5.8 L: Protection Functions

YASKAWA ELECTRIC SIEP C710616 27G YASKAWA AC Drive A1000 Technical Manual 291

L5-05: Fault Reset Operation Selection

Setting 0: Count successful restarts

The drive will continuously attempt to restart. If it restarts successfully, the restart counter is increased. This operation is

repeated each time a fault occurs until the counter reaches the value set in L5-01.

Setting 1: Count restart attempts

The drive will try to restart using the time interval set in parameter L5-04. A record is kept of the number of attempts to

restart to the drive, regardless of whether or not those attempts were successful. When the number of attempted restarts

exceeds the value set to L5-01, the drive gives up trying to restart.

L6: Torque Detection

The drive provides two independent torque detection functions that trigger an alarm or fault signal when the load is too

heavy (oL), or suddenly drops (UL). They are set up using the L6- parameters. To indicate th

e underload or overload

condition to an external device, digital outputs should be programmed as shown below.

Note: When overtorque occurs in the application, the drive may stop due to overcurrent (oC) or overload (oL1). To prevent this, an

overload situation should be indicated to the controller before oC or oL1 occur in the drive. Use the torque detection for this

purpose. Use undertorque detection to discover application problems like a torn belt, a pump shutting off, or other similar

trouble.

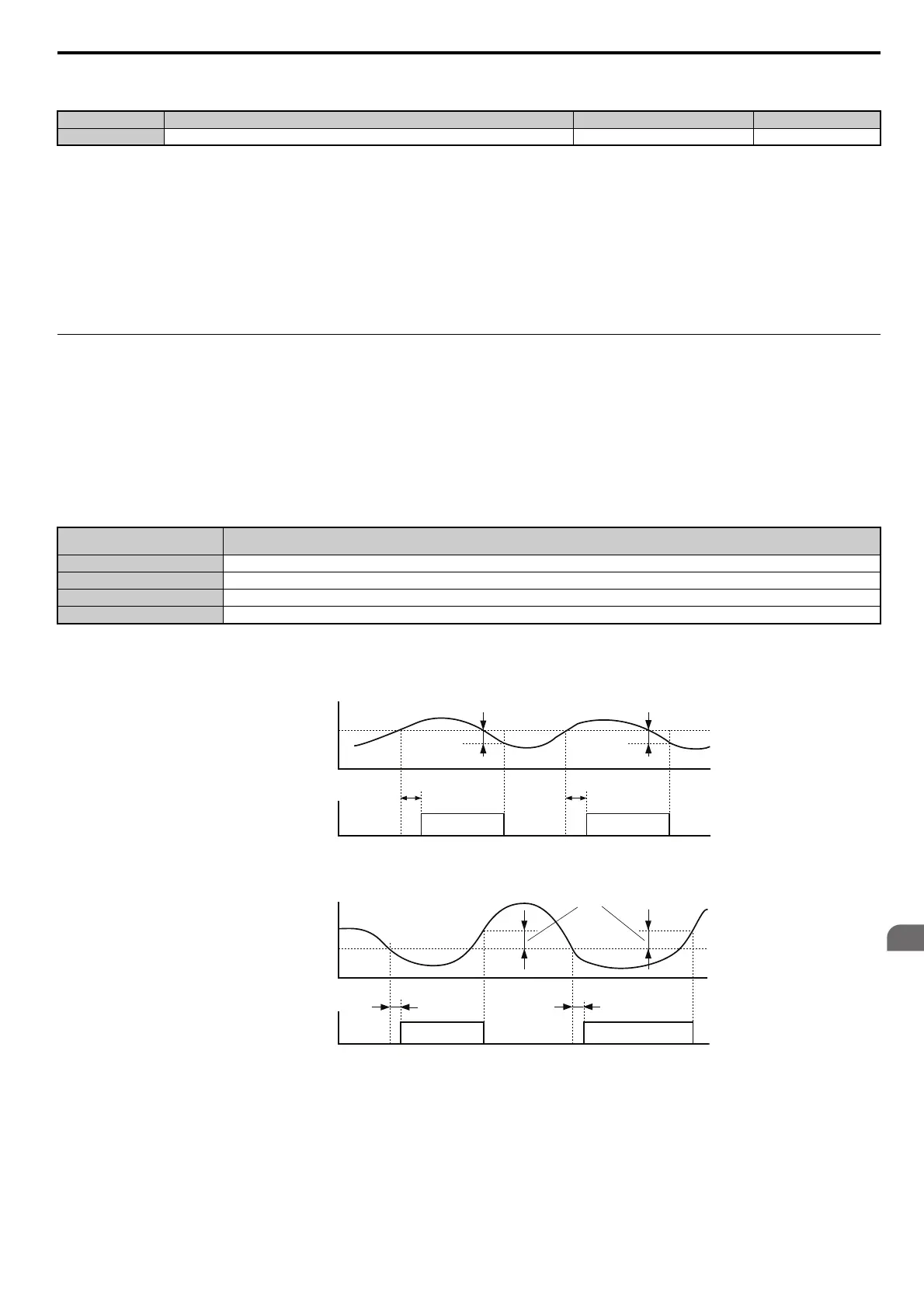

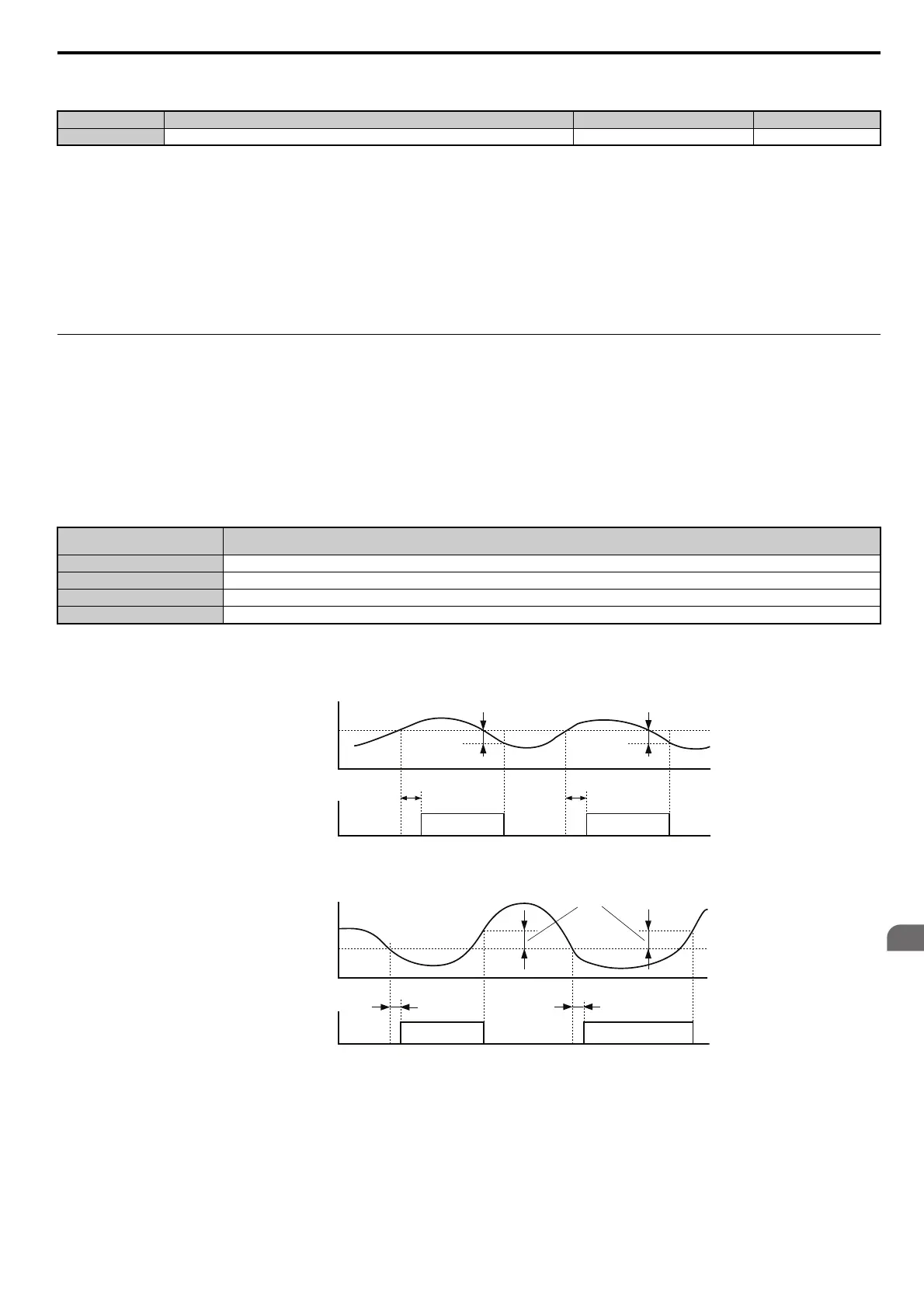

Figure 5.106 and Figure 5.107 show the function of overtorque and undertorque detection.

Figure 5.106

Figure 5.106 Overtorque Detection Operation

Figure 5.107

Figure 5.107 Undertorque Detection Operation

Note: 1. The torque detection

function uses a hysteresis of 10% of the drive rated output current and motor rated torque.

2. In V/f, V/f w/PG and OLV/PM, the level is set as a percentage of the drive rated output current. In OLV, CLV, AOLV/PM and CLV/

PM, it is set as a percentage of the motor rated torque.

No. Name Setting Range Default

L5-05 Fault Reset Operation Selection 0 or 1 0

H2-01, H2-02, H2-03

Setting

Description

B Torque detection 1, N.O. (output closes when overload or underload is detected)

17 Torque detection 1, N.C. (output opens when overload or underload is detected

18 Torque detection 2, N.O. (output close when overload or underload is detected)

19 Torque detection 2, N.C. (output opens when overload or underload is detected)

Motor current / torque

L6-02/05

10 % hysteresis

Torque detection 1 (NO)

or

Torque detection 2 (NO)

L6-03/06

ON

L6-03/06

10 % hysteresis

ON

Motor current / torque

L6-02/05

10 % hysteresis

Torque detection 1 (NO)

or

Torque detection 2 (NO)

L6-03/06

ON

L6-03/06

ON

Loading...

Loading...