FLIGHT CONTROLS / FLIGHT CONTROL SYSTEM GENERAL MAINTENANCE 9-9

CHANGE C3 ICON A5 / MAINTENANCE MANUAL

NOTE: Do NOT use metallic wool or solvents to clean the surface.

c. If internal corrosion is present, replace the cable.

3. Inspect cable for kinks. Kinked cables have strands out of position, which lead to unequal tension

and excessive wear at that part of the cable. Rather than straightening out kinked cables, replace

regardless of wear or broken wires.

4. Inspect cables for general wear. Fold each wing and visually inspect both the inboard rod end of

the inboard pushrod on the wing and the lower roll control cable terminal at the bottom of the roll

socket at the wing fold joint.

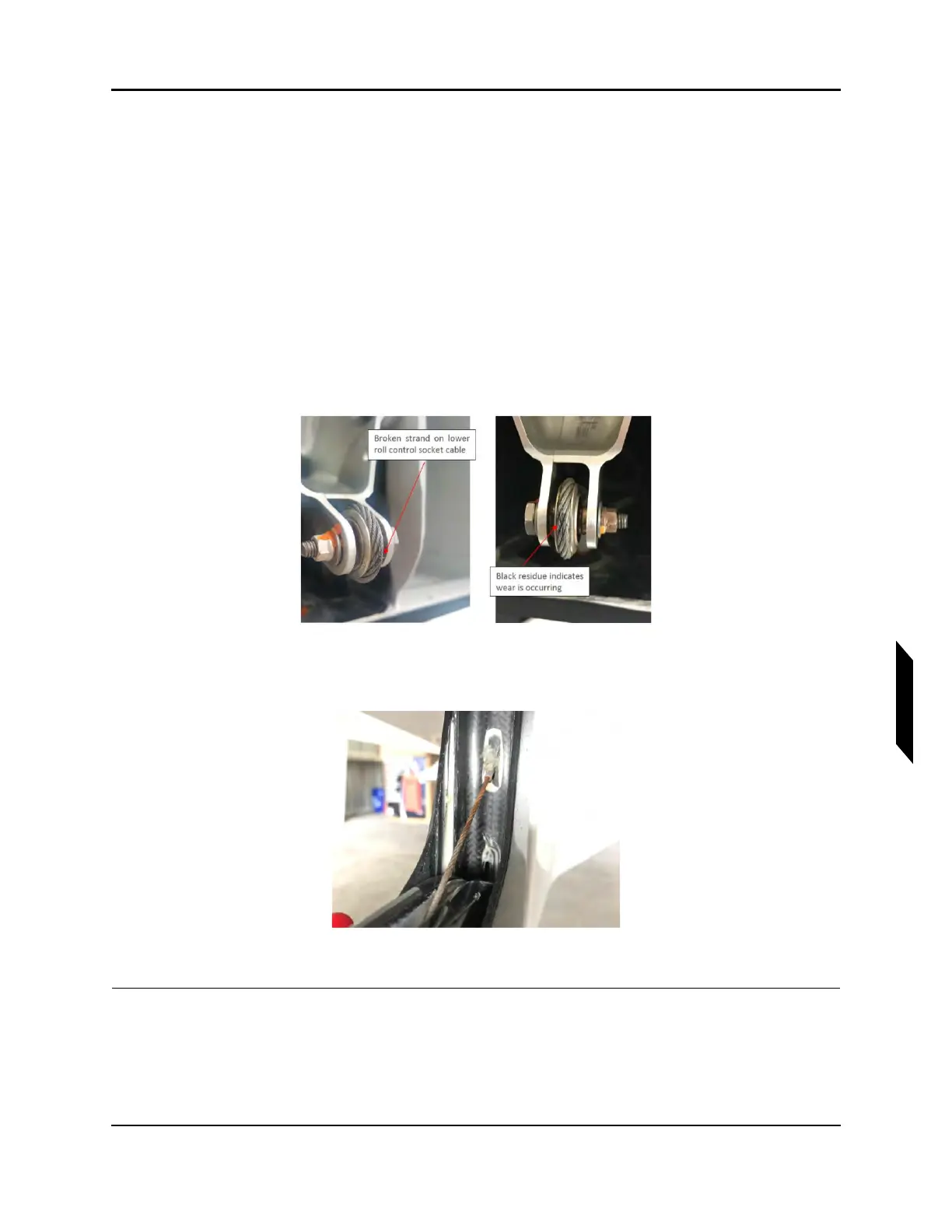

a. If there is evidence of wear on the rod end or the roll control cable as shown in Figure 9-4

carefully inspect the end of the roll control cable for any broken strands.

b. If there is no evidence of wear or corrosion on the rod end or roll cable—no further action

is needed.

