Electrical Installation

5.6 Motor Connection

DANGER

Disconnect the frequency inverter from mains voltage and protect it against being ener-

gized unintentionally.

Verify that the frequency inverter is discharged.

Wait for some minutes until the DC link capacitors have discharged before starting to

work at the unit.

When the frequency inverter is disconnected from power supply, the mains, DC-

voltage and motor terminals may still be live for some time.

When using pluggable terminals: Do not switch on the device while the plugs are dis-

connected, the IP protection is only warranted with plugged terminals.

BONFIGLIOLI recommends connecting the motor to the frequency inverter using shielded cables.

• Connect the cable shield to PE potential properly, i.e. with good conductivity, on both sides.

• The motor cables must be kept physically separate from the control and network cables.

The user must comply with the applicable limits stipulated in the relevant national and international

directives as regards the application, the length of the motor cable and the switching frequency.

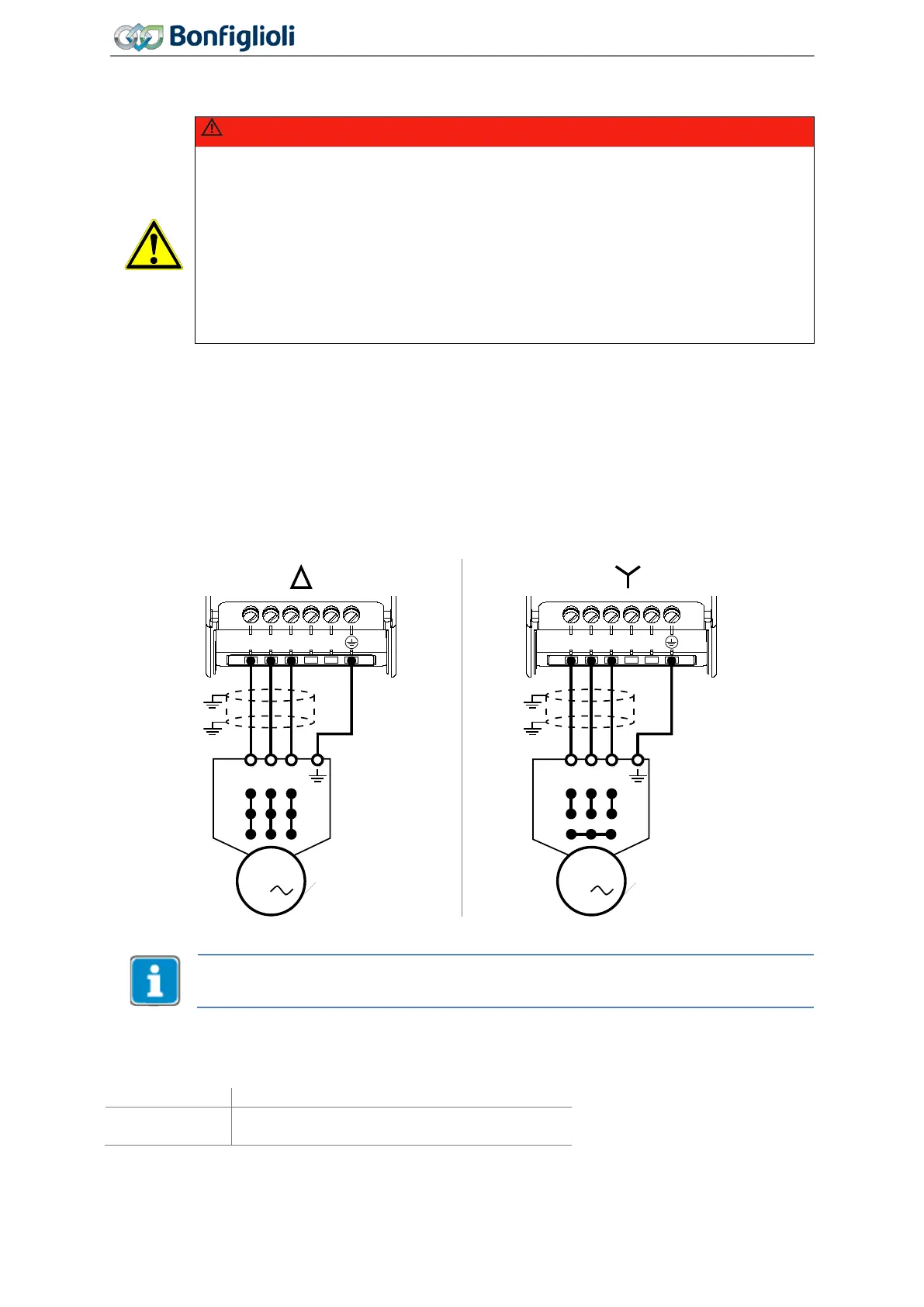

Connect in delta connection or star connection according to the motor data.

Minimum Torque to tighten the screws: 0.5 Nm (4.6 lb-in)

Maximum

Torque to tighten the screws: 0,6 Nm (5,3 lb-in)

Comply with the notes on cable cross-sections in chapter 5.4 "Dimensioning of conductor cross-

section"

Motor terminals:

0.2 … 4 (flexible cable with sleeve)

0.2 … 6 (rigid cable)

W

M

3

VU

W

M

3

VU

U

U

V

V

W

W

Rb1

Rb1

Rb2

Rb2

X2X2

38

Operating Instructions

Agile

06/2013 Motor Connection

Loading...

Loading...