•

Configure the Position to be the tip of the screwdriver tool where it contacts the screw.

•

Configure the Orientation so that the positive Z direction is aligned to the length of the

screws to be tightened.

You can visualize the X, Y and Z coordinates of the selected TCP to confirm it matches the

tool’s bit or socket.

The Screwdriving program node (see23.13.8. Screwdrivingon page191) uses the positive Z

direction of the selected TCP to follow the screw and calculate distances.

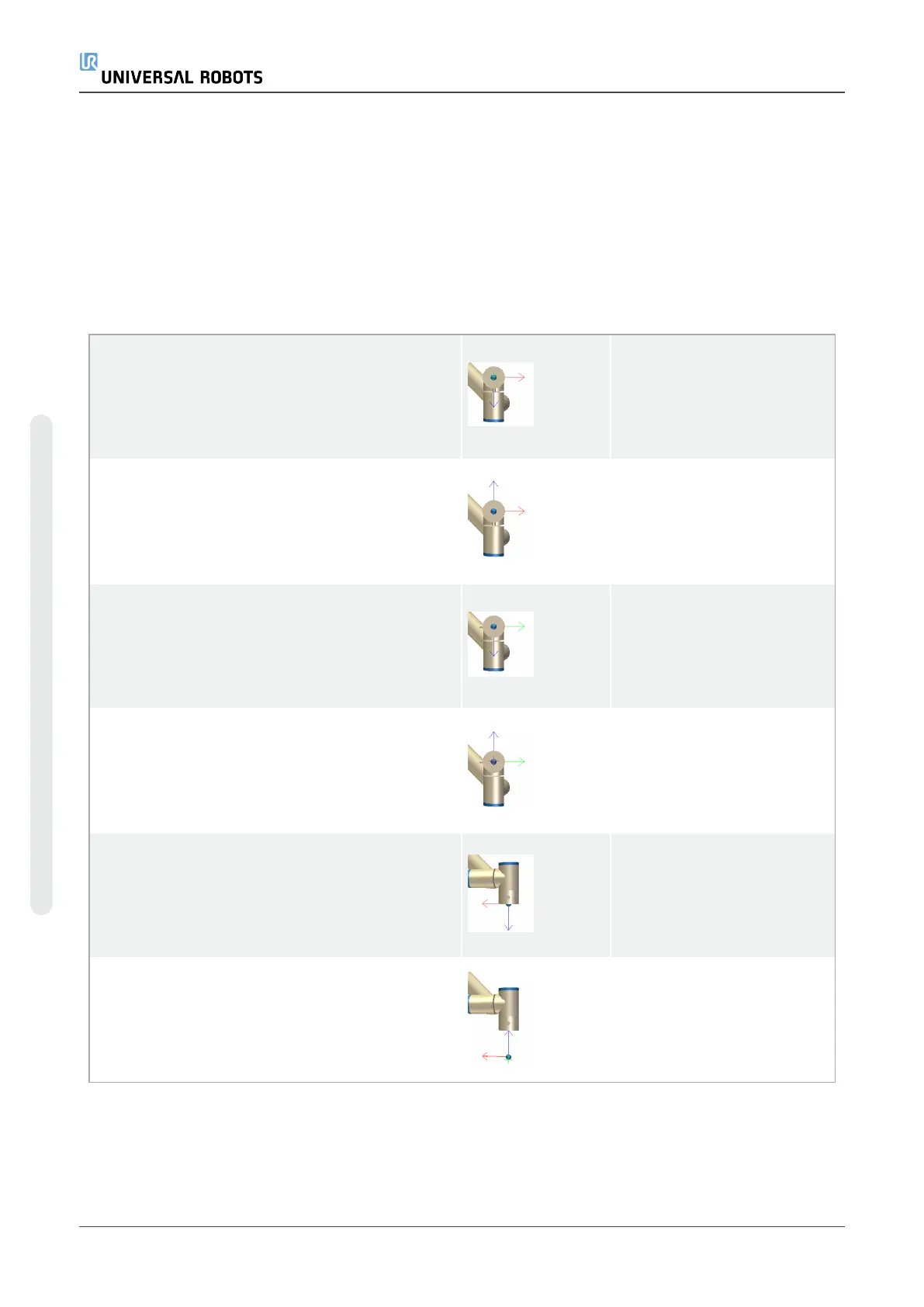

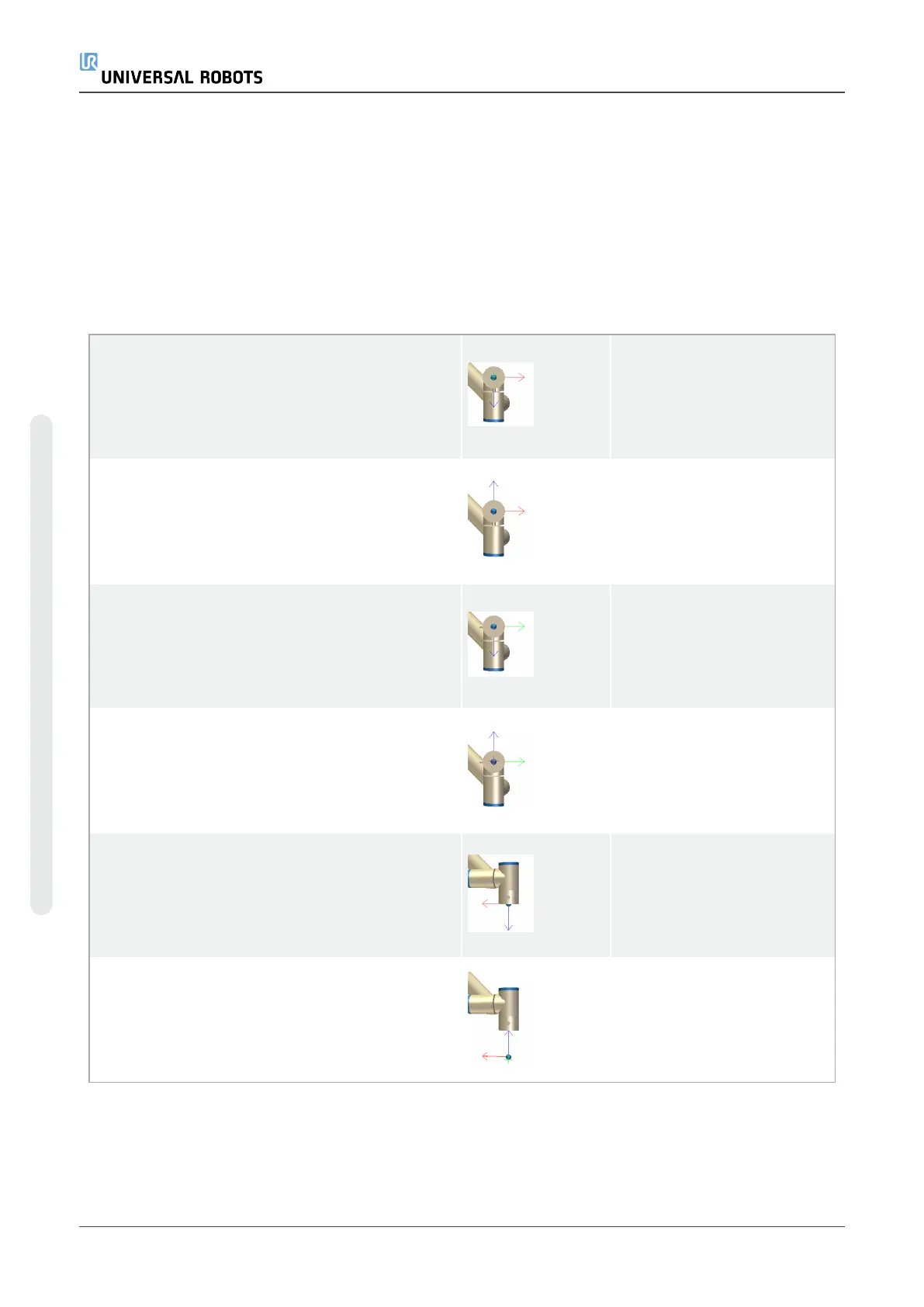

Typical Orientation values (in Rotation Vector [rad] notation) are illustrated in the following table.

Screwdriving axis parallel to the negative Y

direction of the robot’s tool flange

Orientation

•

RX: 1.5708 rad

•

RY: 0.0000 rad

•

RZ: 0.0000 rad

Screwdriving axis parallel to the positive Y

direction of the robot’s tool flange

Orientation

•

RX: -1.5708 rad

•

RY: 0.0000 rad

•

RZ: 0.0000 rad

Screwdriving axis parallel to the positive X

direction of the robot’s tool flange

Orientation

•

RX: 0.0000 rad

•

RY: 1.5708 rad

•

RZ: 0.0000 rad

Screwdriving axis parallel to the negative X

direction of the robot’s tool flange

Orientation

•

RX: 0.0000 rad

•

RY: -1.5708 rad

•

RZ: 0.0000 rad

Screwdriving axis parallel to the positive Z

direction of the robot’s tool flange

Orientation

•

RX: 0.0000 rad

•

RY: 0.0000 rad

•

RZ: 0.0000 rad

Screwdriving axis parallel to the negative Z

direction of the robot’s tool flange

Orientation

•

RX: 3.1416 rad

•

RY: 0.0000 rad

•

RZ: 0.0000 rad

UR5e 222 User Manual

24.Installation Tab

Copyright © 2009–2021 by UniversalRobotsA/S. All rights reserved.

Loading...

Loading...