Model 1001 DFB Programming and operating manual

FICEP S.p.A. 67

ATTENTION: This function is executable only if the drilling tool is long enough with refer-

ence to the transversal dimensions of the profile.

The G74 and G75 special functions simply activate and deactivate, respectively, the mirroring mode with

reference to X coordinate..

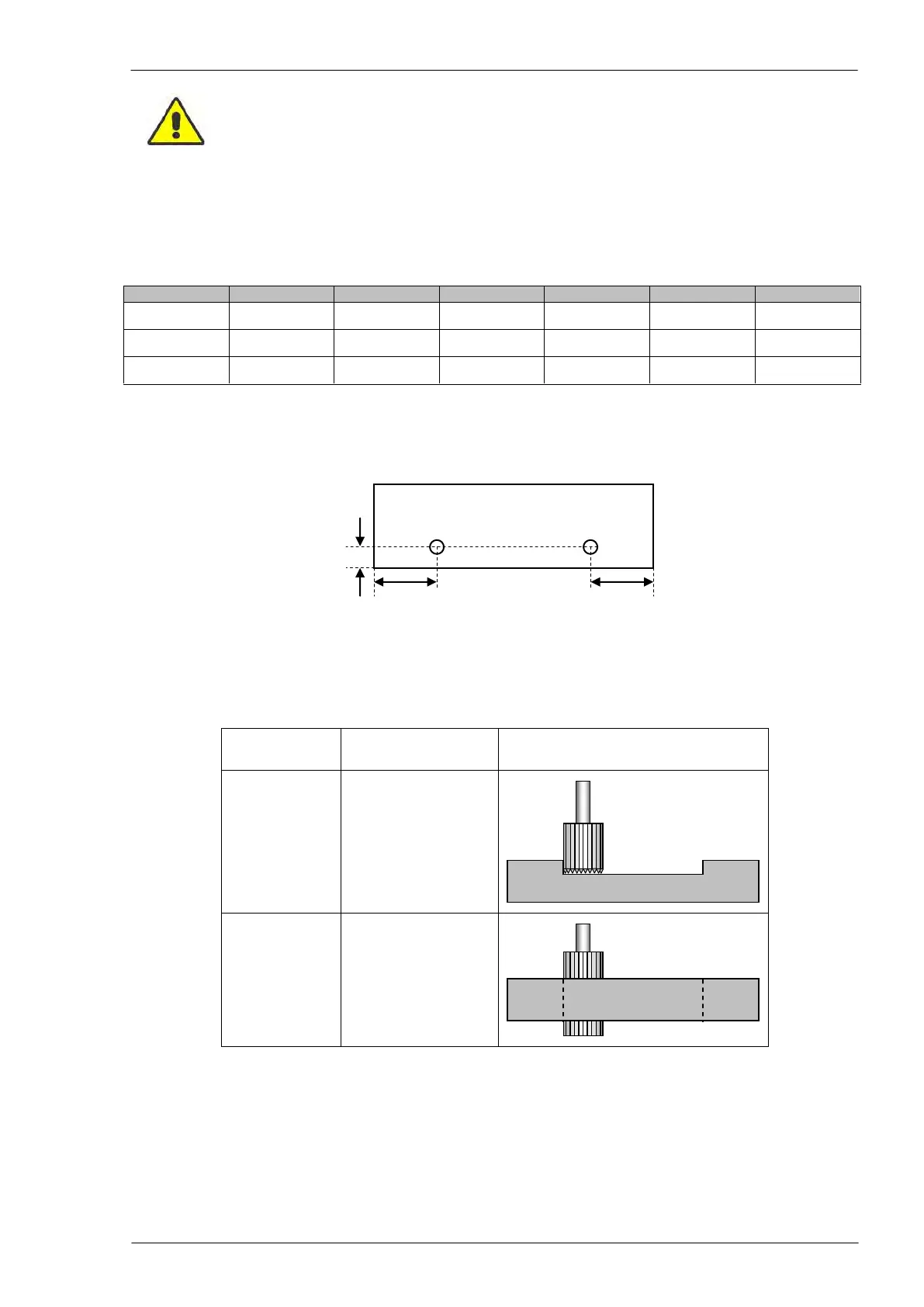

In the next program the CNC performs two holes with just a single drilling instruction.

N.B. The values of X and Y coordinates are not significant

In the following picture the practical output of the previous program.

