Appendix9 Temperature Correction Function (TC)

A14

Reference

Conductive Properties of Metals and Alloys

Copper Wire Conductivity

The temperature coefficient changes according to temperature and conductivity, so if the temperature coeffi-

cient at 20C is

20

and the temperature coefficient for conductivity C at t C is

ct

,

ct

is determined as fol-

lows near ambient temperature.

For example, the temperature coefficient of international standard annealed copper is 3930 ppm @20C. For

tinned annealed copper wire (with diameter from 0.10 to less than 0.26 mm), the temperature coefficient

20

at 20C is calculated as follows:

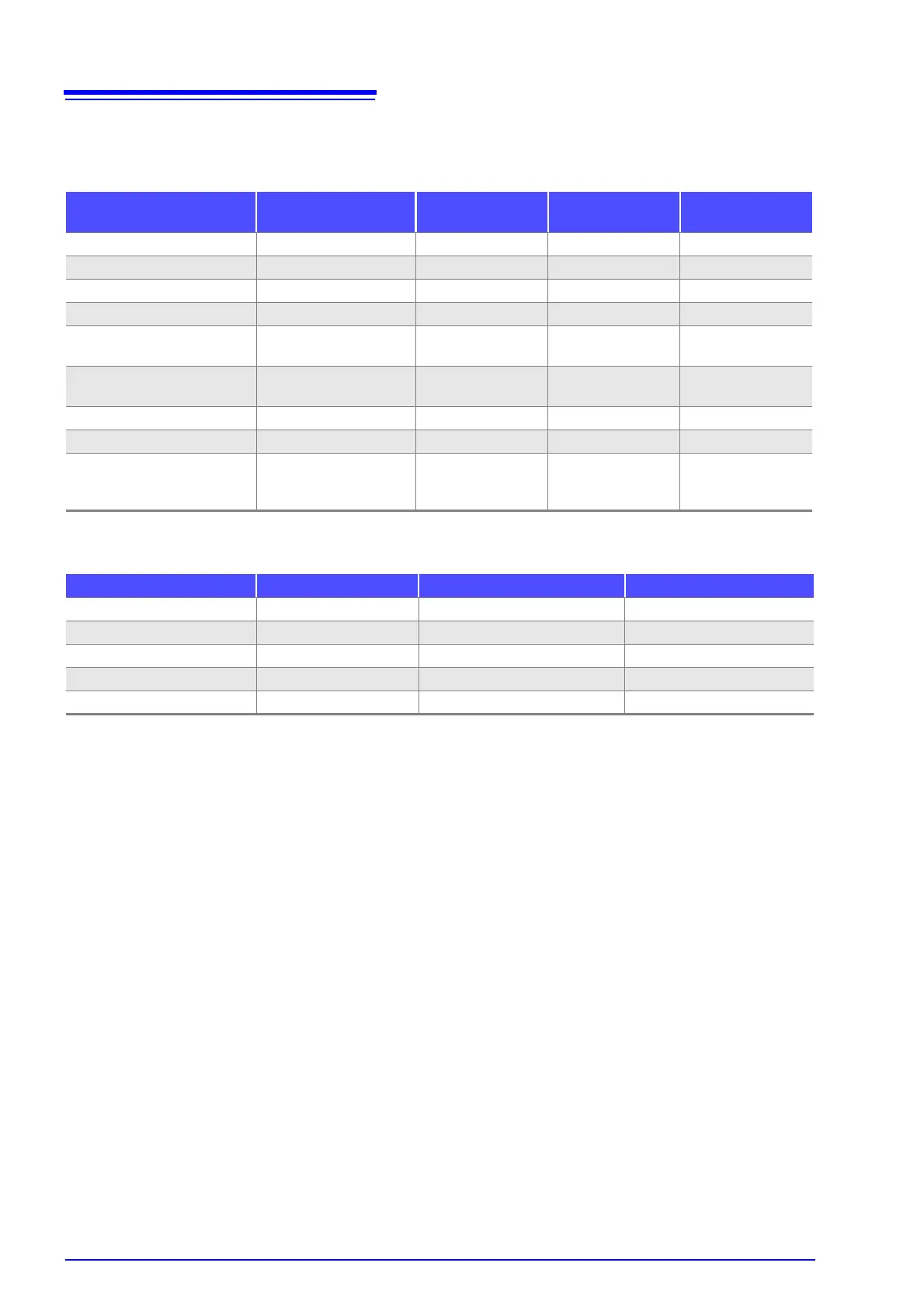

Material Content [%]

Density (x10

3

)

[kg/m

3

]

Conductivity [%]

Temp. Coeff.

