Programming and operating manual Model 1001 DFB

22 FICEP S.p.A.

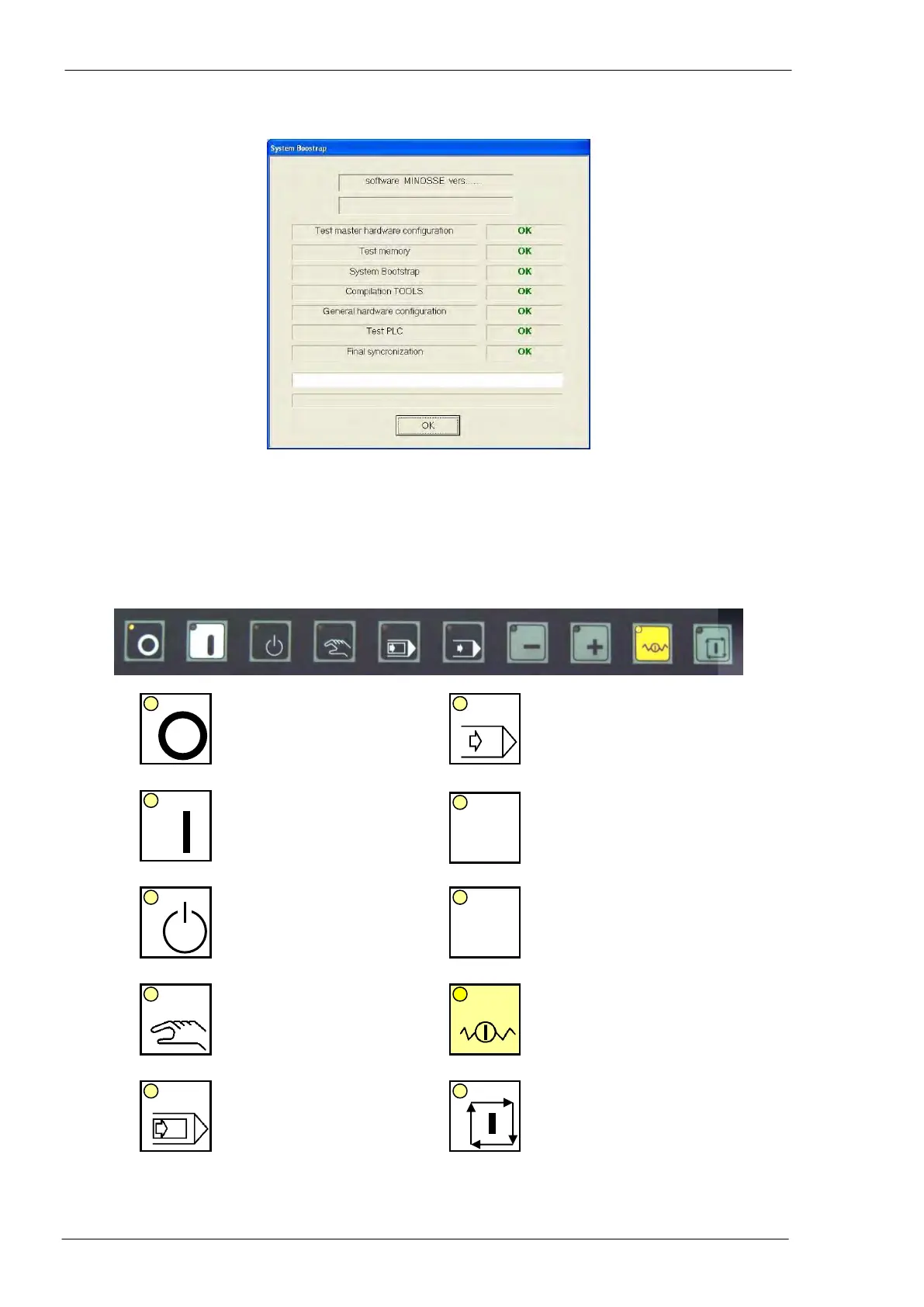

All the items have to result as “OK”; if any “NOT OK” answer appears, the CNC has hardware or software

problems.

End the procedure pressing the “OK” push-button.

