6.2 Motor Performance Fine-Tuning

328 YASKAWA ELECTRIC SIEP C710616 27G YASKAWA AC Drive A1000 Technical Manual

Fine-Tuning Advanced Open Loop Vector Control for PM Motors

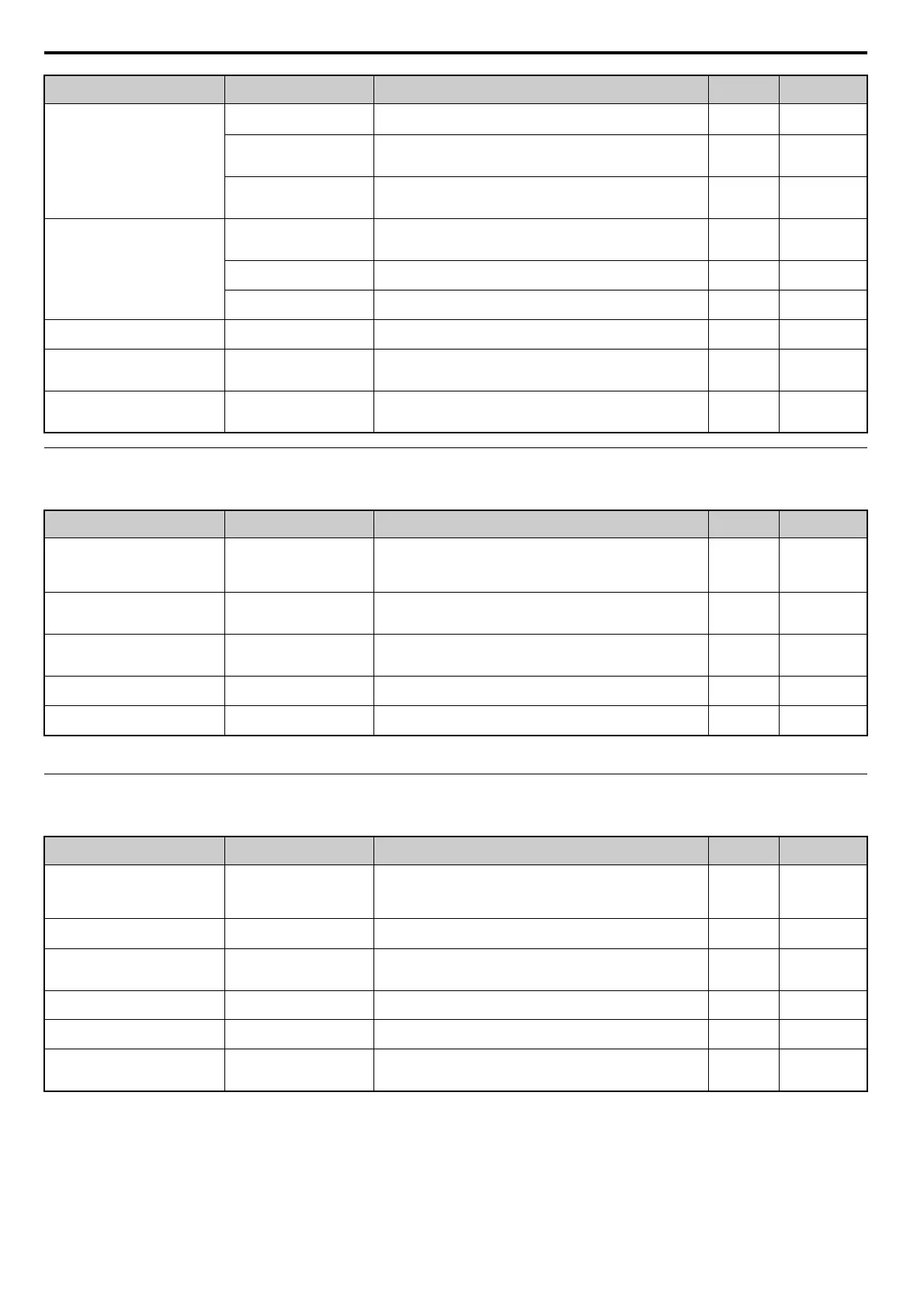

Table 6.5 Parameters for Fine-Tuning Performance in AOLV/PM

Fine-Tuning Closed Loop Vector Control for PM Motors

Table 6.6 Parameters for Fine-Tuning Performance in CLV/PM

Oscillation at start or the motor stalls

Pull-In Current during Accel/

De

cel (for PM Motors) (n8-51)

Increase the pull-in current set in n8-51 50%

Increase in steps

of 5%

DC Injection Braking Current

(b2-02

), DC Injection Time at

Start (b2-03)

Use DC Injection Braking at start to align the rotor. Be aware that this

oper

ation can cause a short reverse rotation at start.

b2-02 = 50%

b2-03 = 0.0 s

b2-03 = 0.5 s

Increase b2-02 if

ne

eded

Load Inertia Ratio (n8-55)

Increase the load inertia ratio.

