Programming and operating manual Model 1001 DFB

102 FICEP S.p.A.

CHAPTER 10: MAINTENANCE AND TROUBLE SHOOTING

Signalling and messages

The CNCC: software is enabled to recognize some events giving out clearly messages for the operator;

depending on seriousness and danger of the situation, the CNC can “decide” to halt its working. Each

message is marked by a numerical code (error code) possibly followed by a second numerical code

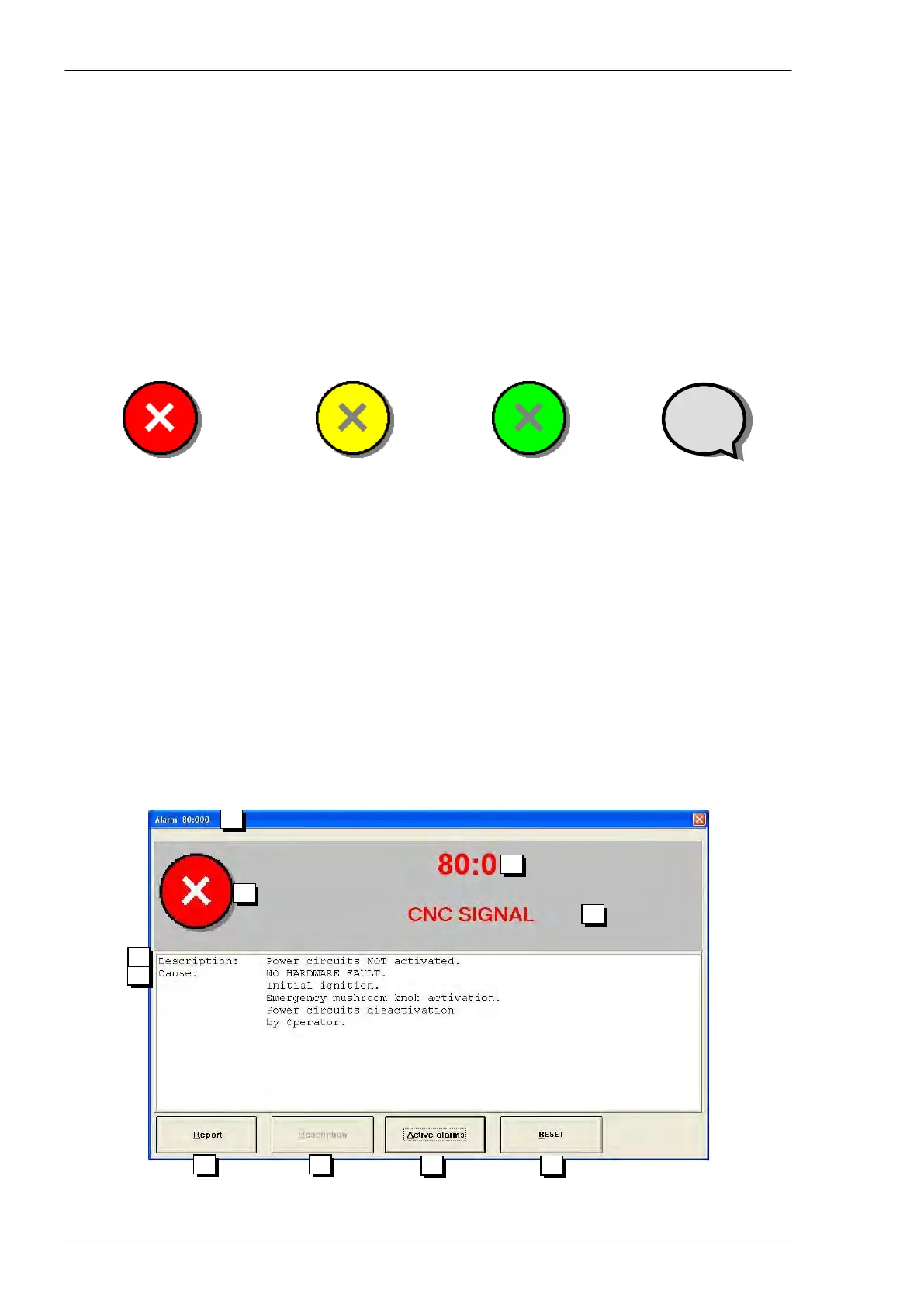

(cause code); the two codes are separated by a “:” they appear in four different colours:

Information message

(Yellow)

An alarm shuts off the pow-

er to auxiliary circuits of the

machine leaving connected

only the CNC The action is

the same of the emergency

push-button.

