Parameter descriptions

Parameter Operation Mode 571 = 1 or 11, (101 or 111).

In multiple motor operation, it is assumed that each data set is assigned to a corresponding motor.

For this, one motor and one motor circuit breaker are assigned to each data set. In this operation

mode, the rated values of the active data set are monitored. The current output current of the fre-

quency inverter is only taken into account in the motor circuit breaker activated by the data set. In

the motor circuit breakers of the other data sets, zero current is expected, with the result that the

thermal decay functions are taken into account. In combination with the data set changeover, the

function of the motor circuit breakers is similar to that of motors connected alternately to the mains

with their own circuit breakers.

Parameter Operation Mode 571 = 2 or 22, (102 or 122).

The internal state of the motor circuit breaker is stored reset stable. These settings are to be used for

short-time time mains shut downs. This way the motor protection is considered correctly also in appli-

cations where a short mains power off or a shutdown orccurs.

Reset stable

Parameter Operation Mode 571 = 101, 102, 111 or 122.

The internal state of the motor protection switch is latched reset stable. These be used when regularly

short mains interruptions occur. This way the motor protection correctly for short mains failures or

short shut downs of the application.

In settings 101, 102, 111 and 112 of

Operation Mode 571 the same values should be set

in all data sets.

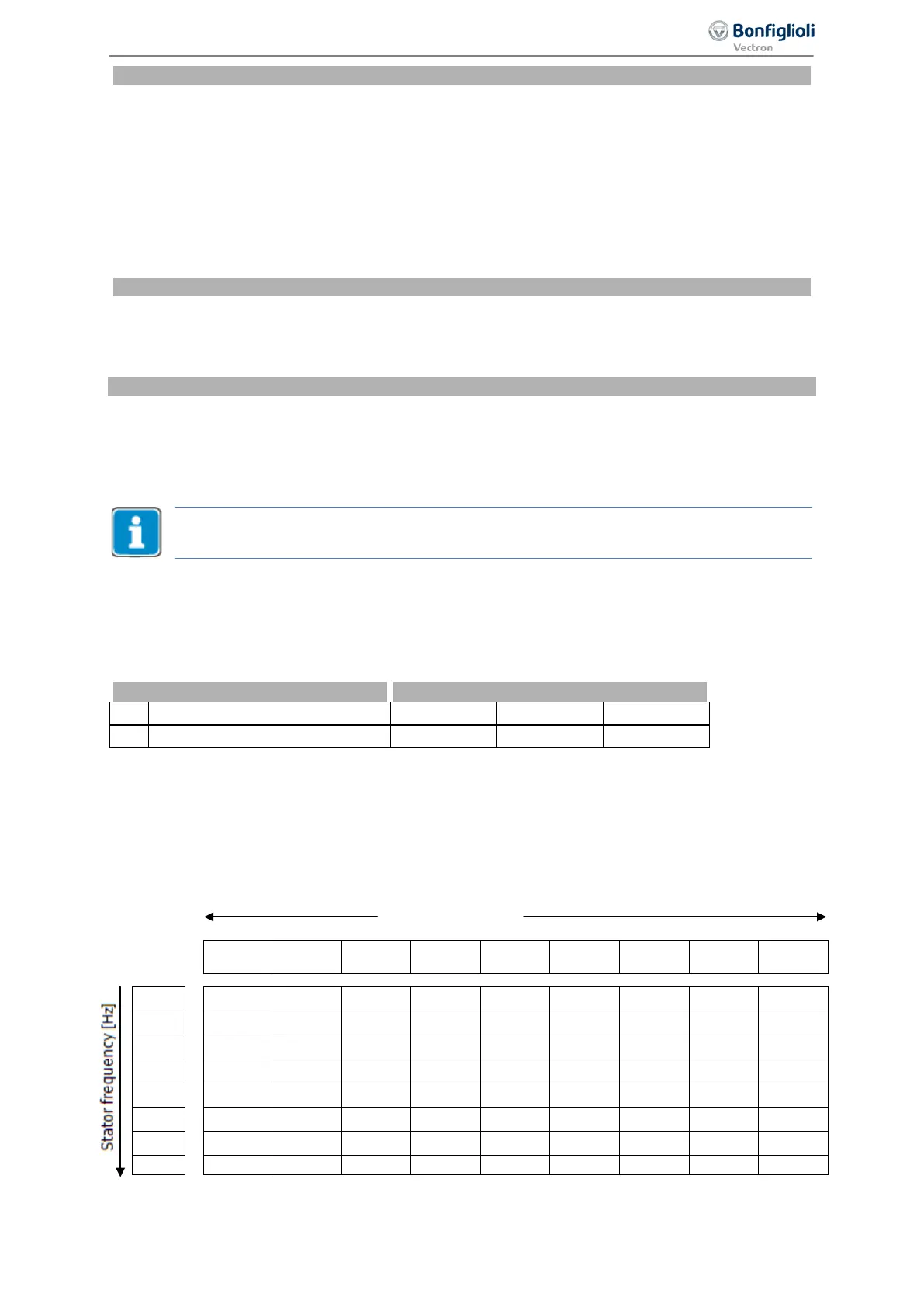

572 Frequency Limit

The motor protection, especially of self-ventilated motors is improved by an adjustable frequency

limit. Percentage reference is the rated frequency.

572 Frequency Limit 0% 300% 0%

In calculation the tripping time the measured output current in operating points below the frequency

limit is evaluated by a factor between 1 and 2. The determination of this factor is a function of the sta-

tor frequency. The increased thermal load of self-ventilated motors in the lower speed range is there-

fore considered.

The table shows in extracts factors for motor rated frequency 50Hz.

Frequency limit 572

247

Special functions 06/2013 Operating Instructions

Agile

Loading...

Loading...