116/188 Commissioning

Bosch Rexroth AG, MIT: ActiveMover, 3 842 564 874/2021-04

8.3 Residual risks

Table 6: Residual risks

Life stage

1

)

, location Situation Hazard Action

1 2

9

21

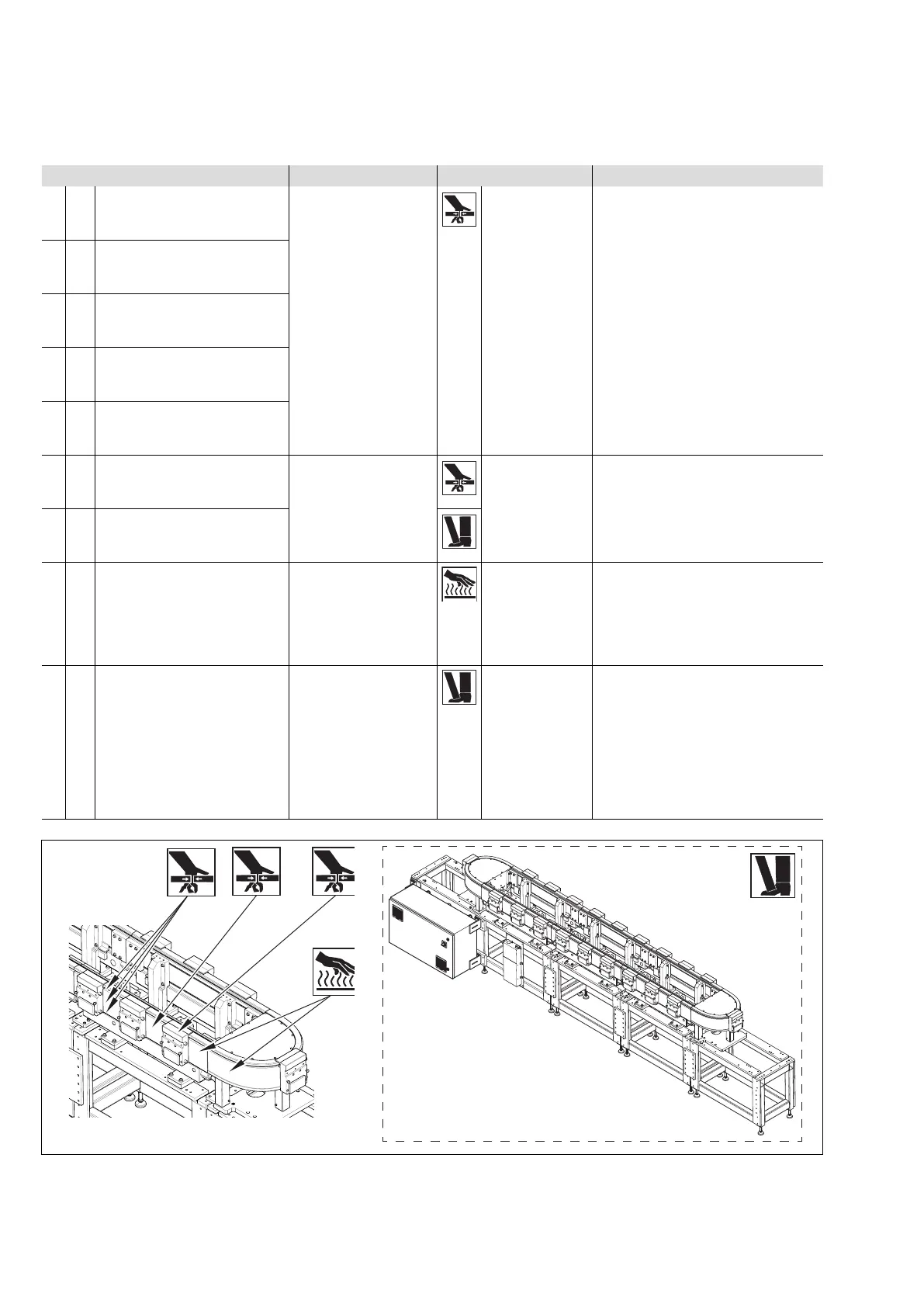

Between WT and section/curve

module

Crushing and shearing

of body parts

Crushing/

shearing

Keep hands out of the running system.

Provide access locks in work areas

e.g. by separating protective equipment

in accordance with DIN ISO EN 14120

with guard-locking (PLr = d in

accordance with DIN EN ISO 13849).

2 2

9

21

Between WT and upper V-rail

3 2

9

21

Between WT castors and

slide rail

4 2

9

21

Between WT tipping prevention

block (discharger brush) and

upper V-rail

5 2

9

21

Between WT and WT

6 2

9

21

WT, collision with body part Crushing and shearing

of body parts, knocks

Crushing/

shearing/knocks

Keep hands out of the running system.

Provide access locks in work areas

e.g. by separating protective equipment

in accordance with DIN ISO EN 14120

with guard-locking (PLr = d in

accordance with DIN EN ISO 13849).