(20°C) [ppm]

Annealed copper wire Cu>99.9 8.89 1.00 to 1.02 3810 to 3970

Hard-drawn copper wire Cu>99.9 8.89 0.96 to 0.98 3770 to 3850

Cadmium copper wire Cd 0.7 to 1.2 8.94 0.85 to 0.88 3340 to 3460

Silver copper Ag 0.03 to 0.1 8.89 0.96 to 0.98 3930

Chrome copper Cr 0.4 to 0.8 8.89

0.40 to 0.50

0.80 to 0.85

2000

3000

Carlson alloy wire

Ni 2.5 to 4.0

Si 0.5 to 1.0

0.25 to 0.45 980 to 1770

Annealed aluminum wire Al>99.5 2.7 0.63 to 0.64 4200

Hard-drawn aluminum wire Al>99.5 2.7 0.60 to 0.62 4000

Aldrey wire

Si 0.4 to 0.6

Mg 0.4 to 0.5

Al remaining portion

0.50 to 0.55 3600

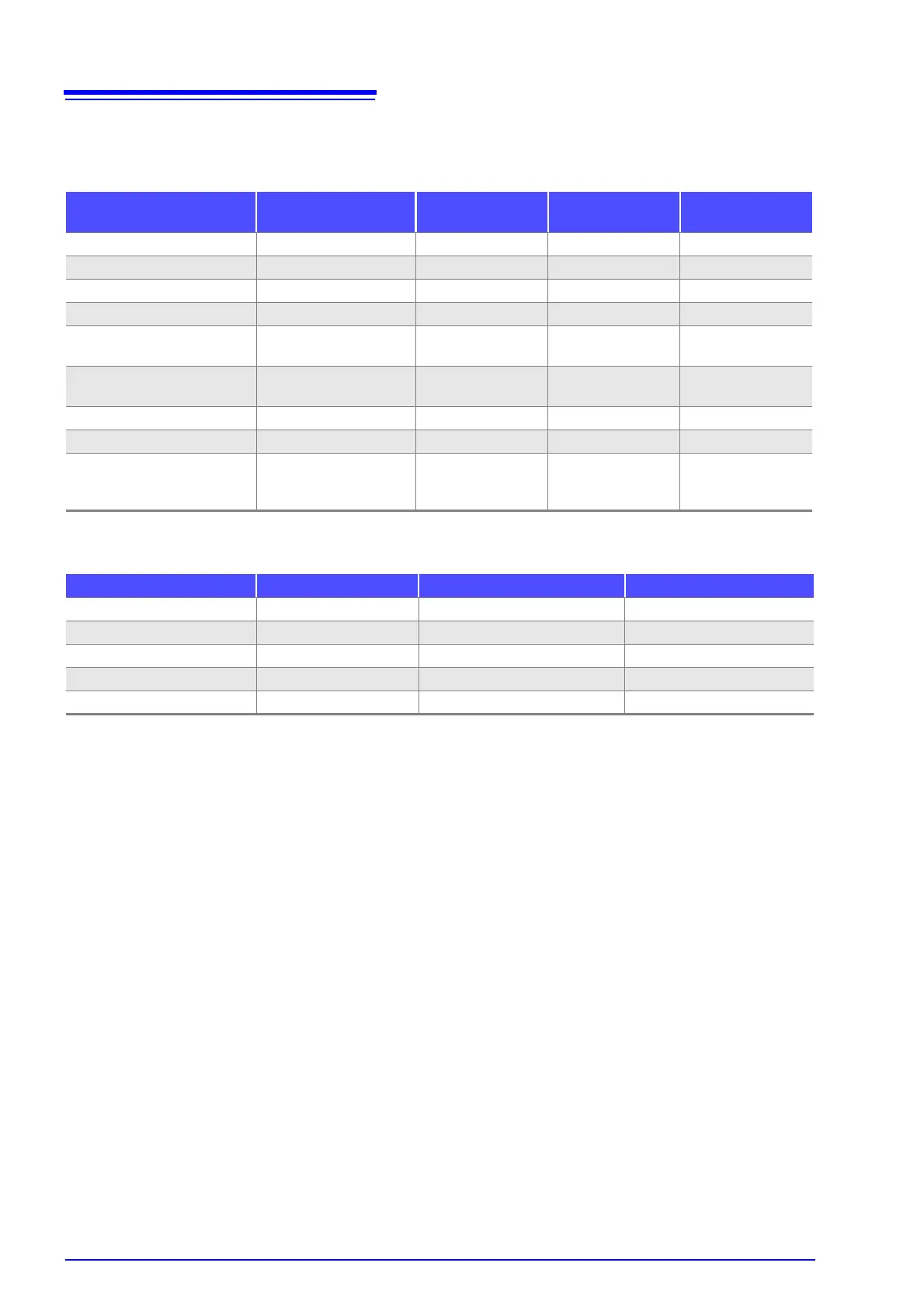

Diameter [mm] Annealed copper wire Tinned annealed copper wire Hard-drawn copper wire

0.01 to less than 0.26 0.98 0.93 -

0.26 to less than 0.29 0.98 0.94 -

0.29 to less than 0.50 0.993 0.94 -

0.50 to less than 2.00 1.00 0.96 0.96

2.00 to less than 8.00 1.00 0.97 0.97

ct

1

1

20

C

------------------- t20–+

--------------------------------------------=

20

1

1

0.00393 0.93

------------------------------------ 20 20–+

-----------------------------------------------------------------=

3650 ppm

Loading...

Loading...