No

te: Setting this value too high can cause overcompensation and motor

oscillation.

0

Close to the actual

loa

d inertia ratio

Stalling or oscillation occur when load

is

applied during constant speed

Pull-In Current Compensation

T

ime Constant (for PM Motors)

(n8-47)

Decrease n8-47 if hunting occurs

during constant speed 5.0 s

Reduce in

increments of 0.2 s

Pull-In Current (for PM Motors)

(n8-48)

Increase the pull-in current in n8-48. 30%

Increase in

i

ncrements of 5%

Load Inertia Ratio (n8-55) Increase the load inertia ratio. 0

Close to the actual

loa

d inertia ratio

Hunting or oscillation occur

Speed feedback De

tection Gain

(for PM Motors) (n8-45)

Increase the speed feedback detectio

n gain in n8-45. 0.8

Increase in

i

ncrements 0.05

STO fault trips even if the load is not

to

o high

Induced Voltage Constant (for

PM Motors) (E5-09 or E5-24)

• Check and adjust the induced

voltage constant.

• Check the motor name plate, the dat

a sheet or contact the motor

manufacturer for getting data.

dep. on drive

capacity

and

motor code

Refer to the motor

data sheet or the

nameplate.

Stalling or STO occurs at high speed as

th

e output voltage becomes saturated.

Output Voltage Limit (for PM

Motors) (n8-62)

Set the value of the input voltage to parameter n8-62.

Never set the value higher than the actual input voltage.

200 Vac or 400

Va c

Set the value lower

th

an the actual

input voltage.