7 2

9

21

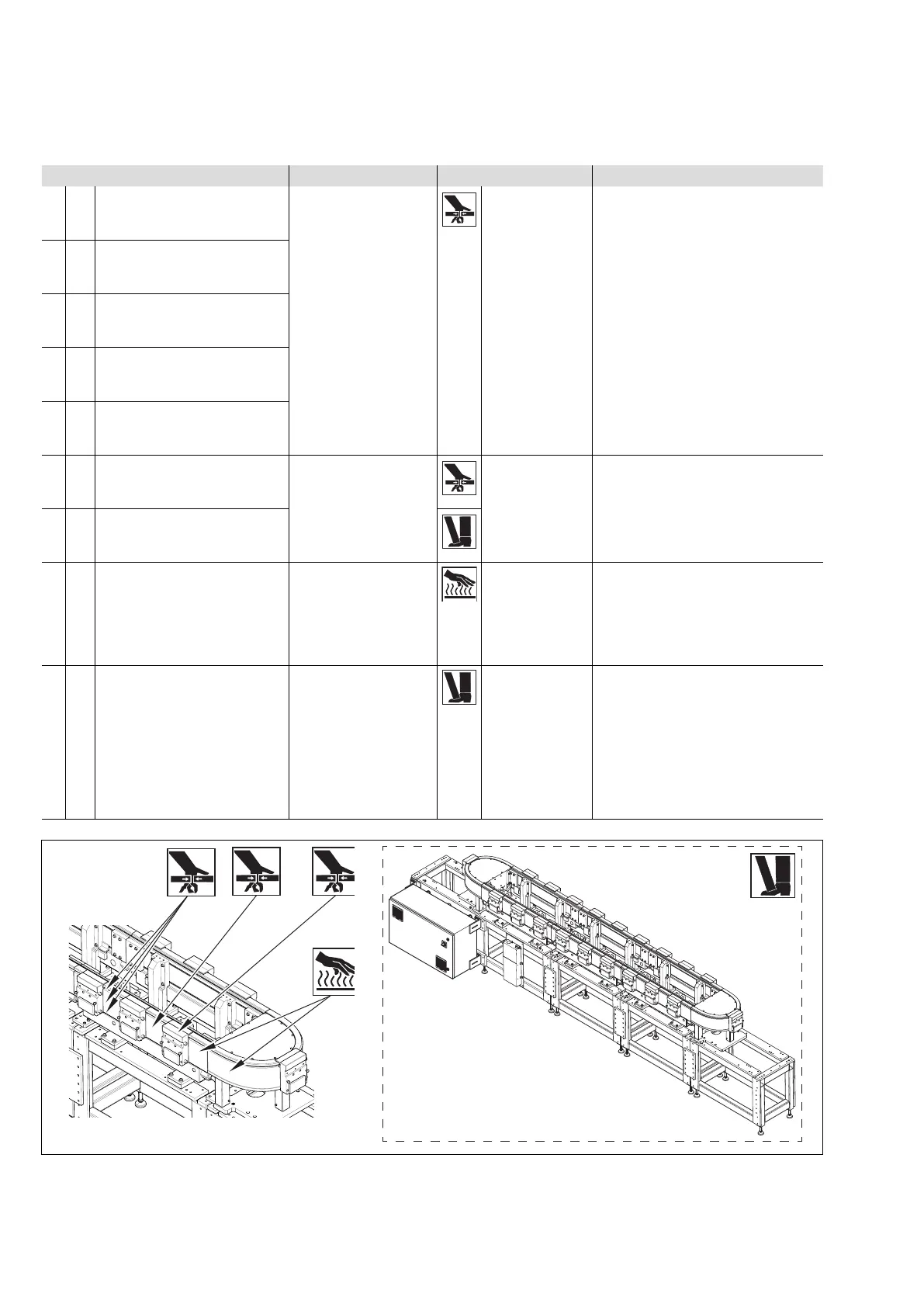

WT, spontaneous ejection or

falling

8 2

9

21

- Surface of section/curve

module

- Electronic components in

the entire system

Touching hot surfaces

above 65 °C

Burning

Keep hands out of the running system.

Provide access locks in work areas

e.g. by separating protective equipment

in accordance with DIN ISO EN 14120

with guard-locking (PLr = d in

accordance with DIN EN ISO 13849).

9 2

9

21

In the entire area of the system Entrapment of body

parts caused by falling

parts

Crushing

Observe maximum loading

specifi cations and process force.

See chapter 16 Technical data.

Keep hands out of the running system.

Provide access locks in work areas

e.g. by separating protective equipment

in accordance with DIN ISO EN 14120

with guard-locking (PLr = d in

accordance with DIN EN ISO 13849).

1) Life stages of the machine according to DIN EN ISO 12100 Sect. 5.4 a /b (No. 1 -27), Sect. 5.4 a (see page 117)

5 6, 7

557 186-198

1, 2, 3, 4

8

9

557 186-199

Loading...

Loading...