6.10 Troubleshooting without Fault Display

372 YASKAWA ELECTRIC SIEP C710616 27G YASKAWA AC Drive A1000 Technical Manual

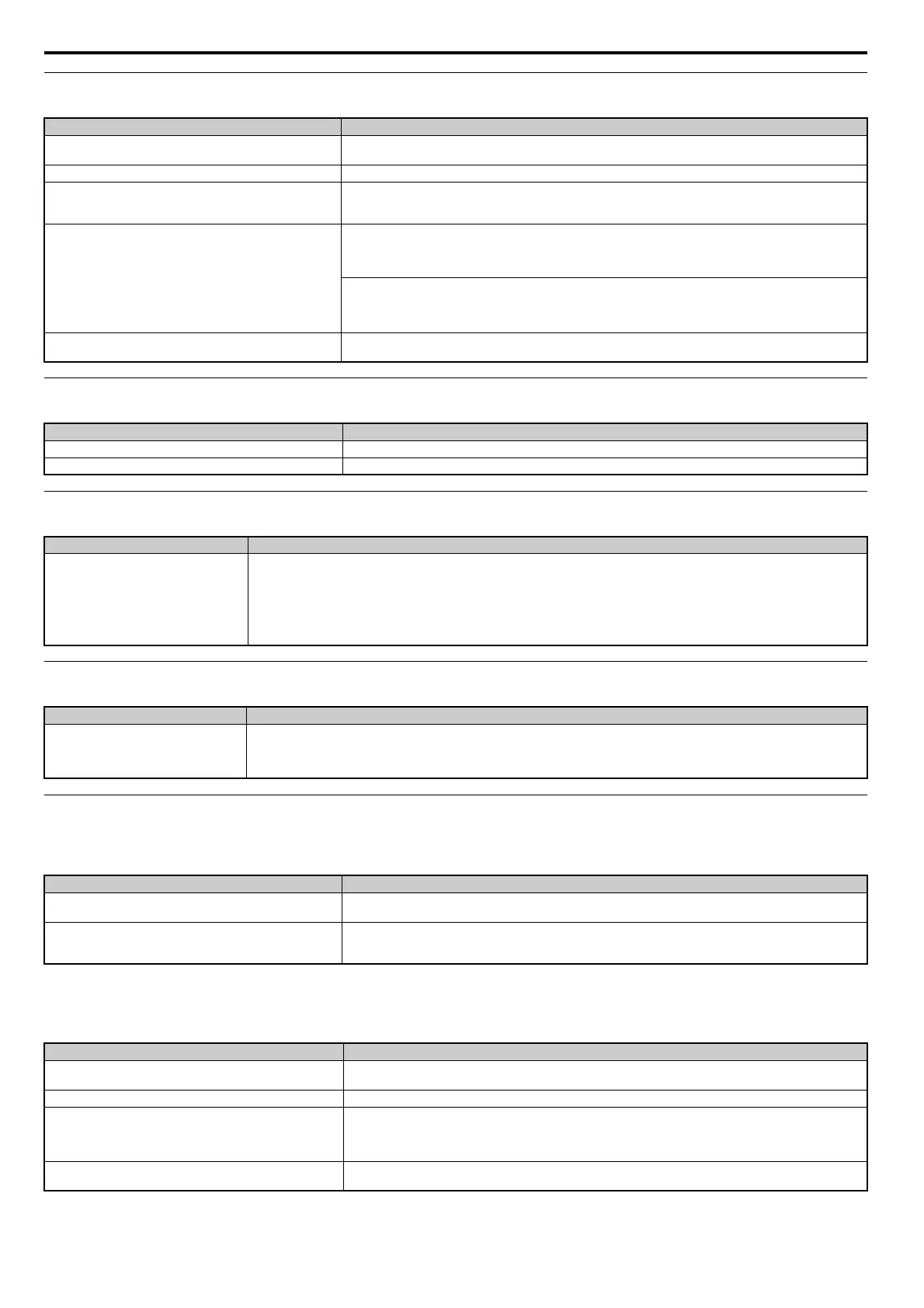

Deceleration Takes Longer Than Expected with Dynamic Braking Enabled

Load Falls When Brake is Applied (Hoist-Type Applications)