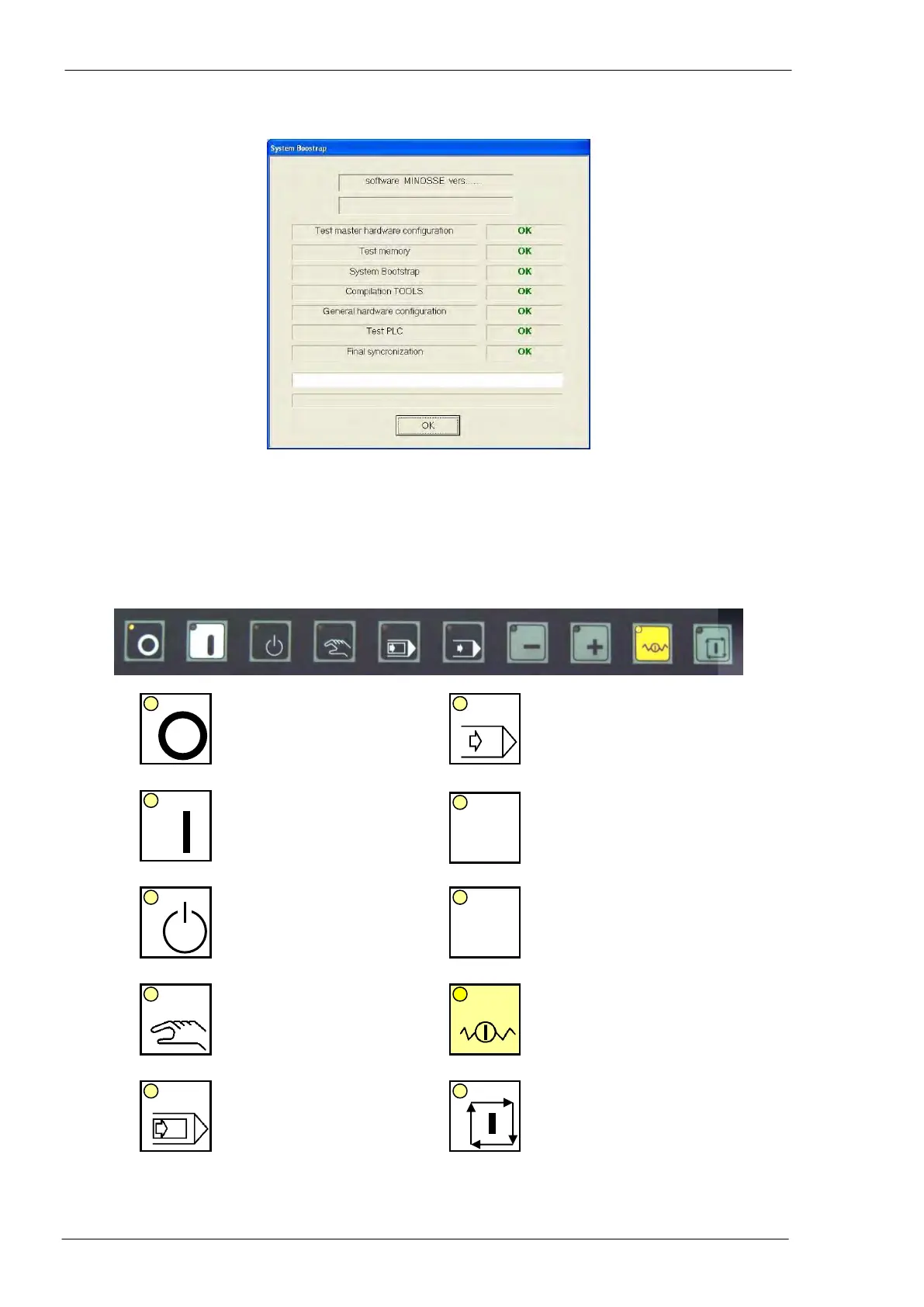

The main push-button panel

Switching OFF of the line

auxiliary circuits (ex. the

oil pump)

Automatic mode, continu-

ous execution

Switching ON of the line

auxiliary circuits (ex. the

oil pump)

JOG -: manual movement

of the selected axis to-

wards negative direction

(decreasing coordinates)

Stand-by mode: axes are

not qualified. Program-

ming and setup opera-

tions are enabled

JOG +: manual movement

of the selected axis to-

wards positive direction

(increasing coordinates)

Manual mode: it enables

the axes manual control

by means of the push-

buttons “+” and “-“ when

the “Jog” window is open

Hold cycle: all the axes

stop and keep the actual

position

Automatic mode, single

execution (step by step)

Automatic cycle start: the

selected cycle is started

(part process, zero cycle,

etc…)

Loading...

Loading...