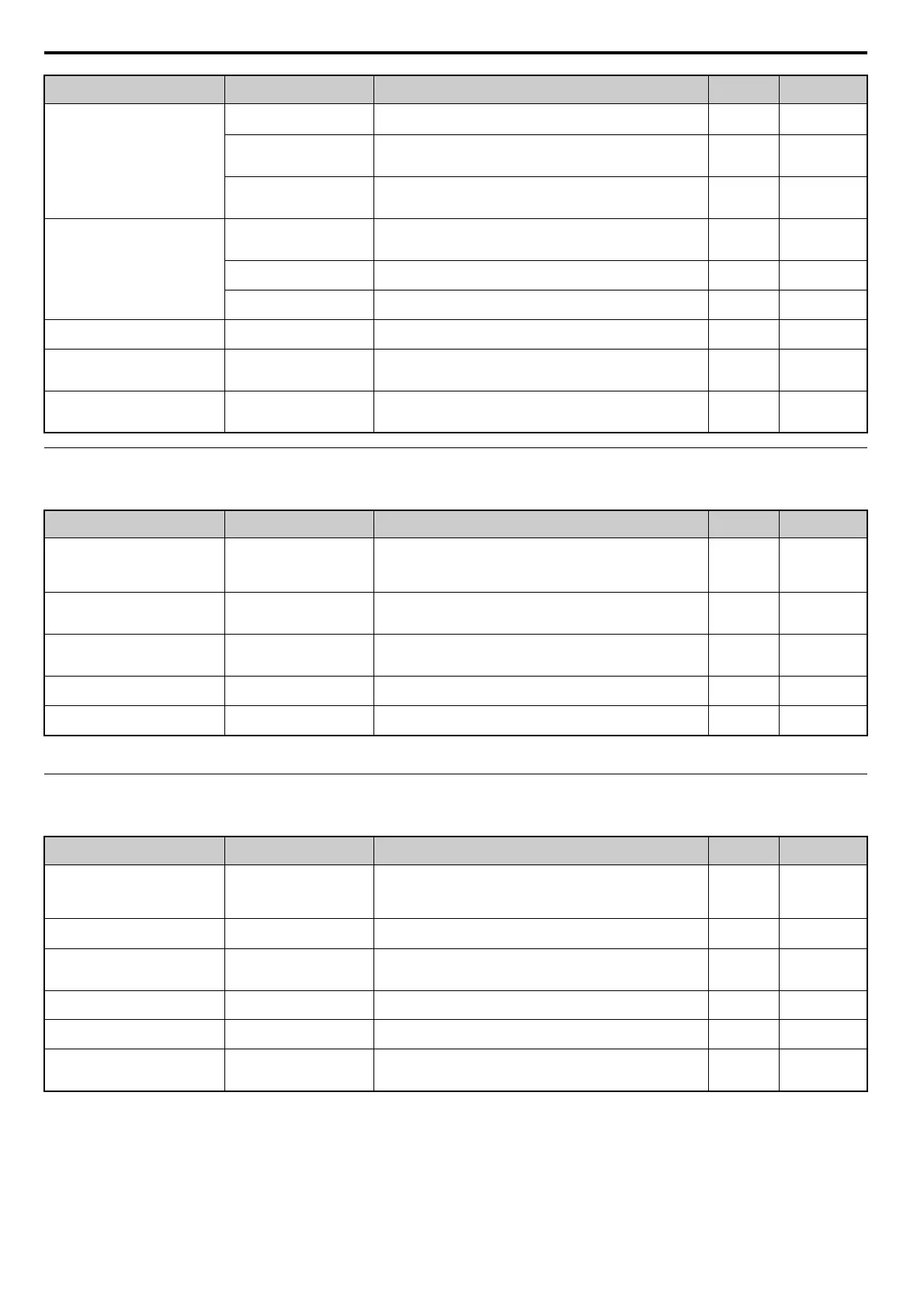

Problem Parameter No. Corrective Action Default

Suggested

Setting

• Poor torque or speed response

• Motor hunting and oscillation

ASR Proportional Gain 1

(C5-01)

ASR Proportional Gain 2

(C5-03)

• If motor torque and speed response are

too slow, gradually increase the

setting by 5.

• If motor hunting and oscillation occur, decrease the setting.

• Parameter C5-03 needs to be adjusted only if C5-05 > 0.

10.00 5.00 to 30.00

<1>

<1> Optimal settings will differ between no-load and loaded operation.

• Poor torque or speed response

• Motor hunting and oscillation

ASR Integral Time 1 (C5-02)

ASR Integral Time 2 (C5-04)

• If motor torque and speed response are

too slow, decrease the setting.

• If motor hunting and oscillation occur, increase the setting.

• Parameter C5-03 needs to be adjusted only if C5-05 > 0

0.500 s

0.300 to

1.000 s

<1>

Trouble maintaining the ASR

proportional gain or the integral time at

the low or high end of the speed range

ASR Gain Switching Frequency

(C

5-07)

Have the drive switch between two different ASR proportional gain and

integral time settings based on the output frequency.

0.0%

0.0 to Max min

-1

Motor hunting and oscillation

ASR Primary Delay Time

C

onstant (C5-06)

If the load is less rigid and subject to oscillation, increase this setting. 0.010 s

0.016 to

0.035 s

<1>

Motor stalling makes normal operation

impossible

Motor parameters

(E1-, E5-)

Check the motor parameter settings. – –

Problem Parameter No. Corrective Action Default

Suggested

Setting

• Poor torque or speed response

• Motor hunting and oscillation

ASR Proportional Gain 1

(C5-01)

ASR Proportional Gain 2

(C5-03)

• If motor torque and speed response are

too slow, gradually increase the

setting by 5.

• If motor hunting and oscillation occur, decrease the setting.

• Perform ASR Gain Auto-Tuning if possible

20.00 10.00 to 50.00

<1>

<1> Optimal settings will differ between no-load and loaded operation.

• Poor torque or speed response

• Motor hunting and oscillation

ASR Integral Time 1 (C5-02)

ASR Integral Time 2 (C5-04)

• If motor torque and speed response are too slow, decrease the setting.

• If motor hunting and oscillation occur, increase the setting.

0.500 s

0.300 to

1.000 s

<1>

ASR proportional gain or the integral

time at the low or high end of the speed

range

ASR Gain Switching Frequency

(C

5-07)

Have the drive switch between two different ASR proportional gain and

integral time settings based on the output frequency.

0.0%

0.0 to Max min

-1

Motor hunting and oscillation

ASR Primary Delay Time

Constant (C5-06)

If the load is less rigid and subject to oscillation, increase this setting. 0.016 s

0.004 to

0.020 s

<1>

Motor stall makes normal operation

impossible

Motor parameters

(E1-, E5-)

Check the motor parameter settings. – –

Overshoot or undershoot at speed

changes wi

th high inertia load.

Feed Forward Control (n5-01)

Inertia Auto-Tuning (T2-01 = 8)

Enable Feed Forward Control by setting parameter n5-01 = 1 and perform

Inertia Auto-Tuning. If Auto-Tuning cannot be performed set parameters

C5-17, C5-18 and n5-03 manually.

0 1

Problem Parameter No. Corrective Action Default

Suggested

Setting

Loading...

Loading...