14-80 LANDING GEAR / NOSE LANDING GEAR

ICON A5 / MAINTENANCE MANUAL CHANGE C2

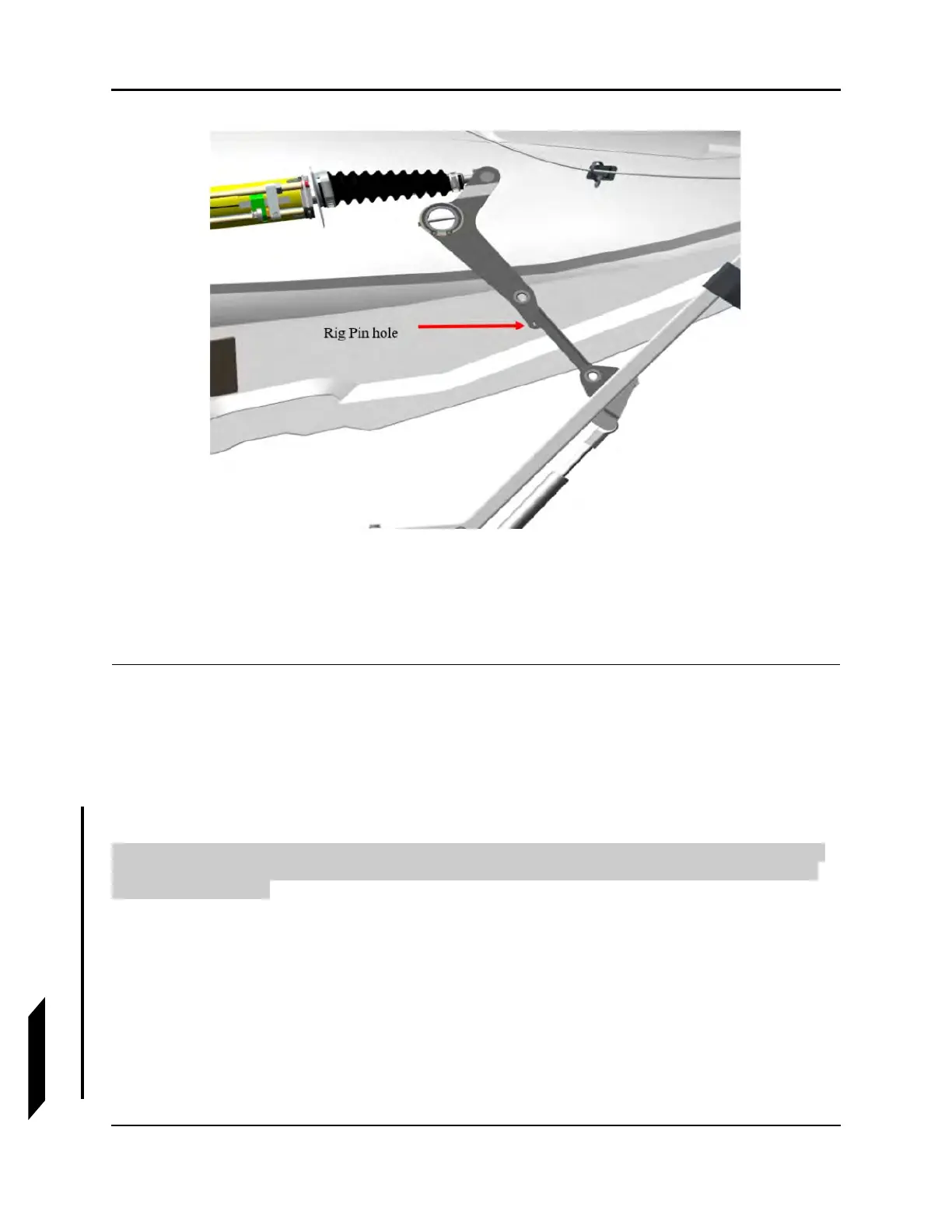

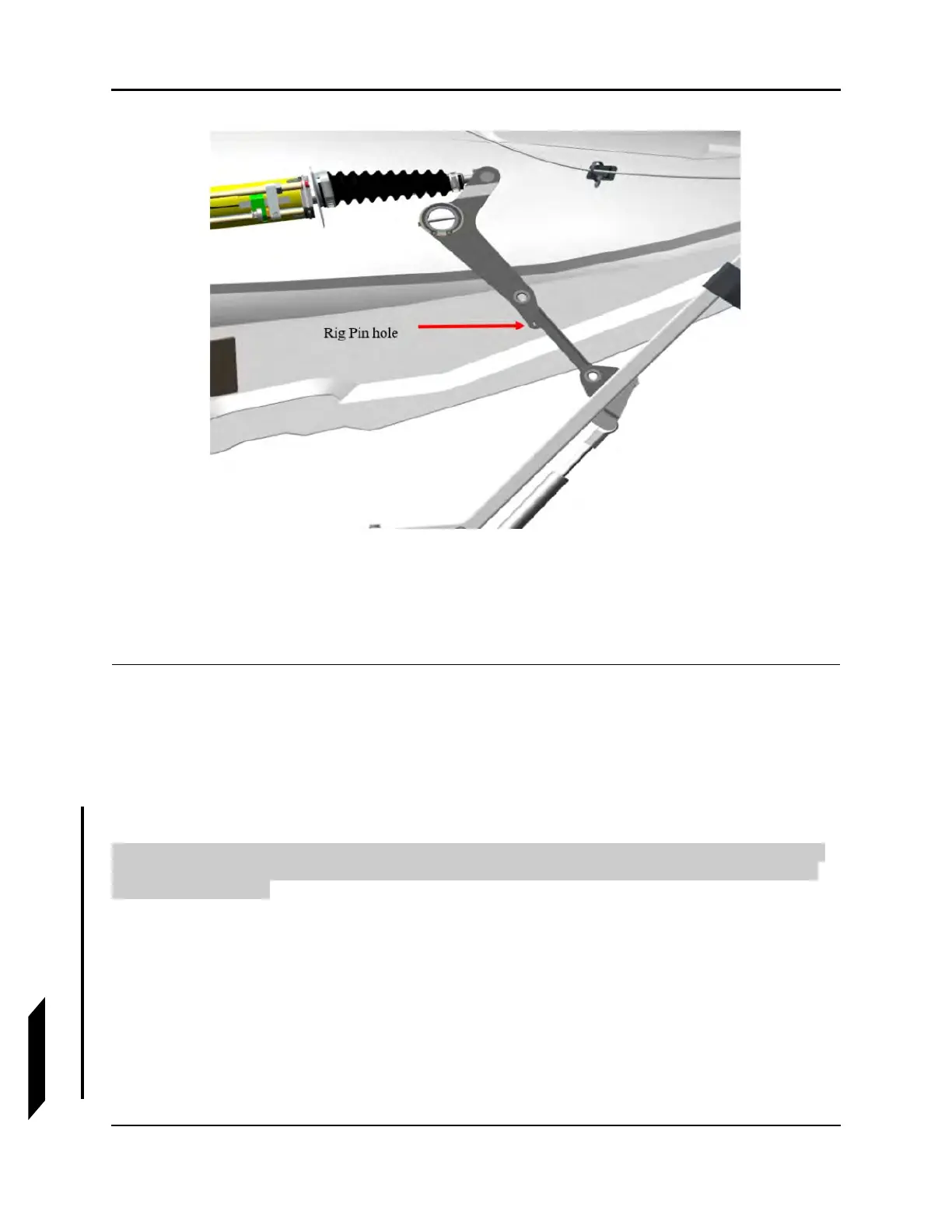

FIGURE 14-31

FIGURE OF RIG PIN HOLE

4. If adjustment is necessary, loosen jam nut of forward most Reed Switch saddle and rotate the

thumb wheel to adjust the actuator such that the rig pin slides freely into position.

5. Torque Jam nut to 36-40 in-lbs and check that hardware is secure.

VERIFICATION METHOD:

Verify no fuses blown and landing gear light shows positive gear down indication.

14.7.2.10Nose Wheel Tire Leak

This procedure should be used to identify and repair a slow nose wheel leak with the application of

sealant added through the valve core. Use the following procedure if it is suspected that the Nose

Wheel Tire has a leak.

TASK INFORMATION:

Type of Maintenance

Line

Level of Certification

LSA-RM

Task Specific Training Required

Loading...

Loading...