MACHINE SET-UP

1001 DFB

Drilling & Sawing Line

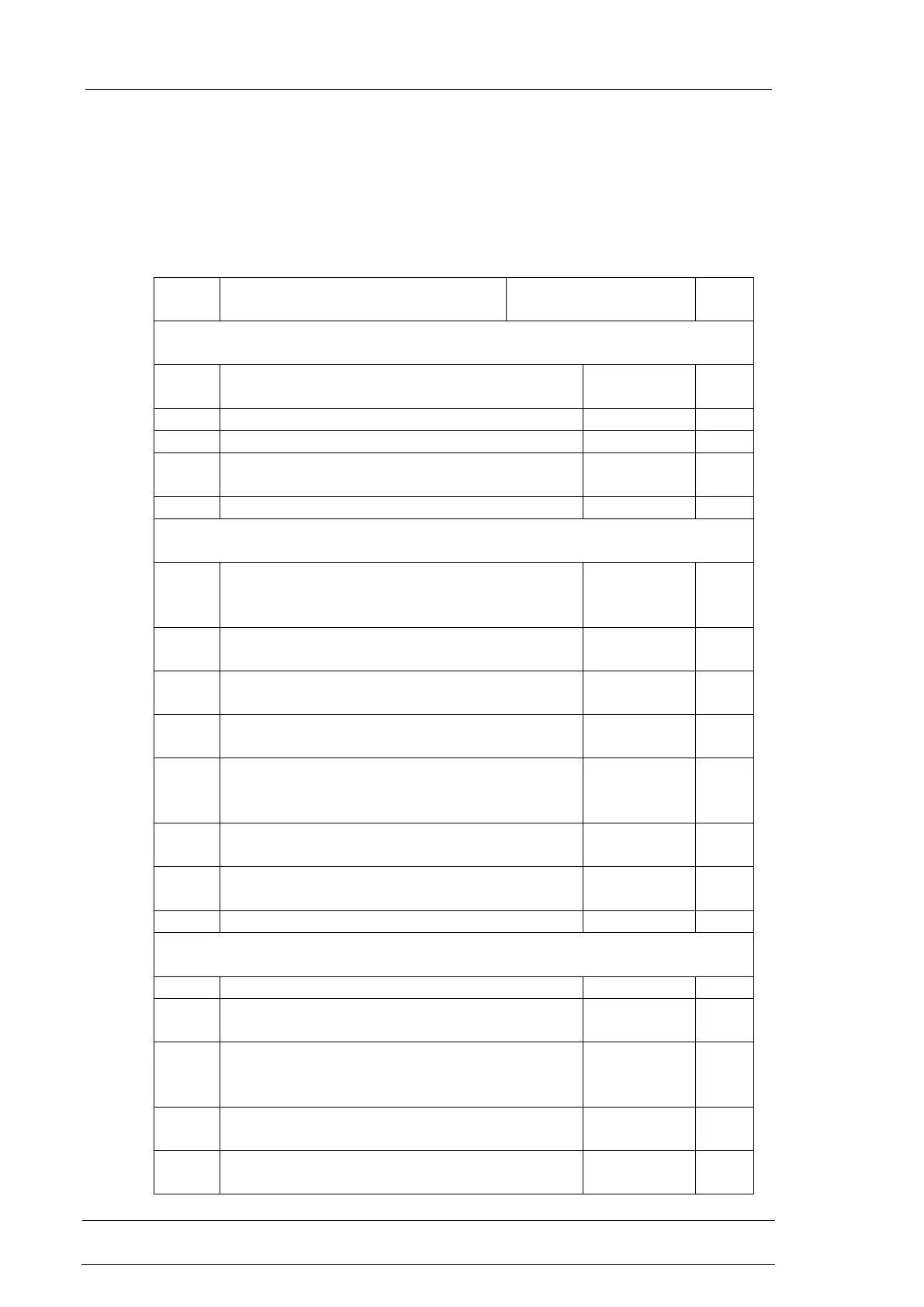

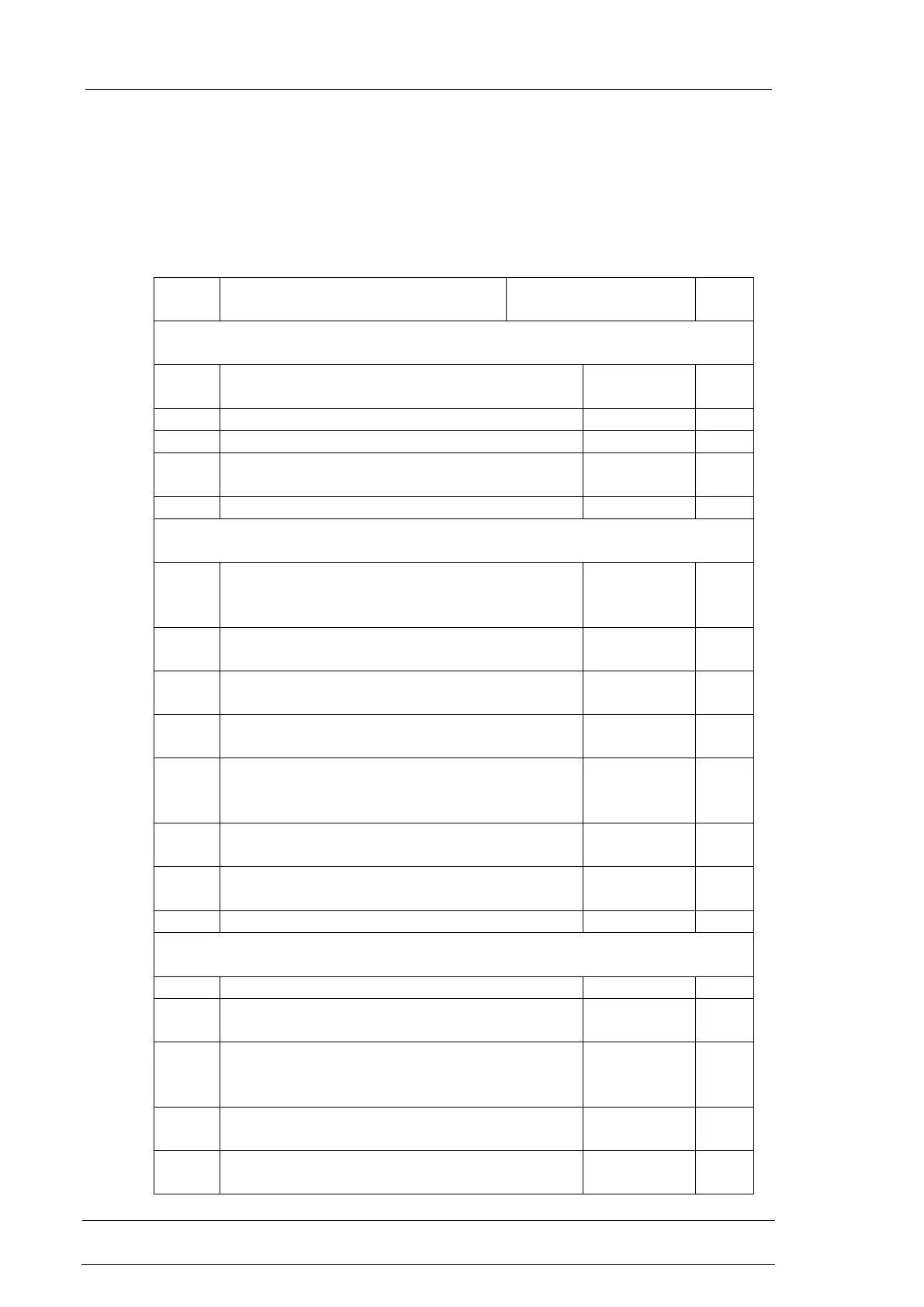

4.7 Recapitulation table of routine maintenance interventions

In the following table are resumed the routine maintenance interventions to

be scheduled on the line. Interventions frequency has been calculated in

working days of system operation.

frequency

(system working days)

calamine removal from chains of loading and

unloading tables

cleaning of sliding guides of carriage

cleaning of: photocells, reflectors, proximity

transducers, limit switches

cleaning of working units area

transmission chains lubrication of loading /

unloading conveyors and infeed/outfeed

rollerways (and topping up if necessary)

check of oil level in loading/unloading tables

reduction gears (and topping up if necessary)

manual lubrication (on appropriate points) of

loading/unloading rollerways

check of oil level in the carriage reduction gear

(and topping up if necessary)

manual lubrication (on appropriate points) of

vices, hold down, rolls on the machine and

guides

manual lubrication (on appropriate points) on

carriage guides

check of oil level in loading/unloading tables

reduction gears (and topping up if necessary)

fluid level check of drills lube cooling system

controls, tightenings, adjustments

check of oil level in the hydraulic power unit

check of lubrication system integrity, grease

arrival points and tightening of the inlet pipes

tightening control of cams, proximity

transducers, limit switches, connectors,

terminals and insulating on electric equipment

control of pipes tightening and check of wear

of flexibles on fluid systems

driving belts control of positioning and

forward axes of the working unit

Loading...

Loading...