5.8 L: Protection Functions

294 YASKAWA ELECTRIC SIEP C710616 27G YASKAWA AC Drive A1000 Technical Manual

L6-11: Mechanical Weakening Detection Start Time

Sets the drives cumulative operation time at which Mechanical Weakening Detection is activated. If U4-01 reaches the

L6-11 value, the function is activated.

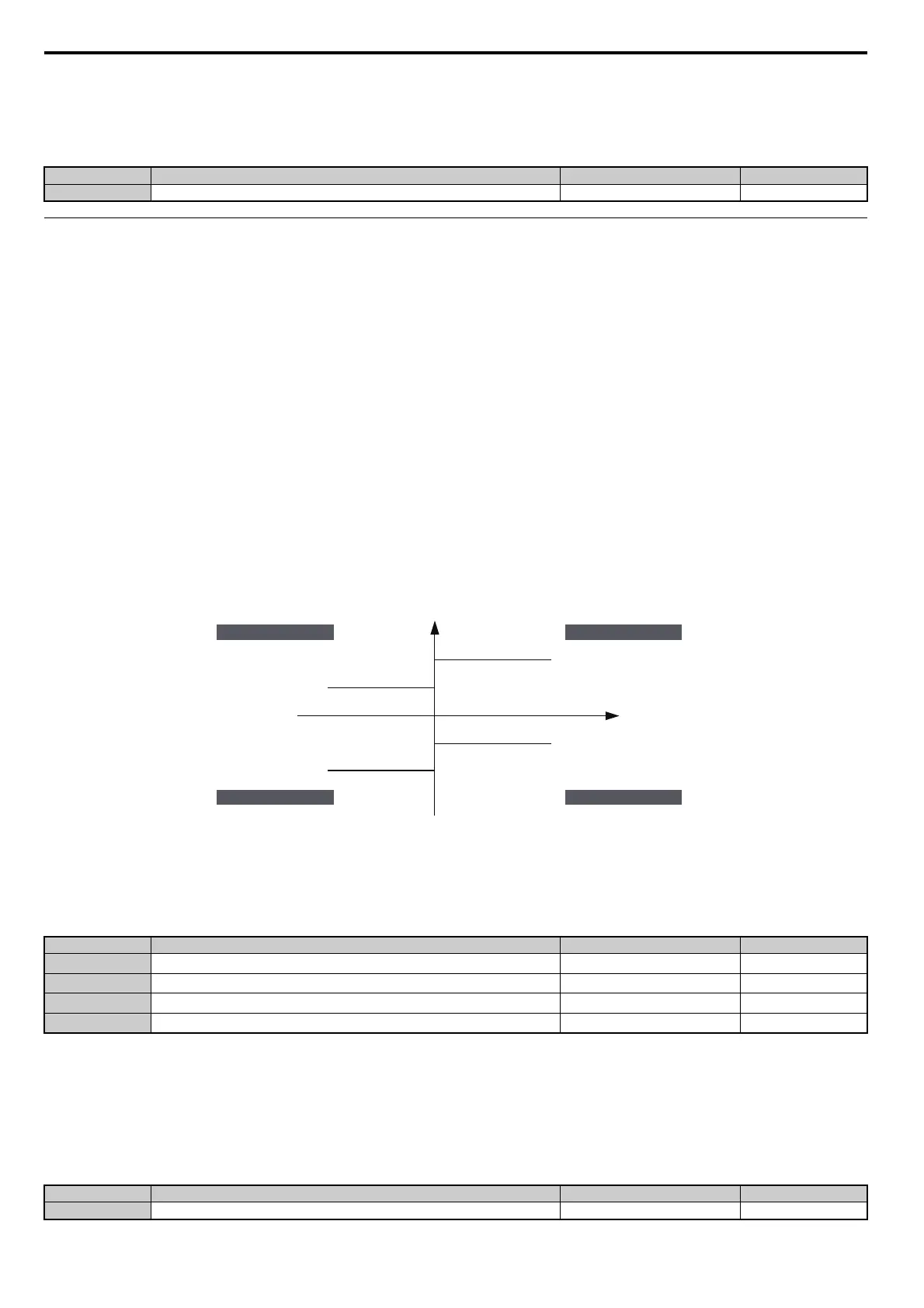

L7: Torque Limit

The torque limit function can be used to limit the torque in each of the four quadrants individually and thereby protect the

machinery. It can be used in OLV, CLV, AOLV/PM, and CLV/PM control modes. The limit can be either set by

parameters or by analog inputs. A digital output programmed for “During torque limit” (H2-01, H2-02, H2-03 = 30) can

be switched when the drive is operating at the torque limit.

Setting Torque Limits

The torque limits are defined by parameters L7-01 to L7-04 for each of the four operation quadrants. Analog inputs can

also be used to either define a general limit for all operation conditions (H3-02, H3-06, H3-10 = 15) or for setting

separate limits for each operation condition (H3-02, H3-06, H3-10 = 10, 11, or 12). Figure 5.108 shows which of the

limit settings is applied in

each quadrant.

If two limit values are defined for the same operation

conditions, the drive will use the lower value.

Note: The maximum output torque is ultimately limited by the drive output current (max. 150% of drive rated current in HD, 120% in

ND). Output torque will not exceed the limit set for the drive rated current, even if the torque limits are set to higher values.

Example: If parameter L7-01 = 130%, L7-02 to L7-04 = 200%, and a general torque limit of 150% is set by an analog

input (H3-02, H3-06, H3-10 = 15), then the torque limit in quadrant 1 will be 130%, but 150% in all other quadrants.

Figure 5.108

Figure 5.108 Torque Limit Parameters and Analog Input Settings

L7-01 to L7-04: Torque Limits

These parameters set the torque limits in each quadrant.

Note: If the multi-function analog input is programmed for “10: Forward torque limit”, “11: Reverse torque limit”, “12: Regenerative

torque limit”, or “15: General torque limit”, the drive uses the lower value in L7-01 through L7-04, or analog input torque limit.

L7-06: Torque Limit Integral Time Constant

Sets the integral time constant for the torque limit function. Decrease this setting for faster torque limit response. Increase

it if oscillation occur when operating at the torque limit.

No. Name Setting Range Default

L6-11 Mechanical Weakening Detection Start Time 0 to 65535 h 0 h

No. Name Setting Range Default

L7-01

Forward Torque Limit

0 to 300% 200%

L7-02

Reverse Torque Limit

0 to 300% 200%

L7-03

Forward Regenerative Torque Limit

0 to 300% 200%

L7-04

Reverse Regenerative Torque Limit

0 to 300% 200%

No. Name Setting Range Default

L7-06 Torque Limit Integral Time Constant 5 to 10000 ms 200 ms

positive torque reference

negative torque reference

10: Positive Torque Limit

12: Regenerative Torque Limit

15: Torque Limit

Parameter L7-04

REV motor rotation

11: Negative Torque Limit

15: Torque Limit

Parameter L7-02

10: Positive Torque Limit

15: Torque Limit

Parameter L7-01

FWD motor rotation

11: Negative Torque Limit

12: Regenerative Torque Limit

15: Torque Limit

Parameter L7-03

quadrant 2

quadrant 3

quadrant 1

quadrant 4

REV run regenerative

REV run motoring

FWD run motoring

FWD run regenerative

Loading...

Loading...