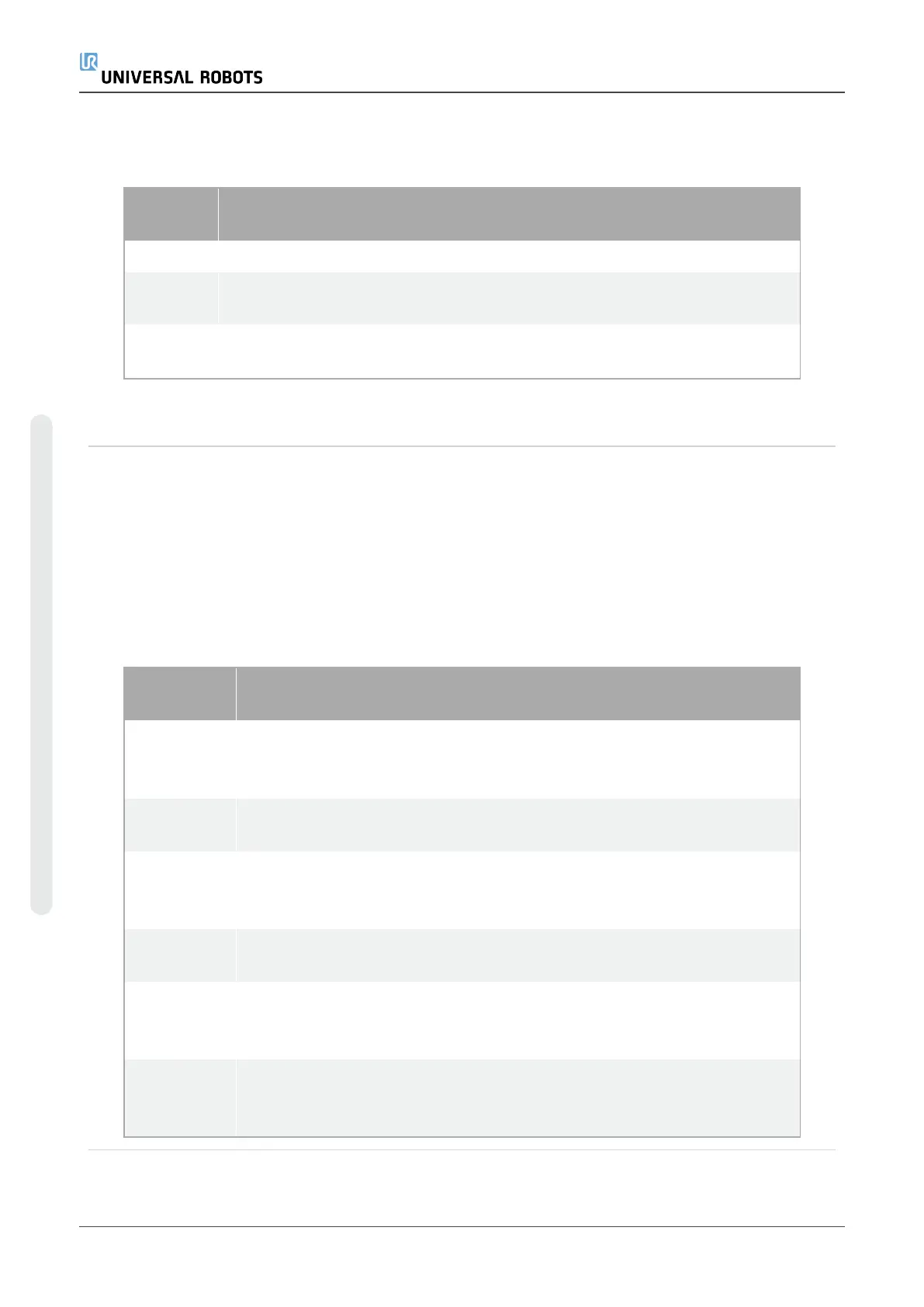

Depending on the circumstances, the robot can initiate three types of stop categories

defined according to IEC 60204-1. These categories are defined in the following table.

Stop

Category

Description

0 Stop the robot by immediate removal of power.

1

Stop the robot in an orderly, controlled manner. Power is removed once the

robot is stopped.

2

*Stop the robot with power available to the drives, while maintaining the

trajectory. Drive power is maintained after the robot is stopped.

*Universal Robots robots’ Category 2 stops are further described as SS1 or as SS2 type

stops according to IEC 61800-5-2.

