2. Replacement and adjustment of parts

26820

9/10

26820

Zigzag adjustment

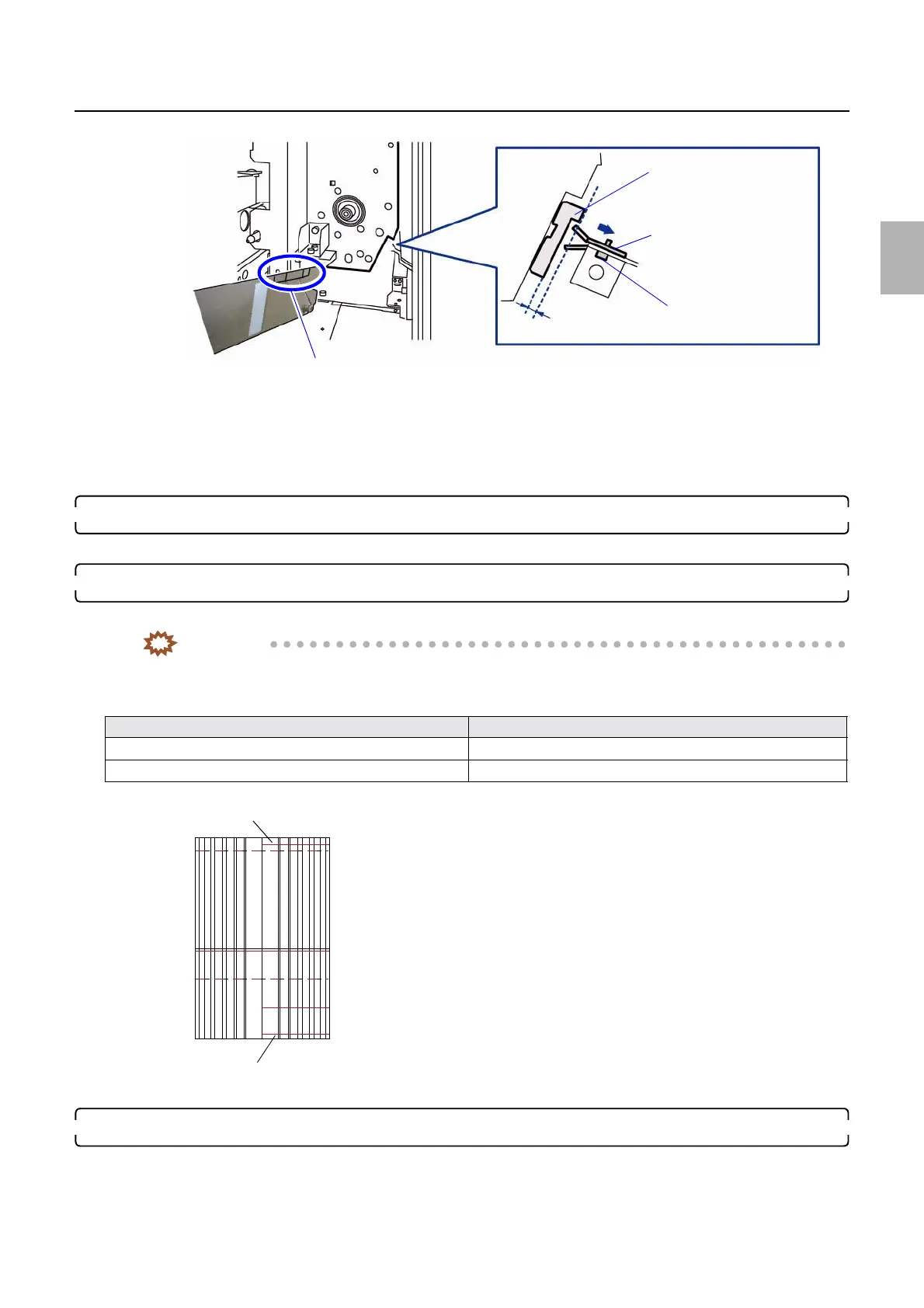

(8) After adjusting the paper guide position, confirm if the manual cutter smoothly moves in and out.

(9) Reconfirm the paper center of paper supply unit A2.

• See ☞4 Confirming the paper center of paper supply unit A2.