FIGURE 9-4

BROKEN STRAND AND BLACK RESIDUE INDICATING WEAR ON LOWER ROLL

CONTROL CABLE.

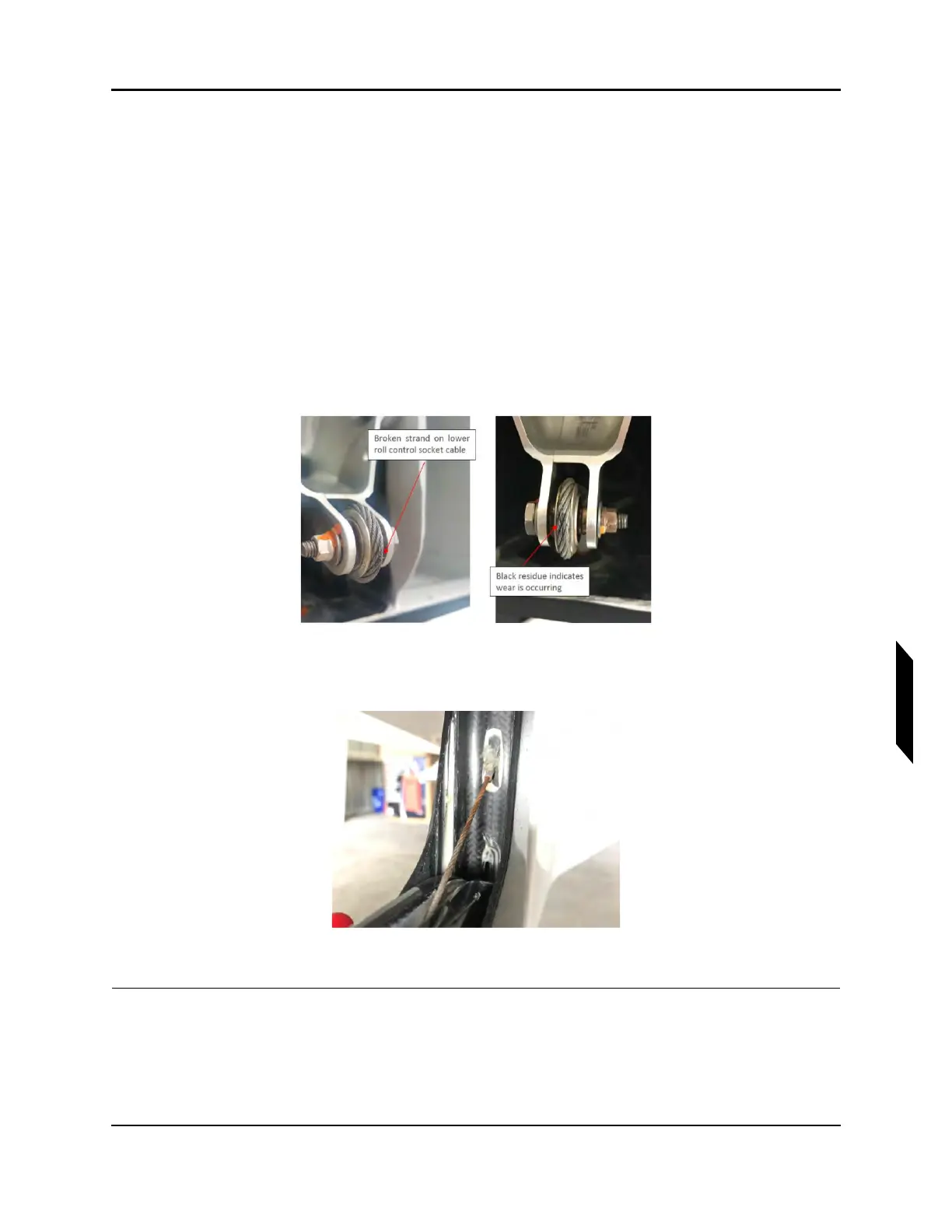

FIGURE 9-5

EXAMPLE OF CABLE SURFACE CORROSION.

VERIFICATION METHOD:

Ensure cables inspected fall within the acceptable conditions listed above. Otherwise follow the proce-

dure listed for each type of unacceptable condition.

Loading...

Loading...