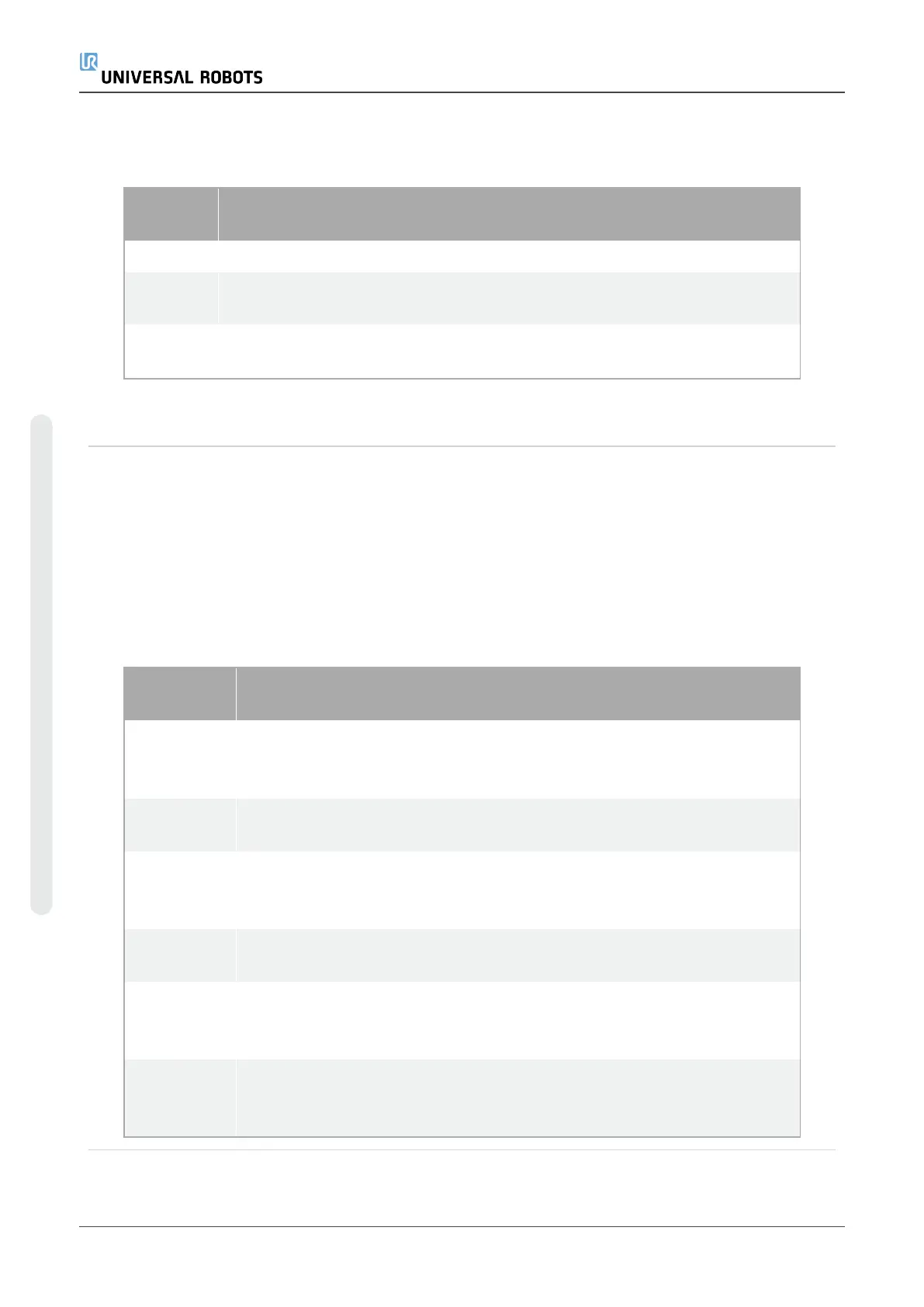

3.3. Configurable Safety Functions

Universal Robots robot safety functions, as listed in the table below, are in the robot but

are meant to control the robot system i.e. the robot with its attached tool/end effector.

The robot safety functions are used to reduce robot system risks determined by the risk

assessment. Positions and speeds are relative to the base of the robot.

Safety

Function

Description

Joint

Position

Limit

Sets upper and lower limits for the allowed joint positions.

Joint Speed

Limit

Sets an upper limit for joint speed.

Safety

Planes

Defines planes, in space, that limit robot position. Safety planes limit

either the tool/end effector alone or both the tool/end effector and the

elbow.

Tool

Orientation

Defines allowable orientation limits for the tool.

Speed Limit

Limits maximum robot speed. The speed is limited at the elbow, at the

tool/end effector flange, and at the center of the user-defined tool/end

effector positions.

Force Limit

Limits maximum force exerted by the robot tool/end effector and elbow

in clamping situations. The force is limited at the tool/end effector,

elbow flange and center of the user-defined tool/end effector positions.

UR5e 18 User Manual

3.Safety-related Functions and Interfaces

Copyright © 2009–2021 by UniversalRobotsA/S. All rights reserved.

Loading...

Loading...