6.10 Troubleshooting without Fault Display

YASKAWA ELECTRIC SIEP C710616 27G YASKAWA AC Drive A1000 Technical Manual 373

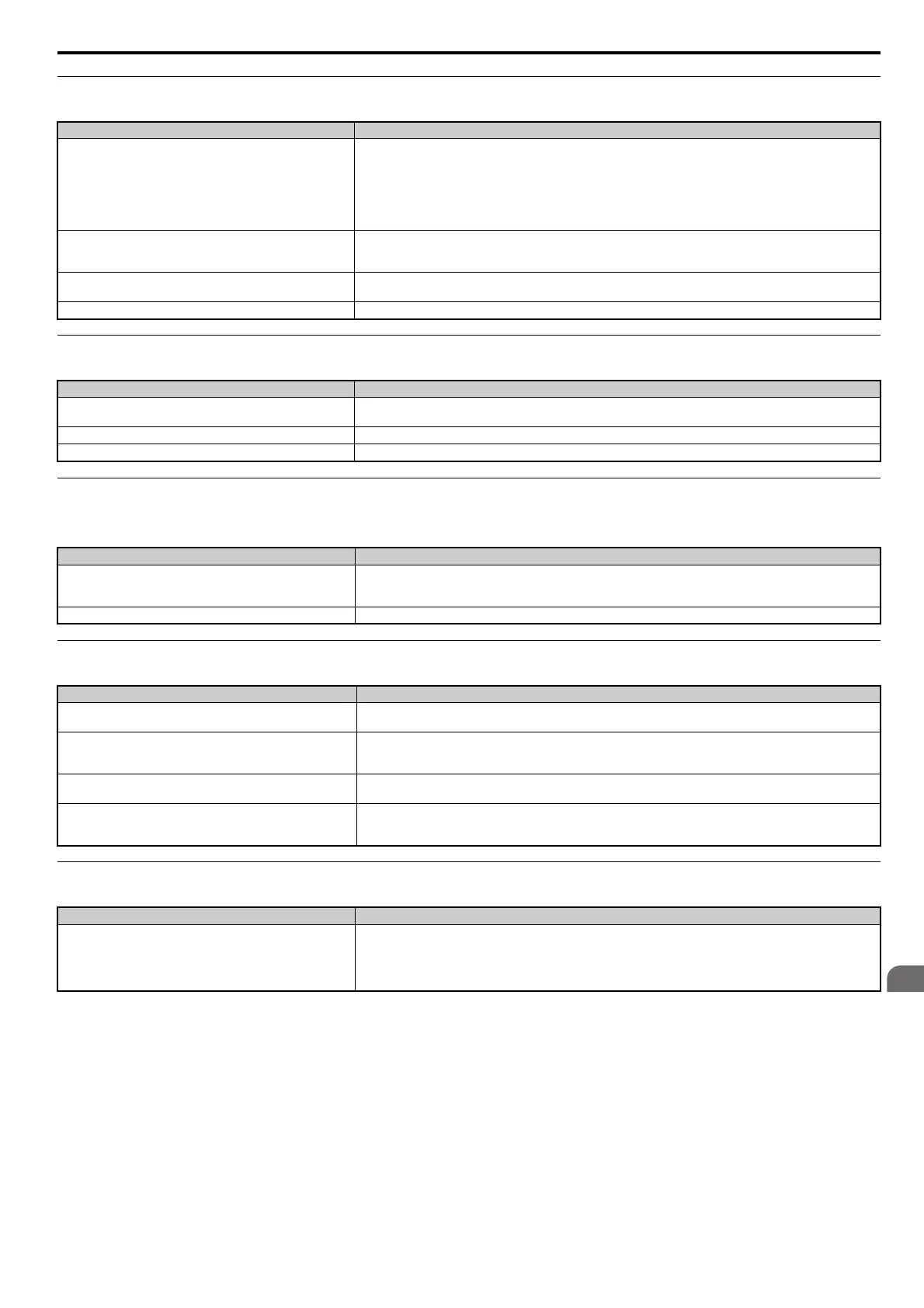

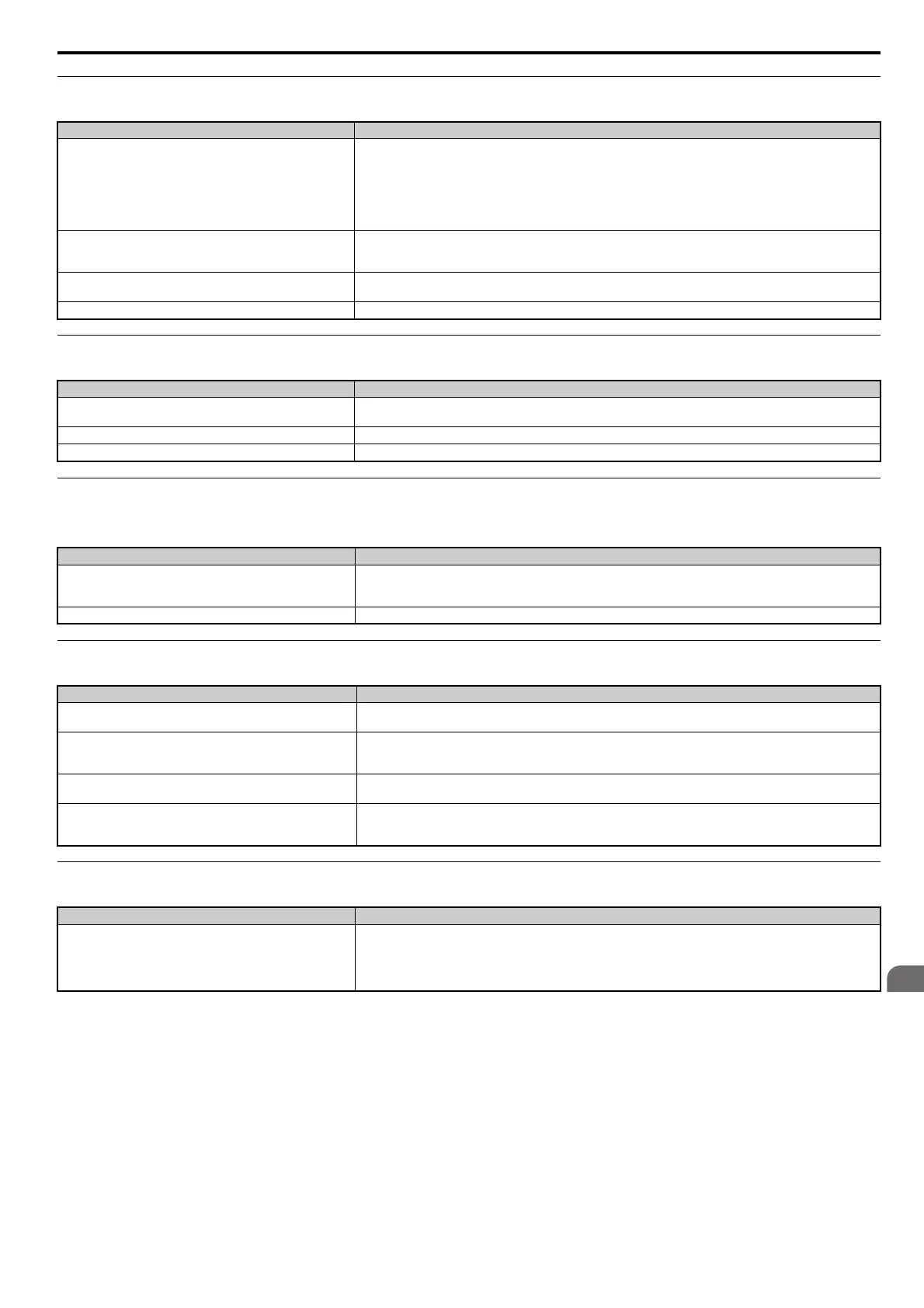

PID Output Fault

Insufficient Starting Torque

Motor Rotates After the Drive Output is Shut Off (Motor Rotates During DC Injection

Braking)

Output Frequency is not as High as Frequency Reference

Buzzing Sound from Motor at 2 kHz

Cause Possible Solutions

No PID feedback input.

• Check the multi-function analog input terminal settings.

• Set multi-function analog input terminal A1, A2, or A3 for PID feedback (H3-02, H3-10, or H3-06 = “B”).

• A signal input to the terminal selection for PID feedback is needed.

• Check the connection of the feedback signal.

• Check the various PID-related parameter settings.

• No PID feedback input to the terminal causes the value detected to be 0, causing a PID fault and the drive to operate

at max frequency.

The level of detection and the target value do not correspond with

each other.

• PID control keeps the difference between target and detection values at 0. Set the input level for the values relative to

one another.

• Use analog input gains H3-03 and H3-11 to adjust PID target and feedback signal scaling.

Reverse drive output frequency and speed detection. When output

frequency rises, the sensor detects a speed decrease.

Set PID output for reverse characteristics (b5-09 = 1).

Adjustment made to PID parameter settings are insufficient. Refer to b5: PID Control on page 167 for details.

Cause Possible Solutions

Auto-Tuning has not yet been performed (required for vector

control modes).

Perform Auto-Tuning. Refer to Motor Performance Fine-Tuning on page 326.

The control mode was changed after performing Auto-Tuning. Perform Auto-Tuning again.

Only Stationary Auto-Tuning was performed. Perform Rotational Auto-Tuning.

