Commissioning

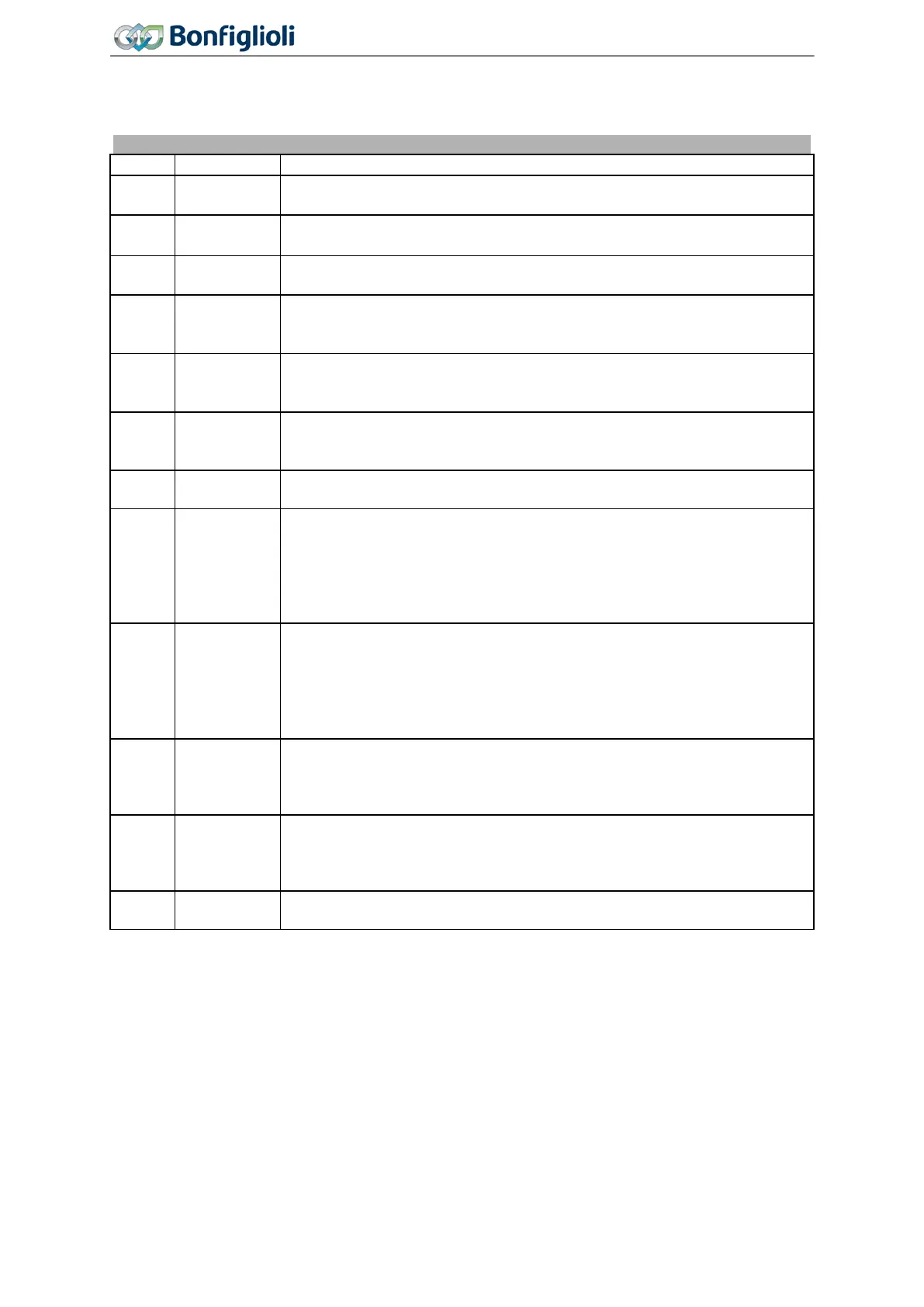

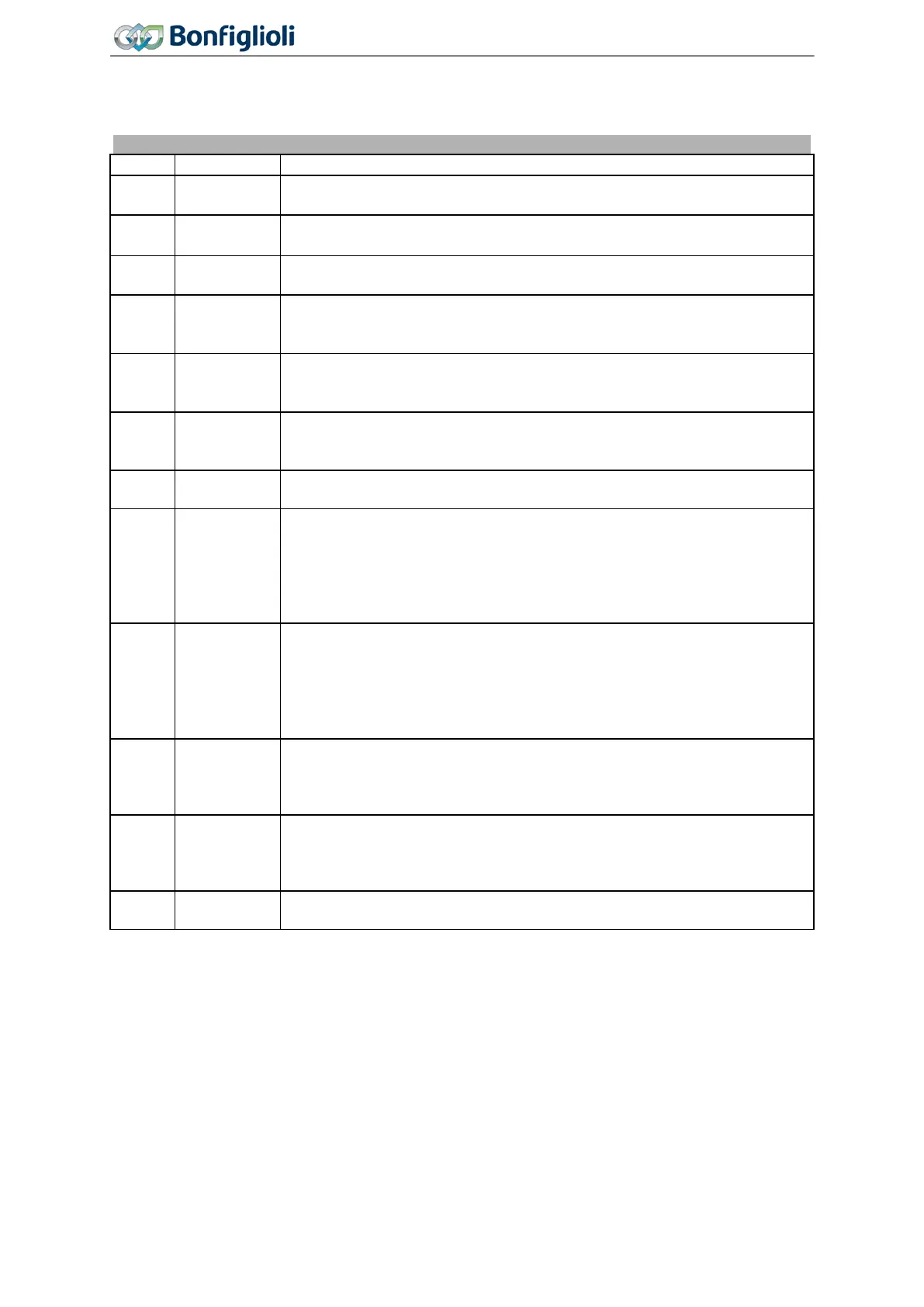

6.2.6 Error messages during commissioning (SF…)

If an error or a warning is signaled during commissioning, the following causes are possible.

SF001

The value entered for parameter Rated Current 371 is too low. Correct the

value.

SF002

too high

The value for parameter Rated Current 371 is too high, referred to param-

eters Rated Power 376 and Rated Voltage 370. Correct the values.

SF003 Rated cos-phi

The value entered for parameter Rated Cosine Phi 374 is wrong (greater

than 1 or smaller than 0.3). Correct the value.

SF004

Negative slip

frequency

The calculated slip frequency is negative. Check and, if necessary, correct

the values entered for parameters Rated Speed 372 and Rated Frequency

SF005

Slip frequen-

cy too high

The calculated slip frequency is too high. Check and, if necessary, correct

the values entered for parameters Rated Speed 372 and Rated Frequency

SF006

Power bal-

ance

The calculated total output of the drive is lower than the rated power. Cor-

rect and check, if necessary, the value entered for parameter Rated Power

SF007

The set configuration is not supported by the set-up routine.

SF011

Inductance

measurement

failed

The main inductance measurement has failed because the motor has a high

slip. Correct the rated motor values in parameters 370, 371, 372, 374,

375 and 376. Carry out the set-up routine again. In case an error message

is displayed again, enter the value 110 for parameter

Configuration 30

(sensorless control according to V/f-characteristic) if value 410 was set so

far. Carry out the set-up routine again.

SF012

Inductance

measurement

failed

