Programming and operating manual Model 1001 DFB

52 FICEP S.p.A.

CHAPTER 6: PROGRAMMING

Preliminary remarks

“Programming” means translate the drawing of the piece to perform into CNC executive instructions.

A program can be inserted into the CNC by:

- importing files from an external PC, in this case the program could be generated with other pro-

grams like, for instance, Winsteel

- direct editing on the touch screen of CNC; in this case display the “Programming” screen page

Anyway, these agreements are valid:

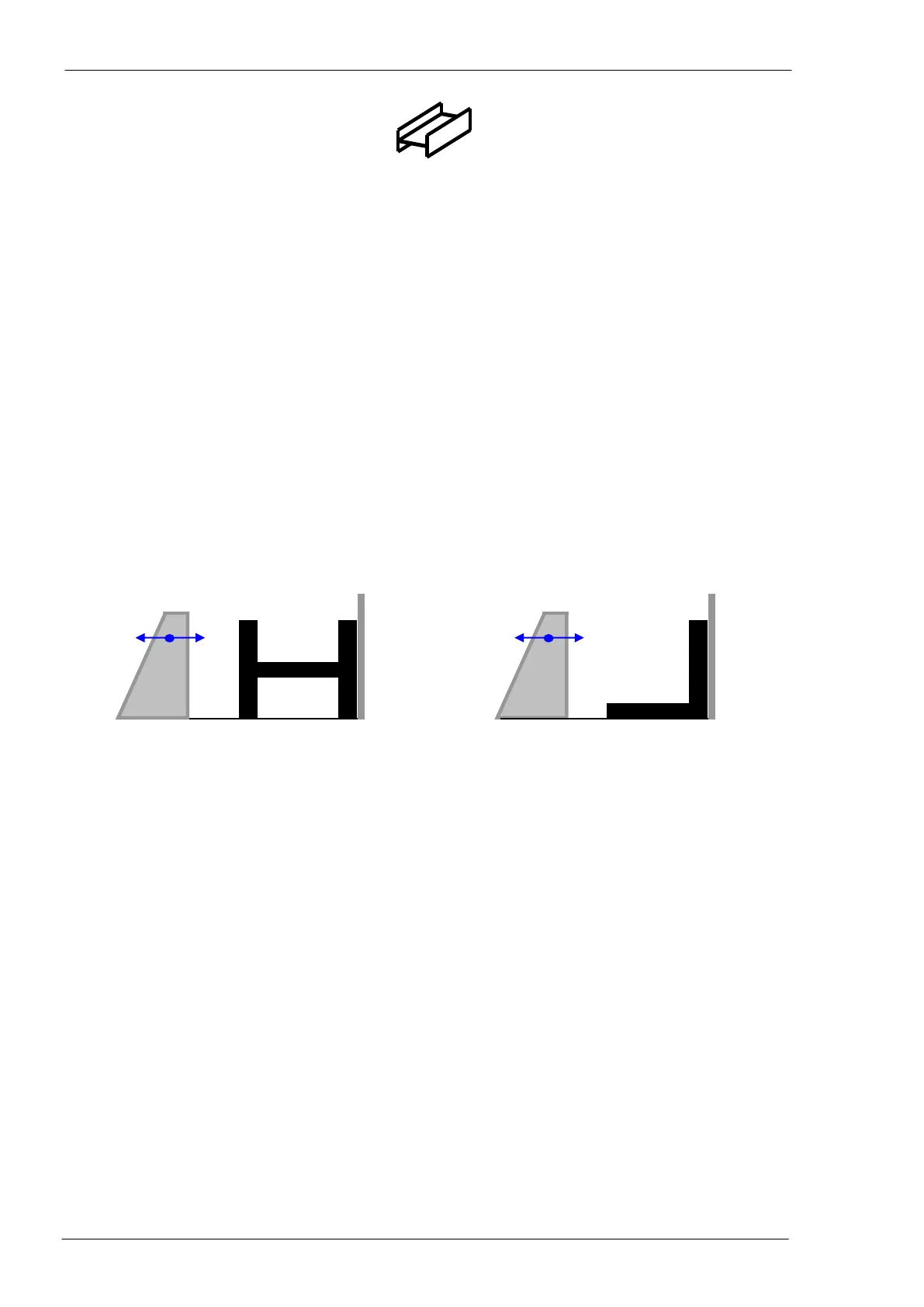

all profiles different from “L”

side “A”: profile side toward datum line; from here, we shall call it “flange A”

side “B”: profile side toward mobile vice reference side; from here, we shall call it “flange B”

side “C”: horizontal upper side of the profile; from here, we shall call it “upper web”

side ”D”: horizontal lower side of the profile; from here, we shall call it “lower web”

