Programming and operating manual Model 1001 DFB

90 FICEP S.p.A.

By this mark the CNC can restart the program, after a pause, exactly

from the first instruction not executed yet (first red smile)

Lxxx line number

X… Y… positioning coordinates used in the line

Oper. description of operation type and related tool

Measuring unit used in the execution program

Control for manual jog for all axes

Setup tables (fitted tools)

Operator parameters to adjust some basic operations (drilling, pointing, marking,

cutting; see page n. 96)

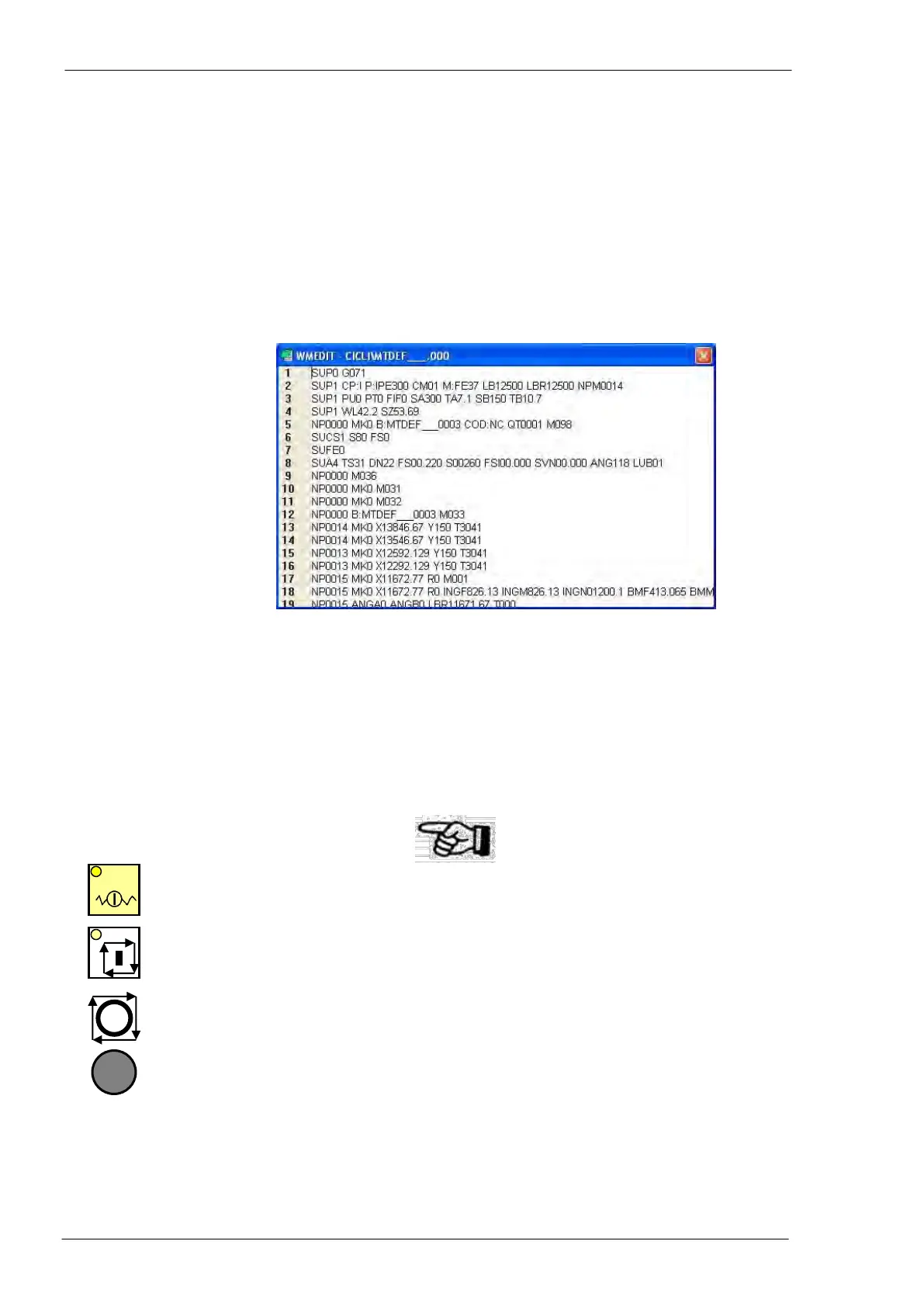

Display of canonic program; pressing the push-button “Open” in the next choice win-

dow, the operator gets a new text window with whole coded canonic program. The

content of this window is read-only (no modification is possible).

Tools tables (general tools database of the CNC - see page n. 39)

Pressing this push-button the operator can choose to execute among a new piece

program, a new nesting program or a cycle.

Cycles are special test programs stored in the CNC memory in FICEP factory

Soft-keys for machine tuning and direct control of some devices (see page n. 31 and

following)

Operator controls during automatic execution

The operator can press this push-button at any time to tempo-

rary halt the program execution.

The operator can use this push-button to start the program or to

restart it, after a pause, from first not executed line.

The operator can press this push-button at any time to get im-

mediate stop of the execution and all tools in safety position (far

from material in “home” position) without put the line in emer-

gency mode; when the operator presses the “Start Cycle” push-

button the CNC restarts the program execution from first instruc-

tion not executed yet or re-executing the last instruction not end-

ed, depending on the moment the operator has pressed the

push-button.

Note that this push-button is in the control and safety push-

button panel and not in the main push-button panel.

Loading...

Loading...