A red message normally

occurs when something

dangerous happens, like a

collision, a damaged driver,

the emergency push-button

activated, etc…

F.I. “Encoder signals alarm

axis n”

A message informs the

operator about a par-

ticular condition of the

line; the CNC software

stops the actual action

but doesn’t shut off the

power.

F.I. “Enable for axis n

movement not

present”

A wait message in-

forms that the CNC

software asks for time

to end some opera-

tions, during which it

can’t accept orders

from operator.

F.I. “Waiting for end

of phase n. 2 of

zero cycle”

An error message

normally occurs when

a particular action or a

set up by operator is

wrong.

F.I. “Selection not

possible”

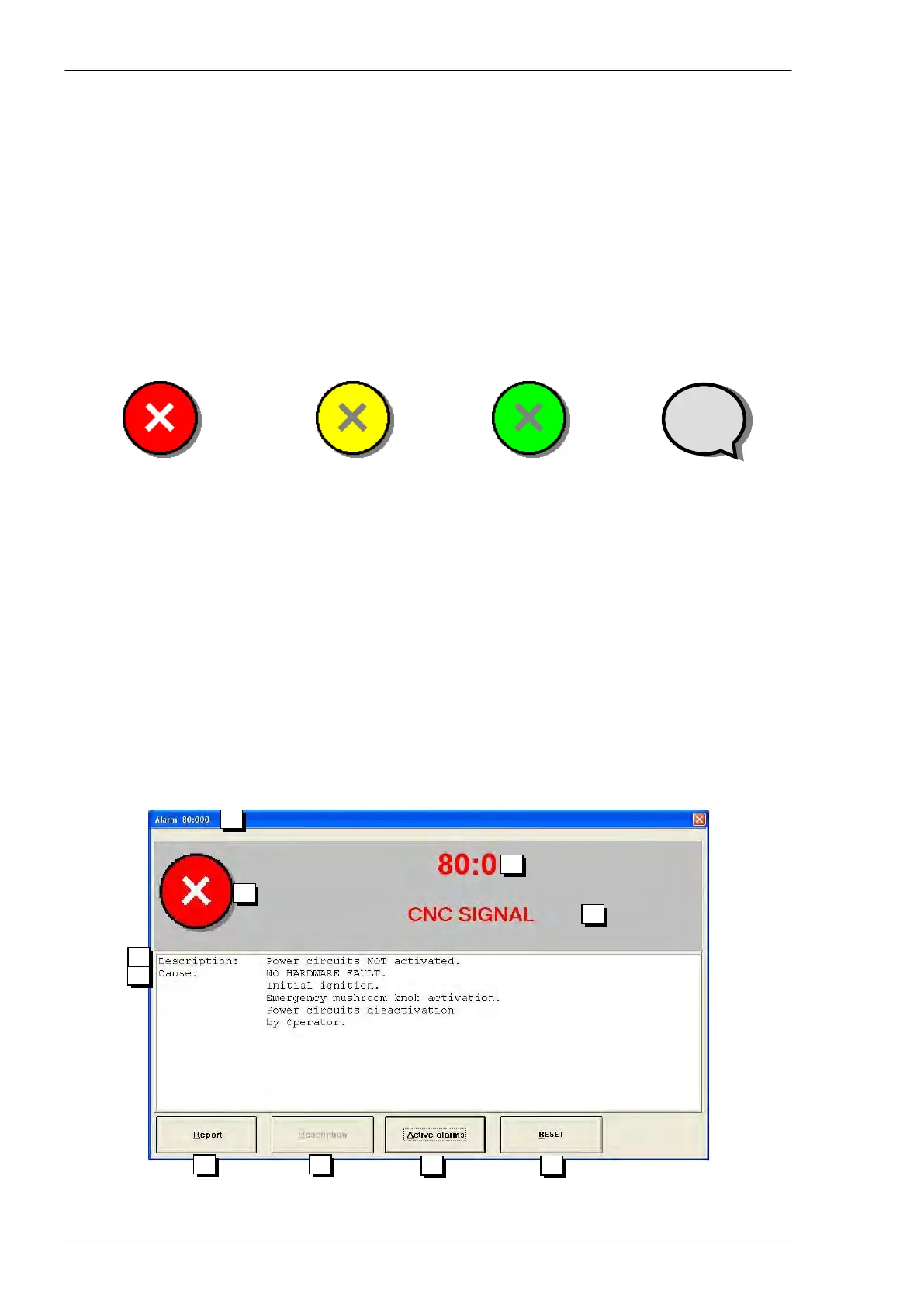

The window of a message is like in the following picture:

Loading...

Loading...