Noise From Drive or Motor Cables When the Drive is Powered On

Equipment for Residual Current Monitoring/Detection (RCM/RCD) Trips During Run

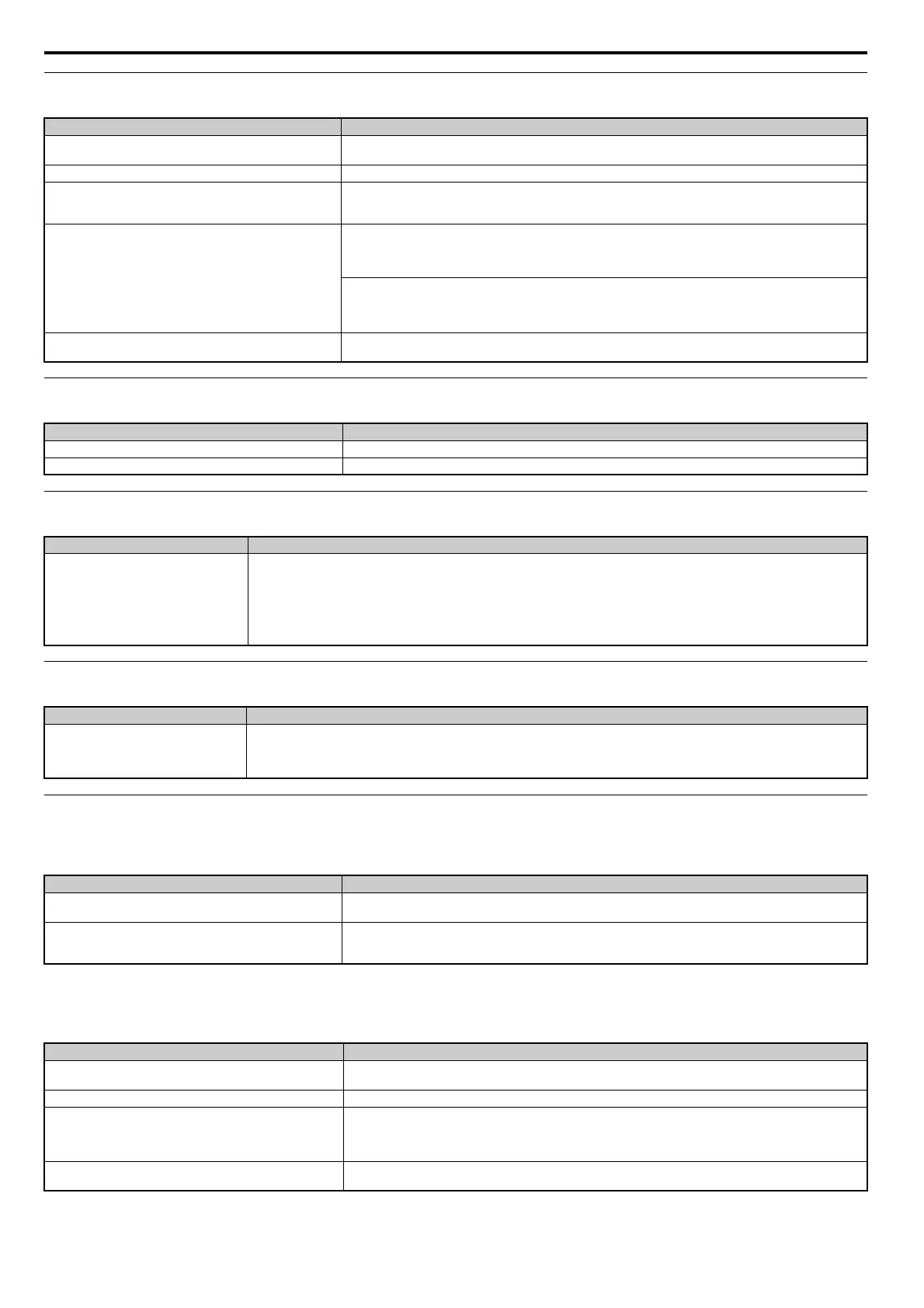

Connected Machinery Vibrates When Motor Rotates

Unexpected Noise from Connected Machinery

Note: The drive may have trouble assessing the status of the load due to white noise generated from using Swing PWM (C6-02 = 7 to A).