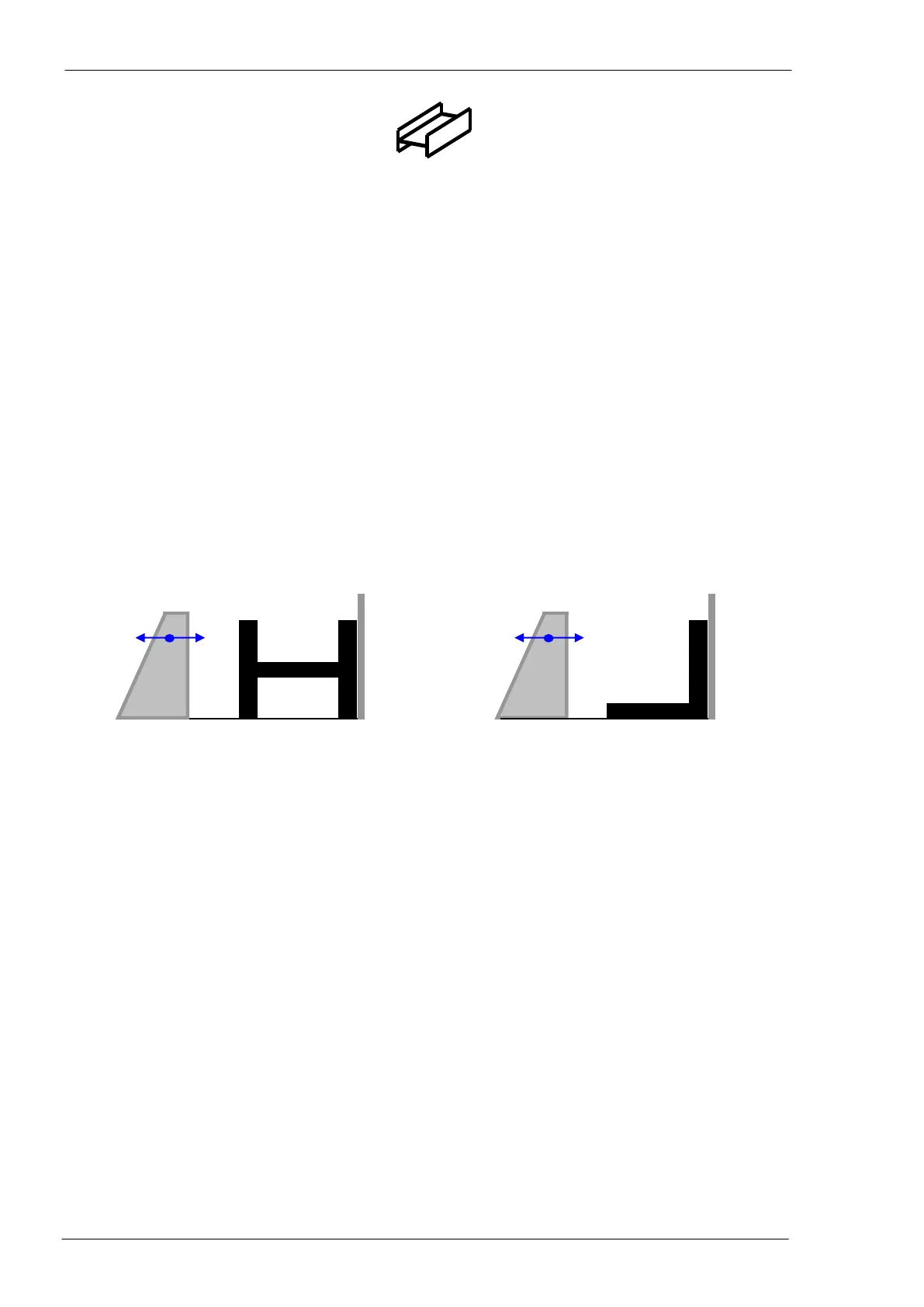

“L” profiles

side “A”: vertical profile side toward the datum line; from here, we shall call it “flange A”

side “B”: horizontal profile side on the working plane; from here, we shall call it “flange B”

NOTE: To program, the activation of auxiliary circuits (oil pump, etc…) is not required.

Terminology

instructions list to program a piece into the CNC software

list of all pieces programmed in the CNC software (available in the program-

ming window)

row material to be cut to get the programmed pieces

to arrange the pieces into a bar

list of all the nested bars

executing program of the CNC generated starting from

- piece program to execute a single piece

- bars list to execute a nested bar

Loading...

Loading...