8. Reconfirm the paper center of paper supply unit A2.

☞4 Confirming the paper center of paper supply unit A2

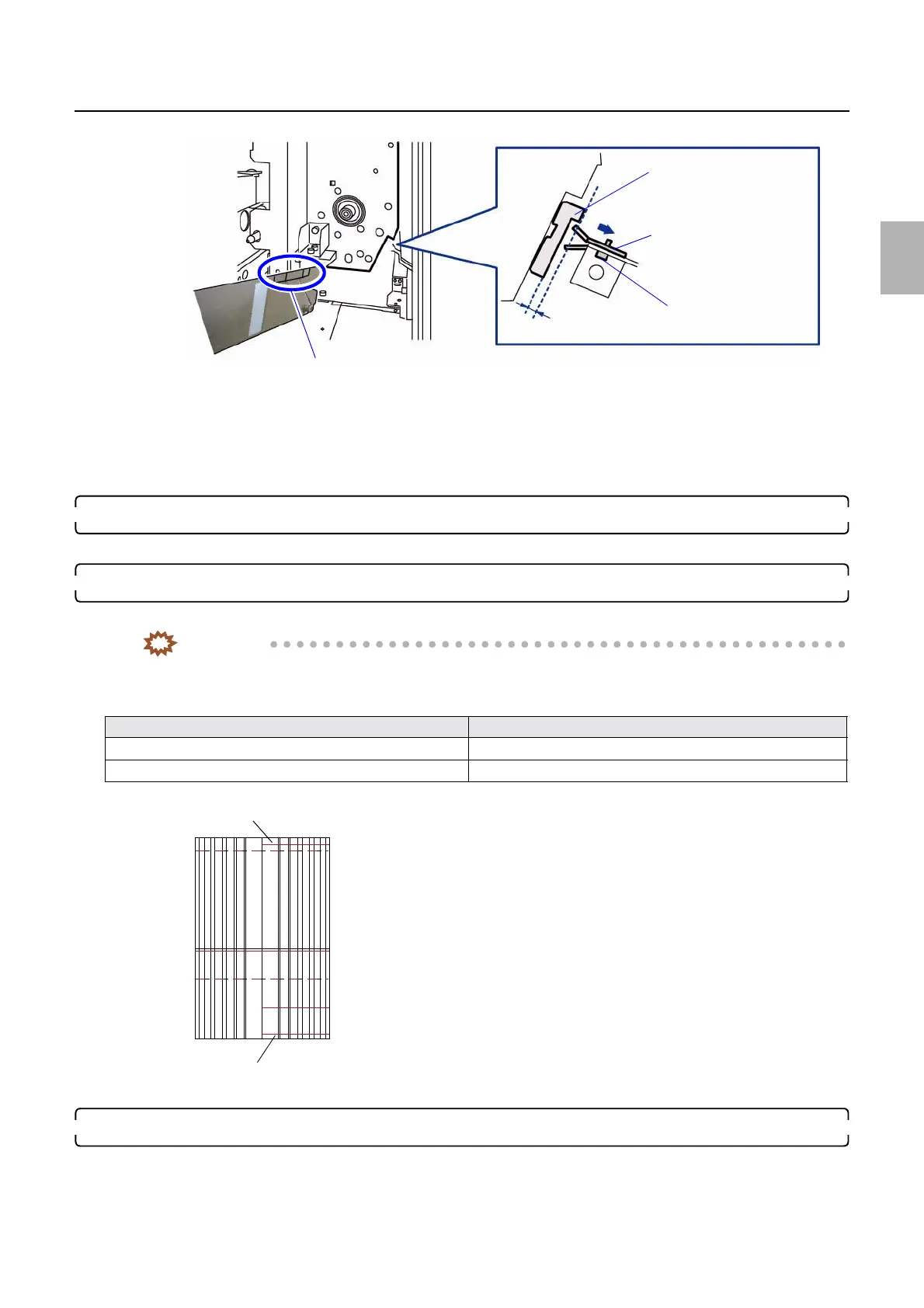

9. Perform Arm Unit 1 Zigzagging Correction.

☞36060

IMPORTANT

• Make test prints via Test Print Confirmation 1/2 to check the zigzagging amounts (A - C) of two prints are

within the tolerance level in the following table.

If they are within the tolerance level, the adjustment is not necessary.

10. Paper Guide Width Correction (for each Paper Width)

This operation is necessary for all paper widths and surfaces used for paper magazine A2.

Test print Tolerance range

Test print 1 (457.0 mm) A − C is within ±0.5 mm

Test print 2 (914.0 mm) A − C is within ±1.0 mm

Convex part of the manual cutter

Convex part of the manual cutter

Paper guide inlet plate

1.5 mm

Two adjusting screws

G090249

A

BC

Line A

Line C

G078473

Distributed by: minilablaser.com

Loading...

Loading...