The leakage inductance measurement has failed because the motor has a

high slip. Correct the rated motor values in parameters 370, 371, 372,

374, 375 and 376. Carry out the set-up routine again. In case an error

message is displayed again, enter the value 110 for parameter

Configura-

tion

30 (sensorless control according to V/f-characteristic) if value 410 was

set so far. Carry out the set-up routine again.

SF021

Resistance

measurement

failed

The measurement of the stator resistance did not deliver a plausible value.

Check the cables at the terminals of the motor and the frequency inverter

for proper connection and check the contacts for corrosion and safe con-

tact. Carry out the set-up routine again.

SF022

Resistance

measurement

failed

The measurement of the rotor resistance did not deliver a plausible value.

Check the cables at the terminals of the motor and the frequency inverter

for proper connection and check the contacts for corrosion and safe con-

tact. Carry out the set-up routine again.

SF026

The setup-routine is aborted.

If an error or a warning is signaled:

− Press ESC to correct a parameter value after an error message or warning.

− Press ENT to suppress a warning message. Setup is continued. It is recommended that the entered

data be checked.

In the case of problems not triggering an error message, you can try to find an appropriate measure,

following the instructions in chapter 13.3 "Troubleshooting".

If errors or warning messages occur during operation, proceed according to the instructions in chap-

ters 13.1.1 "Error messages" and 14.3 "Warning status and warning status application".

70

Operating Instructions

Agile

06/2013 First commissioning

Loading...

Loading...