Platform Power Delivery Guidelines

174 Design Guide

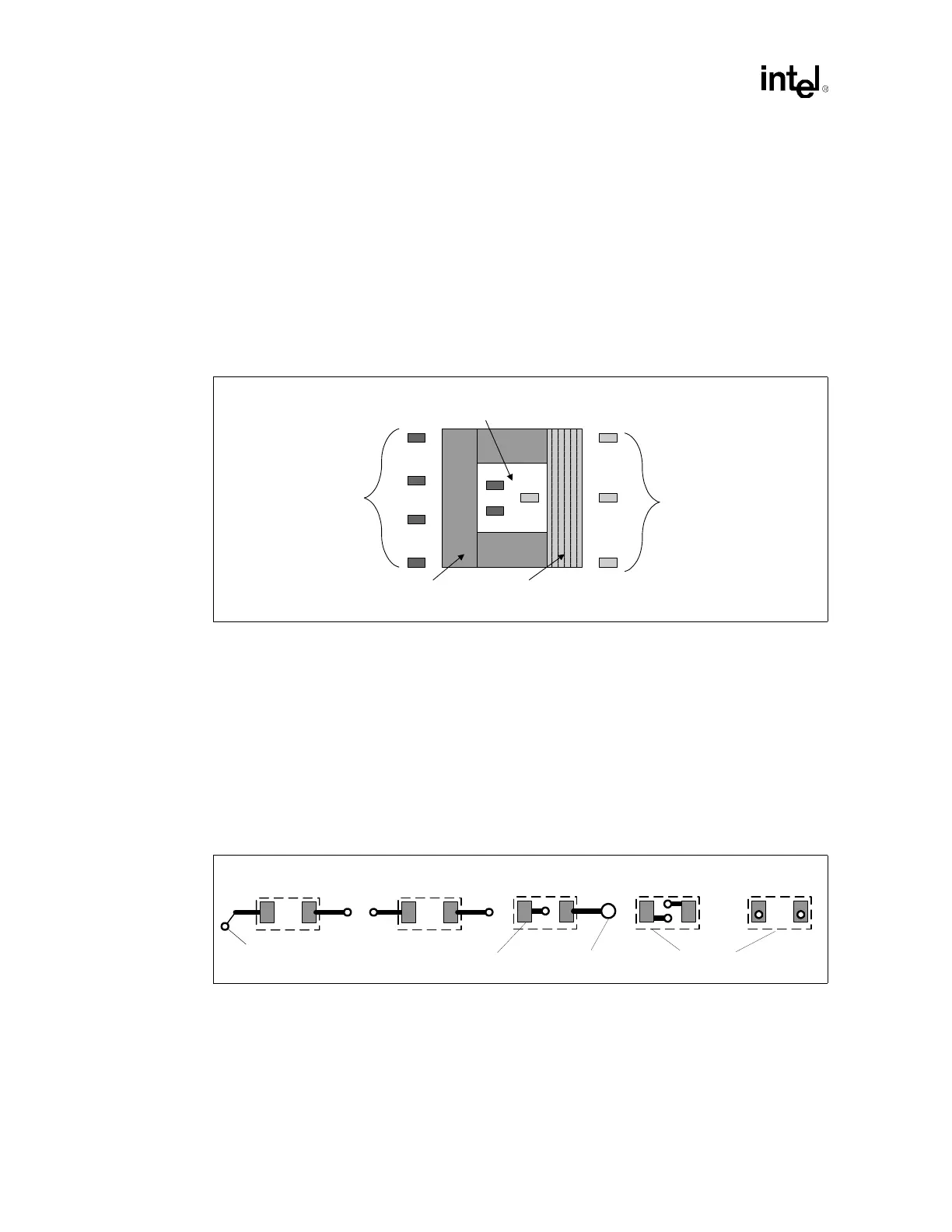

In addition, high-frequency decoupling may be required for signal integrity. System boards

designed using striplines with VCC_CPU and VSS references should not require high-frequency

decoupling beyond the recommendations listed in Table 12-5. For systems using microstrip

configurations, a return path discontinuity will exist between the processor and the baseboard due

to the baseboard traces having only one reference plane. These systems should distribute

decoupling capacitors, as shown in Figure 12-11 and described as follows:

• 4 minimum, 6 preferred 1 µF capacitors with 0805 packages distributed evenly over the data

lines.

• 3 minimum, 4 preferred 0.1 µF capacitors with 0805 packages distributed evenly over the

address and control lines.

Location of High-Frequency Decoupling

Place high-frequency decoupling as close to the power pins of the processor as physically possible.

Use both sides of the board if necessary for placing components to achieve the optimum proximity

to the power pins. This is vital because the inductance of the board's metal plane layers could

cancel the usefulness of these low inductance components.

