64

Procedure for Settin

Ins

ection Conditions

Cha

ter 5

5.6 Inspection Overview

To support for various inspection purposes, the PV310 has multiple types of inspection functions, which are

performed in accordance with the inspection conditions being different for each inspection function. In PV310, the

inspection function is called a checker. Only basic concepts of checker are described here, but if you want to

need more information about checkers, please refer to Section 6.

The Types of Checkers

Binary Window Counts the number of white or black pixels in a specified area and judges as OK or NG

using the measured number

Gray Window Calculates the gray average values of all pixels in a specified area and judges as OK or

NG using the measured number

Binary Edge Detects the edges between white and black and judges as OK or NG using the

measured number

Gray Edge Detects the point of a certain variation in brightness in accordance with the gray value

of each pixel and judges as OK or NG based on the number of detected pixels

Feature Extraction Detects a cluster of black or white pixels in a binary image and judges as OK or NG

depending on the measured number

Smart Matching Detects an image being equal to the saved image (template) based on the gray scale

value and judges as OK or NG

Contour Matching Detects an image similar to the saved image (template) based on the contour

information and judges as OK or NG in accordance with the correlation value

Flaw Detection Calculates a gray average value within the segmented range (cell). The PV310 judges

as OK or NG based on the difference in the gray average of neighboring cells

The PV310 has a support function, which enables you to execute the inspections shown in the table above in

accordance with the position or angle of an object.

Position Adjustment Detects the position of an object and executes inspection in the position where the

object was adjusted

Rotation Adjustment Executes inspection by rotating the object by the adjusted angle

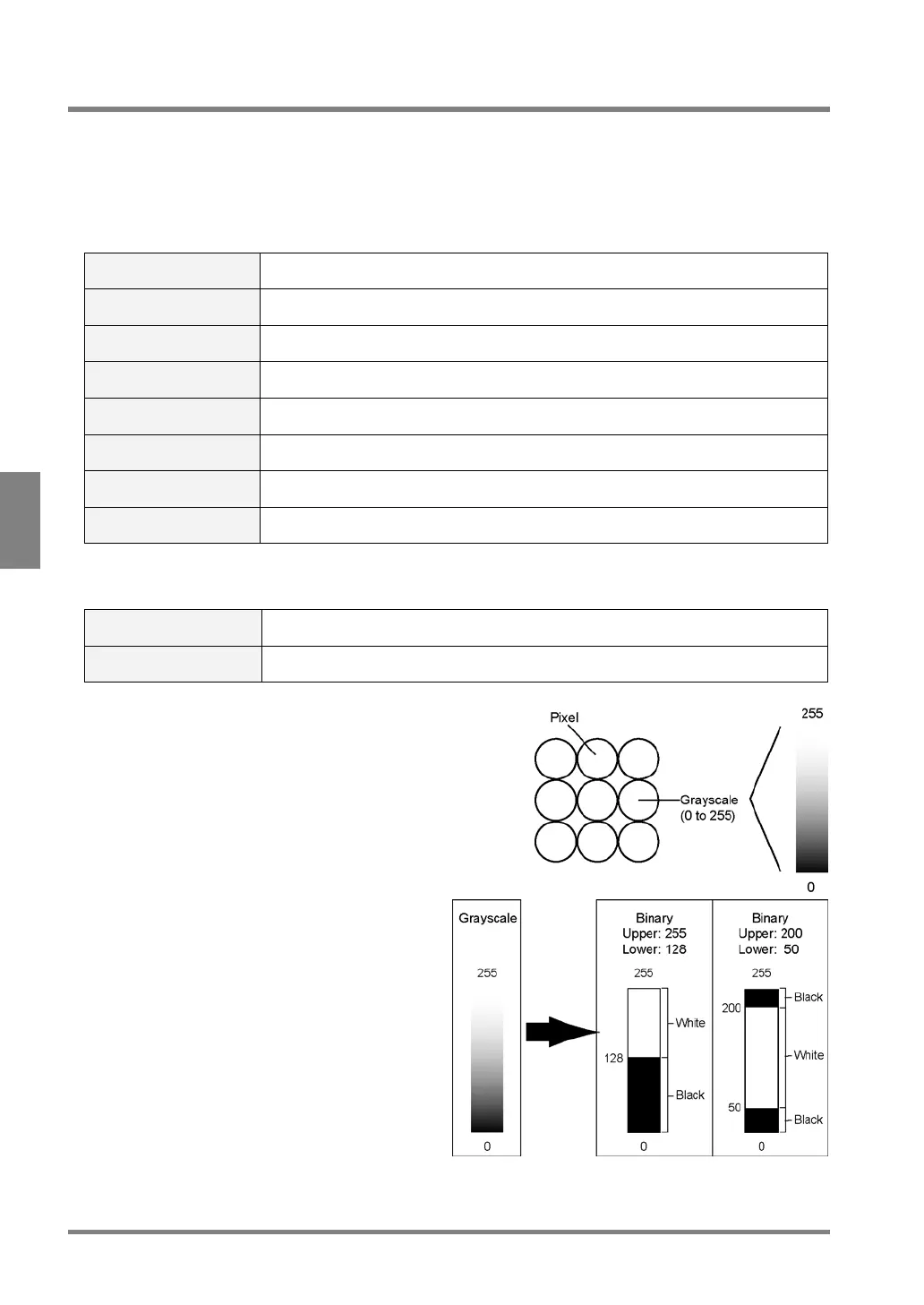

Gray Scale:

The process of capturing the signals from a camera as a 256

(0 to 255) grayscale image. The brightness of 256 grayscale is

called a gray value. The higher gray value the brighter pixel

and the lower gray value the darker pixel.

Binary Image:

In binary images, all pixels within the certain range

of gray scale are turned white and all pixels out of

the certain range of gray scale level are turned

black. The range of gray scale is called a slice

level]. Eight slice levels (A to H) can be saved for

each product type. Since the color information that

a binary image has is binary (white and black) color

information, the amount of the color information in a

binary image is smaller than that in a grayscale or

differential image. As a result, checkers can

process binary images faster than grayscale

images. Note that if the brightness of the image or

inspection object changes during inspection, a pixel

may change from white to black or vice versa.

Loading...

Loading...