Cause Possible Solutions

DC Injection Braking is set too low and the drive cannot decelerate

properly.

• Adjust the DC Injection braking settings.

• Increase the current level for DC Injection Braking (b2-02).

• Increase the DC Injection Braking time at stop (b2-04).

The stopping method is set so that the drive coasts to stop. Set b1-03 (Stopping Method Selection) to 0 or 2.

Cause Possible Solutions

Frequency reference is set within the range of the Jump frequency.

• Adjust the parameters used for the Jump frequency function (d3-01, d3-02, d3-03).

• Enabling the Jump frequency prevents the drive from outputting the frequencies specified in the Jump range.

Upper limit for the frequency reference has been exceeded.

• Set the maximum output frequency and the upper limit for the frequency reference to more appropriate values

(E1-04, d2-01).

• The following calculation yields the upper value for the output frequency = E1-04 d2-01 / 100

Large load triggered Stall Prevention function during acceleration.

• Reduce the load.

• Adjust the Stall Prevention level during acceleration (L3-02).

Motor runs at following speed.

b2-01 Motor speed < E1-09

Set b1-21 (Start Condition Selection at Closed Loop Vector Control) to 1.

Set E1-09 (Minimum Output Frequency) to a value lower than the setting for b2-01 (DC Injection Braking Start

Frequency).

Cause Possible Solutions

Exceeded 110% of the rated output current of the drive while

operating at low speeds.

• If the output current rises too high at low speeds, the carrier frequency is automatically reduced and causes a whining

or buzzing sound.

• If the sound is coming from the motor, disable carrier frequency derating (L8-38 = 0).

• Disabling the automatic carrier frequency derating increases the chances of an overload fault (oL2). Switch to a larger

capacity motor if oL2 faults occur too frequently.

Loading...

Loading...