Commissioning

6.8 Set-up via the Communication Interface

796 SETUP Selection

Parameter-setting and commissioning of the frequency inverter via one of the communication inter-

faces include the plausibility check and the parameter identification functions. The parameter selection

during the guided commissioning procedure includes the basic parameters. These are based on

standard applications and support commissioning.

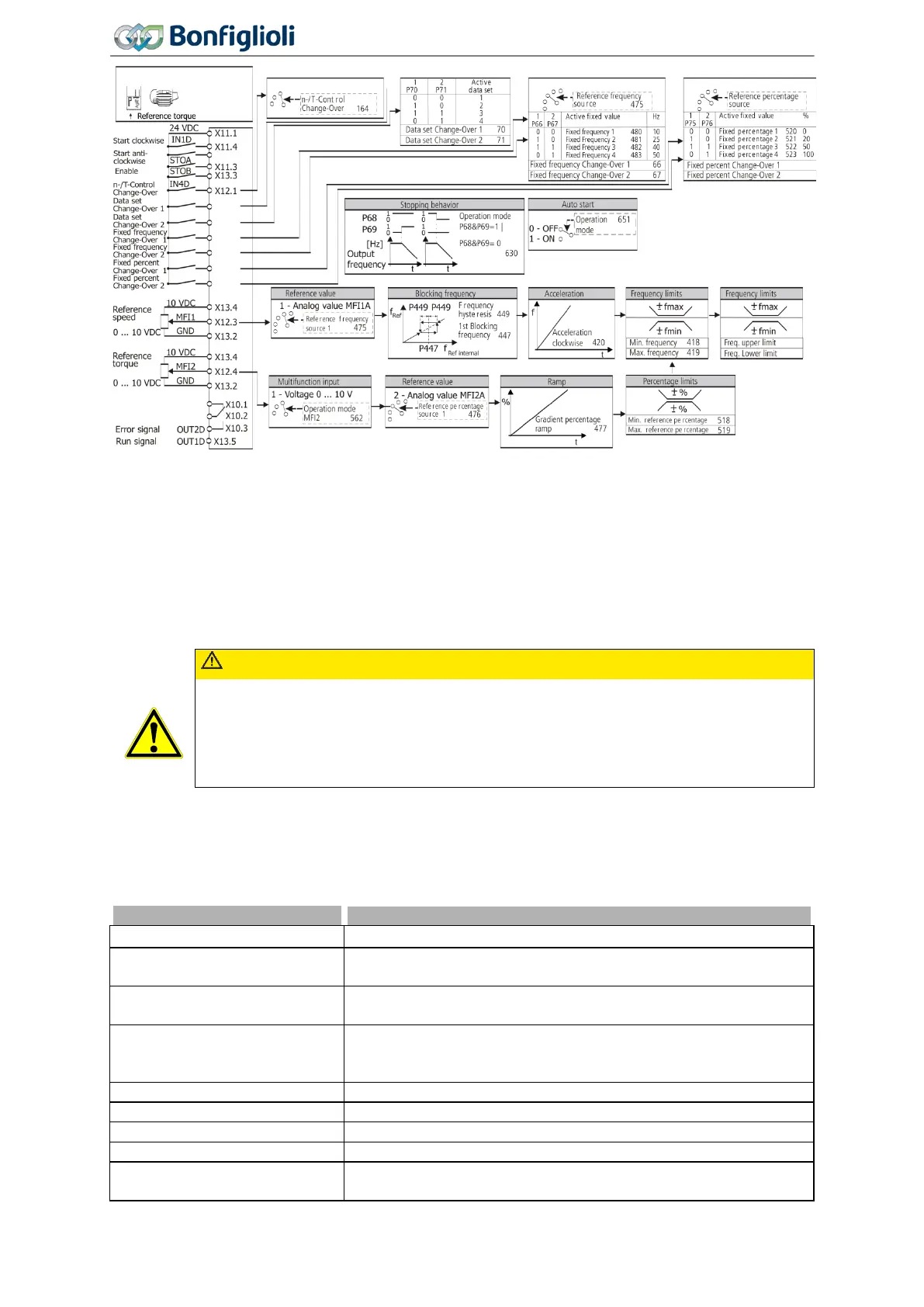

CAUTION

Parameter settings may only be changed by qualified staff. Before starting the commis-

sioning process, read the documentation and comply with the safety instructions.

At the beginning of the auto set-

up of a synchronous motor, the motor shaft will be

aligned when enable is switched on. It must be ensured that, personal or material dam-

age is excluded.

For parameter

SETUP Selection 796, choose a function.

The function will be executed as soon as enable is switched on at digital inputs STOA and STOB.

The functions are also carried out automatically one after the other during the guided commissioning

procedure.

0 -

Clear Status The auto set-up routine does not perform a function.

1 -

Continue

The warning message is acknowledged and the auto set-up rou-

tine is continued.

2 -

Abort

The auto set-up routine is stopped and a RESET of the frequency

inverter is performed.

10 -

Complete Setup, DS0

The auto set-up routine is performed in data set 0 and the param-

eter values are stored in all of the four data sets identically (rec-

The parameter values of the auto set-up are stored in data set 1.

The parameter values of the auto set-up are stored in data set 2.

The parameter values of the auto set-up are stored in data set 3.

The parameter values of the auto set-up are stored in data set 4.

20 -

Plaus.-Check Machine

Data, DS0

The auto set-up routine checks the rated motor parameters in the

four data sets (plausibility check).

108

Operating Instructions

Agile

06/2013 Set-up via the Communication Interface

Loading...

Loading...