Parameter descriptions

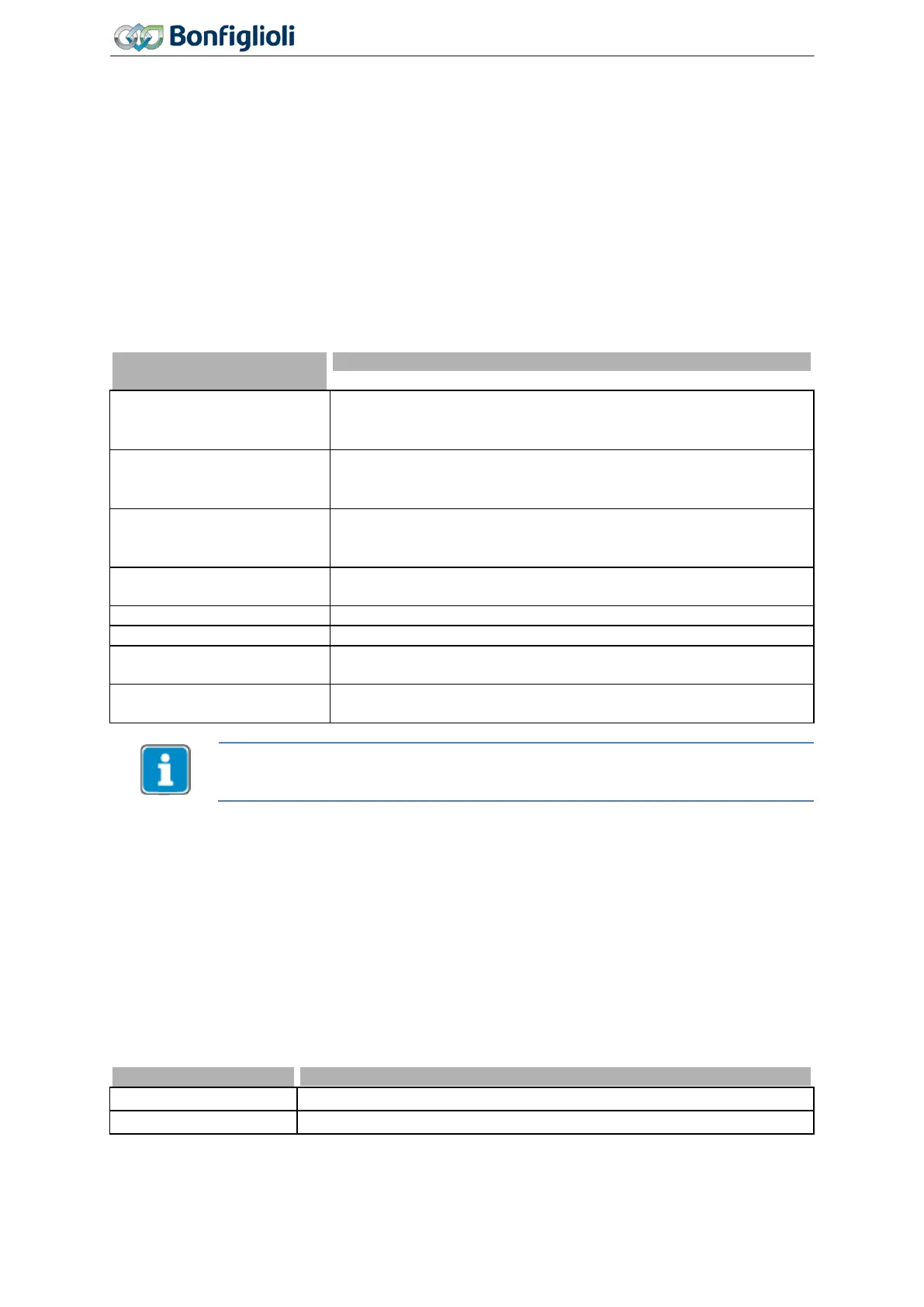

7.9.5.3.2 Limit value sources

734 Isq Limit Source Motor Operation

735 Isq Limit Source Generator Op.

736 Torque Limit Source Motor Op.

737 Torque Limit Source Gen. Op.

As an alternative to limiting the output values by a fixed value, linking to an analog input value is also

possible. The analog value is limited via parameters

Minimum Reference Percentage 518, Maximum

Reference Percentage

519, but does not consider the Gradient Percentage Ramp 477 of the refer-

ence percentage value channel.

The assignment is done with the help of the parameters

Isq Limit Source Motor Operation 734 and

Isq Limit Source Generator Op. 735 for the torque-forming current component Isq.

The sources for the torque limits can be selected via the parameters

Torque Limit Source Motor Op.

736 and Torque Limit Source Gen. Op. 737.

Operation mode

734, 735, 736, 737

101 - Analog Input MFI1A

Multifunction input 1 is the source. Via parameter Operation Mode

MFI1 452, multifunction input 1 must be set up as a voltage or

102 - Analog Input MFI2A

Multifunction input 2 is the source. Via parameter Operation Mode

MFI2 562, multifunction input 2 must be set up as a voltage or

105 -

Repetition Percentage

Input

The percentage signal at the repetition frequency input (IN2D, ter-

minal X11.5). Operation Mode IN2D 496 must be set to 20 or 21.

