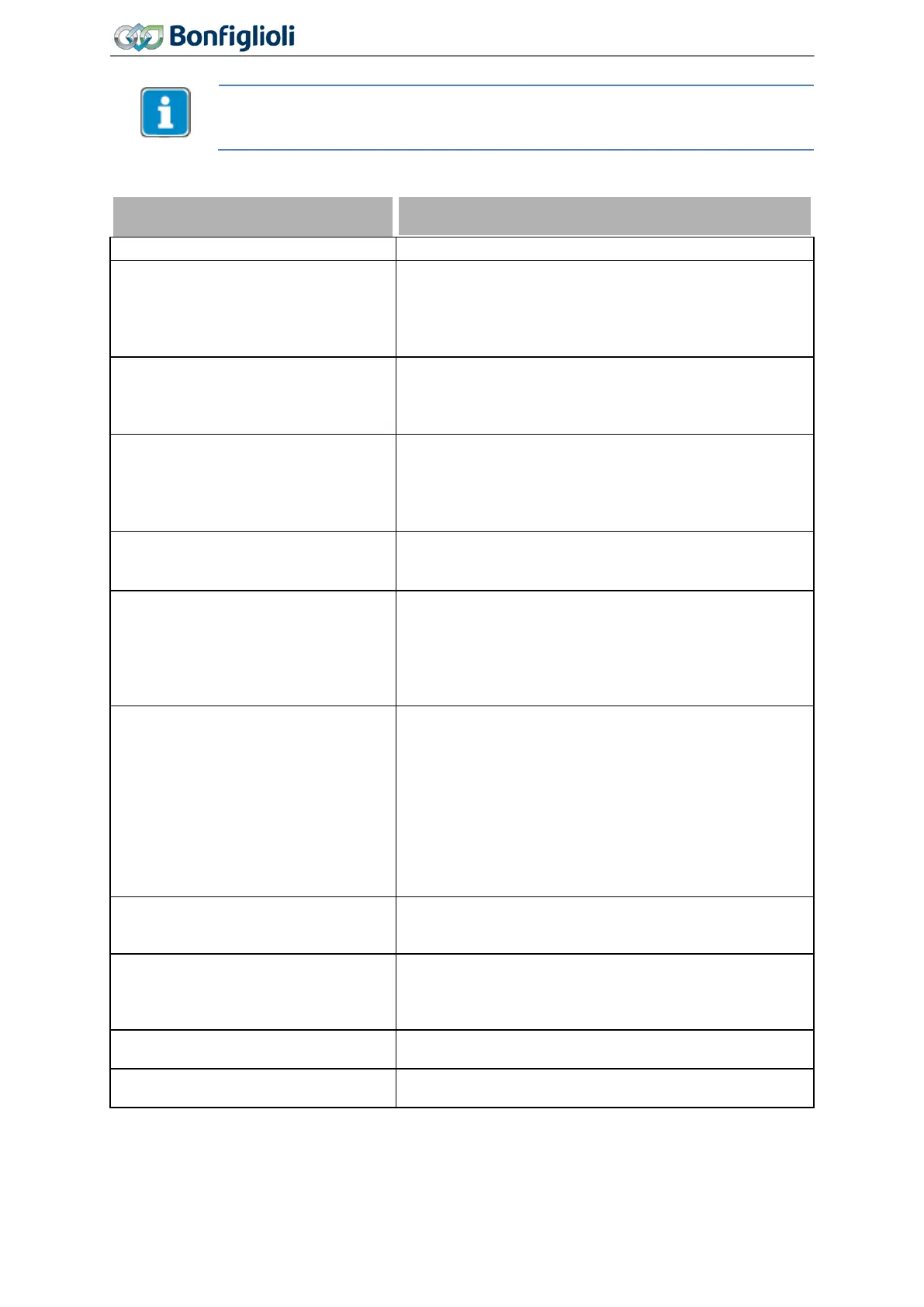

Parameter descriptions

If the same setting is selected for parameter Reference Percentage Source 1 476 and

Reference Percentage Source 2

494

, the reference value is not doubled. In this case

the reference value is the single

value of the selected reference value source.

Selection of source for reference value:

Reference Percentage Source 1 476

Reference Percentage Source 2 494

1 -

Analog Value MFI1A

Multifunction input 1 is the reference value source (termi-

nal X12.3). Via Operation mode MFI1 452, the input must

be set up as an analog input (voltage or current). Factory

setting for

Reference percentage source 1 476.

See chapter 7.6.1 "Multifunction input MFI1".

2 -

Analog Value MFI2A

Multifunction input 2 is the reference value source (termi-

nal X12.4). Via Operation mode MFI2 562, the input must

be set up as an analog input (voltage or current).

See chapter 7.6.2 "Multifunction input MFI2".

3 -

Fixed Percentage

The selected fixed percentage is the reference value

source. The fixed percentage of the current data set is

selected via

Fixed percentage value changeover 1 75 and

Fixed percentage value changeover 2 76.

See chapter 7.5.2 "Fixed percentages".

4 -

Motorpot. via Digital Inputs

Reference value source is the function Percentage motor-

poti up 72 and Percentage motorpoti down 73.

See chapter

7.5.3 "Motor potentiometer".

5 -

Keypad-Motorpot.

The operator panel is the reference value source, with

keys ▲ for increasing the percentage and ▼ for reducing

the percentage. Factory setting for

Reference percentage

source 2

494.

See chapter 7.5.3.4.2 "Control via reference percentage

10 -

Repetition Percentage Value

Digital input IN2D (terminal X11.5) which is set as PWM

input or the pulse train input are used as the reference

value source.

PWM input: For parameter Operation mode IN2D 496,

select setting "10 - PWM input 0% – 100%" or "11 - PWM

input -100% – 100%".

Pulse train input: For parameter

Operation mode IN2D

496, select setting "30 - pulse train".

See chapter 7.6.7 "

Input PWM/repetition frequency/pulse

20 -

Fieldbus Percentage Value

The reference value is transmitted via a bus system. The

field bus must write the value in format xxx.xx % into pa-

rameter 524, from which the value is then used.

95 -

Obj 0x6071 Target Torque

The torque reference value for torque control is transmit-

ted via CANopen bus system. The signal source contains

the value of CANopen object 0x6071. Refer to the commu-

2521 -

PLC Output Percentage 1

Percentage output 1 of a PLC-function is the reference

value source. See application manual "PLC".

2522 -

PLC Output Percentage 2

Percentage output 2 of a PLC-function is the reference

value source. See application manual "PLC".

The reference percentage channel can be used in all configurations (parameter

Configuration 30).

152

Operating Instructions

Agile

06/2013 Reference Values

Loading...

Loading...