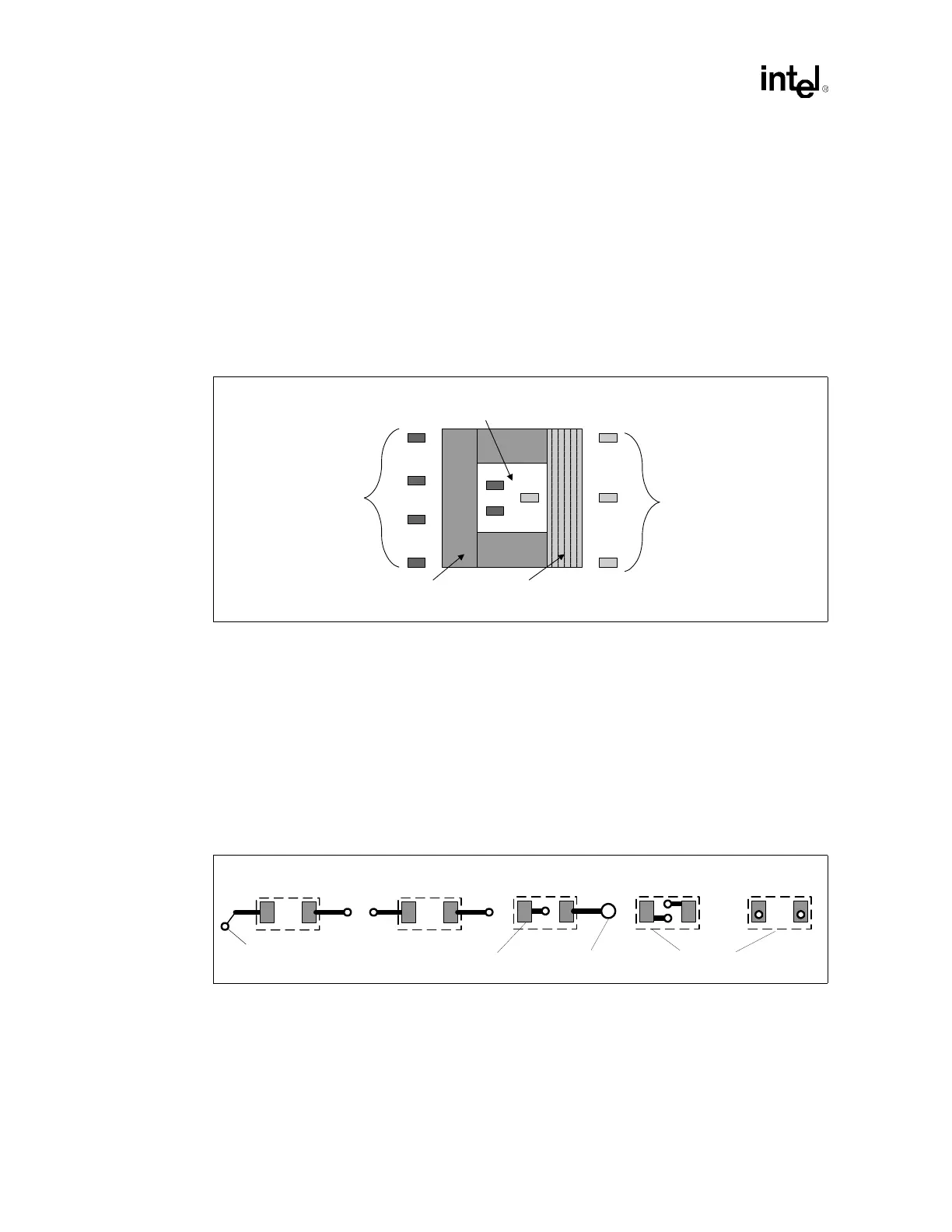

Shorten the path from the capacitor pads to the pins that it is decoupling. If possible, place the vias

connecting to the planes within the pad of the capacitor. If this is not possible, keep the traces as

short and wide as is feasible. Possibly one or both ends of the capacitor can be connected directly to

the pins of the processor without the use of a via. Figure 12-12 illustrates these concepts.

Figure 12-11. Decoupling Example for a Microstrip Baseboard Design

3-4 0.1 uF with 0805

body over the address

and control signals and

as close to the processor

package as possible.

4-6 0.1 uF with 0805

body over the data

signals and as close

to the processor

package as possible.

Data Pins

Address and

Control Pins

Cavity Under

Processor

Figure 12-12. 1206 Capacitor Pad and Via Layouts

Bad

Vias

Very Good

Pad

Capacitors

Good

Pin

Less Bad

Very Good

Loading...

Loading...