Oscillation or Hunting

Cause Possible Solutions

L3-04 is set incorrectly.

• Check the Stall Prevention level during deceleration (L3-04).

• If a dynamic braking option has been installed, disable Stall Prevention during deceleration (L3-04 = 0).

The deceleration time is set too long. Set deceleration to more appropriate time (C1-02, C1-04, C1-06, C1-08).

Insufficient motor torque.

• Assuming parameter settings are normal and that no overvoltage occurs when there is insufficient torque, it is likely

that the demand on the motor has exceeded the motor capacity.

• Use a larger motor.

Reaching the torque limit.

• Check the settings for the torque limit (L7-01 through L7-04).

• If the torque limit is enabled, deceleration might take longer than expected because the drive cannot output more

torque than the limit setting. Ensure the torque limit is set to a high enough value.

• Increase the torque limit setting.

• If multi-function analog input terminal A1, A2, or A3 is set to torque limit (H3-02, H3-10, or H3-06 equals 10, 11, 12,

or 15), ensure that the analog input levels are set to the correct levels.

• Ensure H3-02, H3-10, and H3-06 are set to the right levels.

• Ensure the analog input is set to the correct value (U1-13 to U1-15).

Load exceeded the internal torque limit determined by the drive

rated current.

Switch to a larger capacity drive.

Cause Possible Solutions

The timing for the brake to close and release is not set properly. Refer to Notes on Controlling the Brake when Using the Hoist Application Preset on page 117.

Insufficient DC Injection Braking. Increase the amount of DC Injection Braking (b2-02).

Cause Possible Solutions

Relay switching in the drive generates

excessive noise.

• Lower the carrier frequency (C6-02).

• Install a noise filter on the input side of drive input power.

• Install a noise filter on the output side of the drive.

• Place the wiring inside a metal conduit to shield it from switching noise.

• Ground the drive and motor properly.

• Separate the main circuit wiring and the control lines.

• Make sure wires and the motor have been properly grounded.

Cause Possible Solutions

Excessive leakage current trips RCM/RCD.

• Increase the RCM/RCD sensitivity or use RCM/RCD with a higher threshold.

• Lower the carrier frequency (C6-02).

• Reduce the length of the cable used between the drive and the motor.

• Install a noise filter or reactor on the output side of the drive. Set the carrier frequency to 2 kHz when connecting a reactor.

Cause Possible Solutions

The carrier frequency is at the resonant frequency of the connected

machinery.

Adjust the carrier frequency using parameters C6-02 through C6-05.

The drive output frequency is the same as the resonant frequency

of the connected machinery.

• Adjust the parameters used for the Jump frequency function (d3-01 through d3-04) to skip the problem-causing

bandwidth.

• Place the motor on a rubber pad to reduce vibration.

Cause Possible Solutions

Insufficient tuning.

Perform Auto-Tuning.

Refer to Motor Performance Fine-Tuning on page 326.

Gain is too low when using PID control. Refer to b5: PID Control on page 167 for details.

The frequency reference is assigned to an external source and the

signal is noisy.

• Ensure that noise is not affecting the signal lines.

• Separate main circuit wiring and control circuit wiring.

• Use twisted-pair cables or shielded wiring for the control circuit.

• Increase the analog input time filter constant (H3-13).

The cable between the drive and motor is too long.

• Perform Auto-Tuning.

• Reduce the length of the cable.

Loading...

Loading...