See chapter

7.6.7 "Input PWM/repetition frequency/pulse train".

110 - Fixed Limit

The selected parameter figures for limiting the speed controller are

taken into account. Factory setting.

Process data of the system bus. Refer to instructions on system bus.

Process data of the system bus. Refer to instructions on system bus.

2521 -

Output value of a PLC-function. Refer to application manual “PLC”.

2522 -

Output value of a PLC-function. Refer to application manual “PLC”.

The limit values and assignment to different limit value sources are data set related in

the configurations. The use of the data record changeover demands an examination of

the parameters in question.

7.9.5.3.3 Switching over between speed control and torque control

Via the signal assigned to parameter

n-/T-Control Change-Over 164, you can switch between speed

control and torque control. See chapter 7.6.6.10 "n-/T-control changeover".

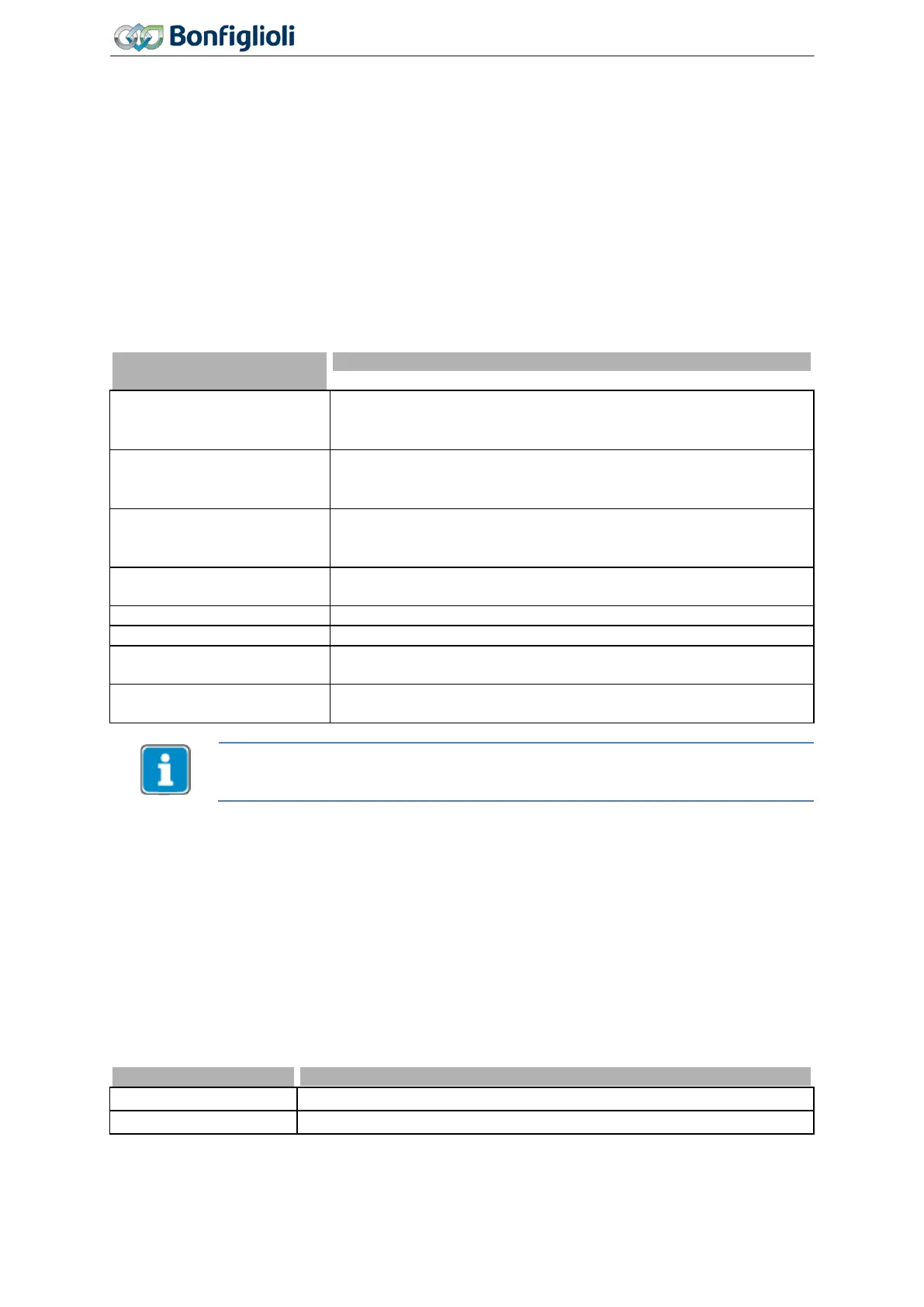

7.9.5.4 Acceleration pre-control

725 Operation Mode

The acceleration pre-control controlled parallel to the speed controller reduces the reaction time of the

drive system to a change of reference values.

The acceleration pre-control is active in the speed-controlled configurations and can be activated via

parameter

Operation Mode 725.

The control system is not influenced. Factory setting.

The acceleration pre-control is active according to the limit values.

236

Operating Instructions

Agile

06/2013 Control functions

Loading...

Loading...