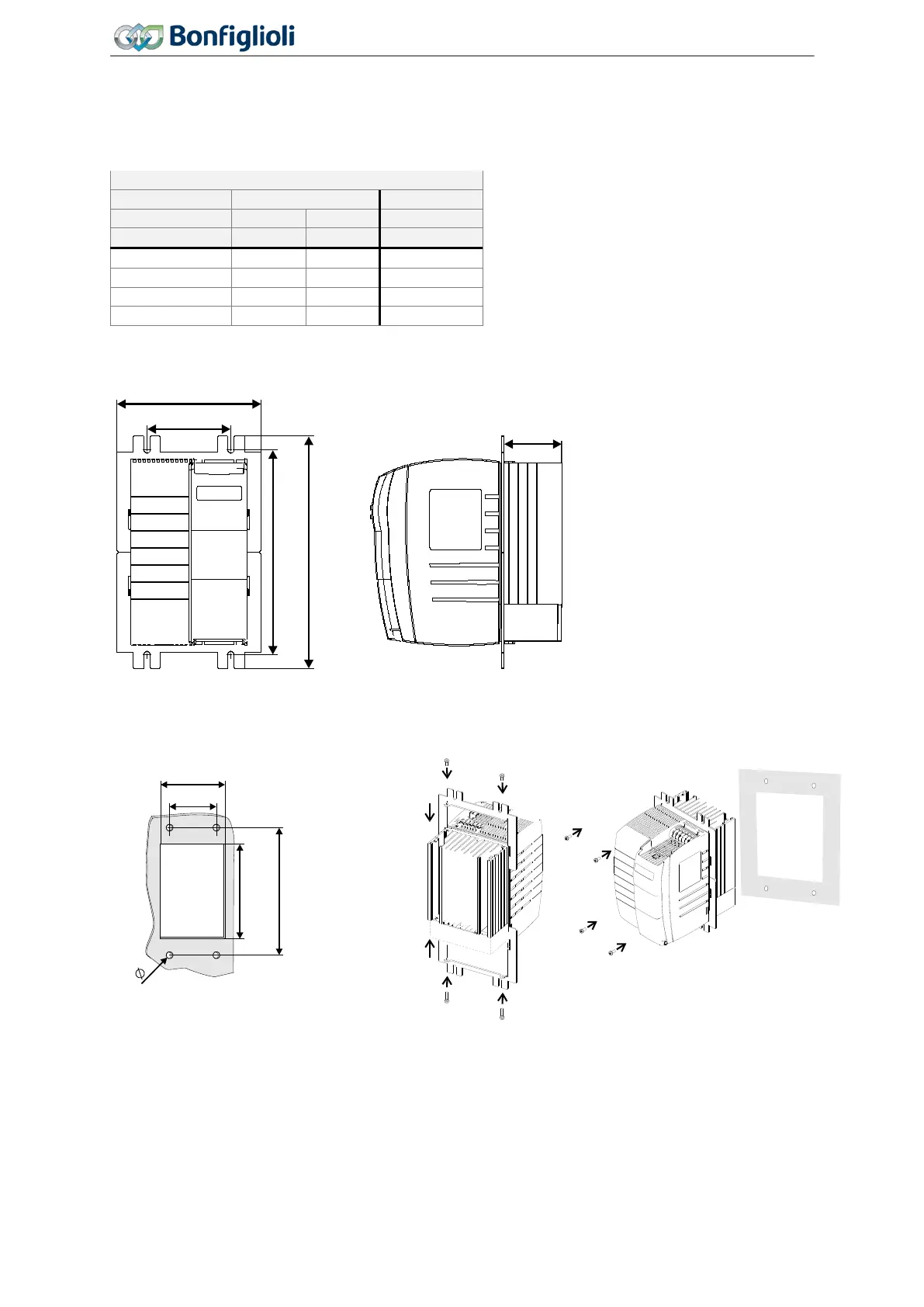

Place a seal between frequency inverter and mounting plate.

Use screws M6 with minimum length 30 mm.

312

Operating Instructions

Agile

06/2013 Assembly variants

Loading...

Loading...