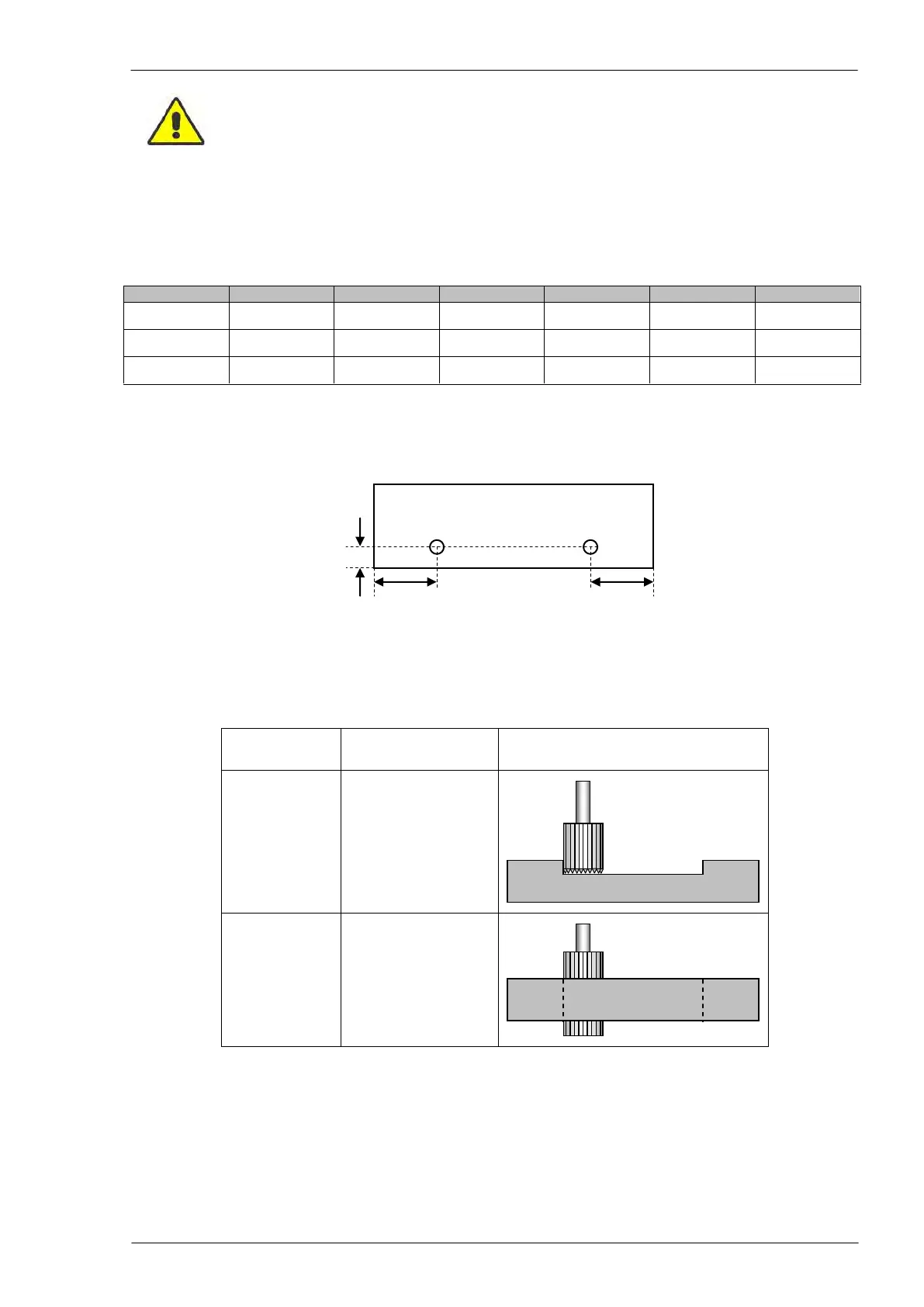

Milling operations

The pocketing operation consists in slow approach to the material surface for first material removal and in

further following passes to get the programmed depth.

The milling operation, instead, consists in fast approach until a predetermined coordinate beyond the ma-

terial surface and in the next cross movement to remove material at working speed. Milling operations can

be performed only starting from a hole with, at least, same diameter of the milling tool.

Both operations are programmed by two instructions: “LEAD” which defines the coordinates of starting

point and the type of operation (POCKET or MILL) and “CUT” which defines point-to-point the tool way.

Loading...

Loading...