326 YASKAWA ELECTRIC SIEP C710616 27G YASKAWA AC Drive A1000 Technical Manual

6.2 Motor Performance Fine-Tuning

6.2 Motor Performance Fine-Tuning

This section offers helpful information for counteracting oscillation, hunting, or other problems that occur while

performing a trial run. Refer to the section below that corresponds to the motor control method used.

Note: This section describes parameters that are commonly edited and may be set incorrectly. Consult YASKAWA for more

information on detailed settings and fine-tuning the drive.

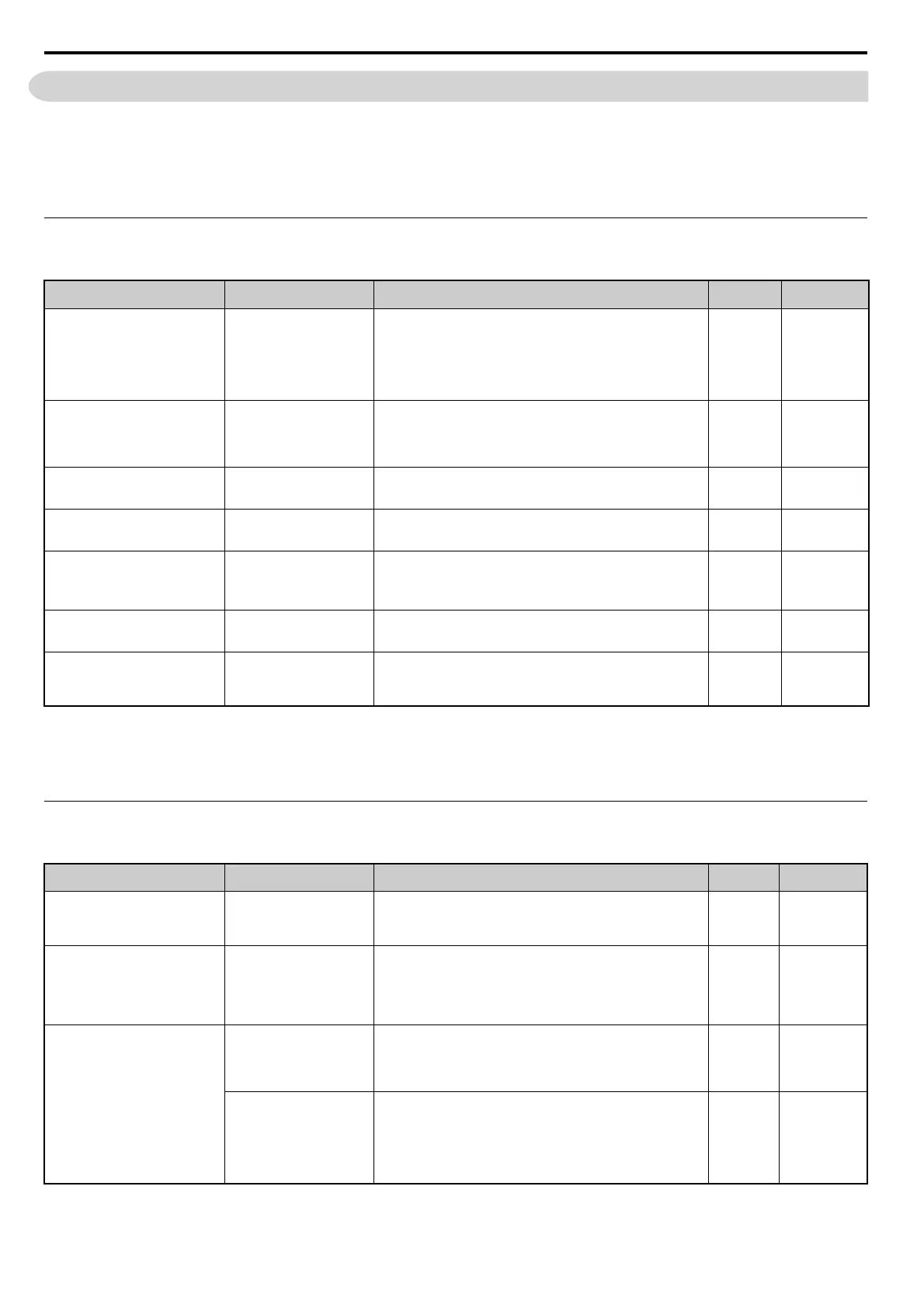

Fine-Tuning V/f Control and V/f Control with PG

Table 6.1 Parameters for Fine-Tuning Performance in V/f and V/f w/PG

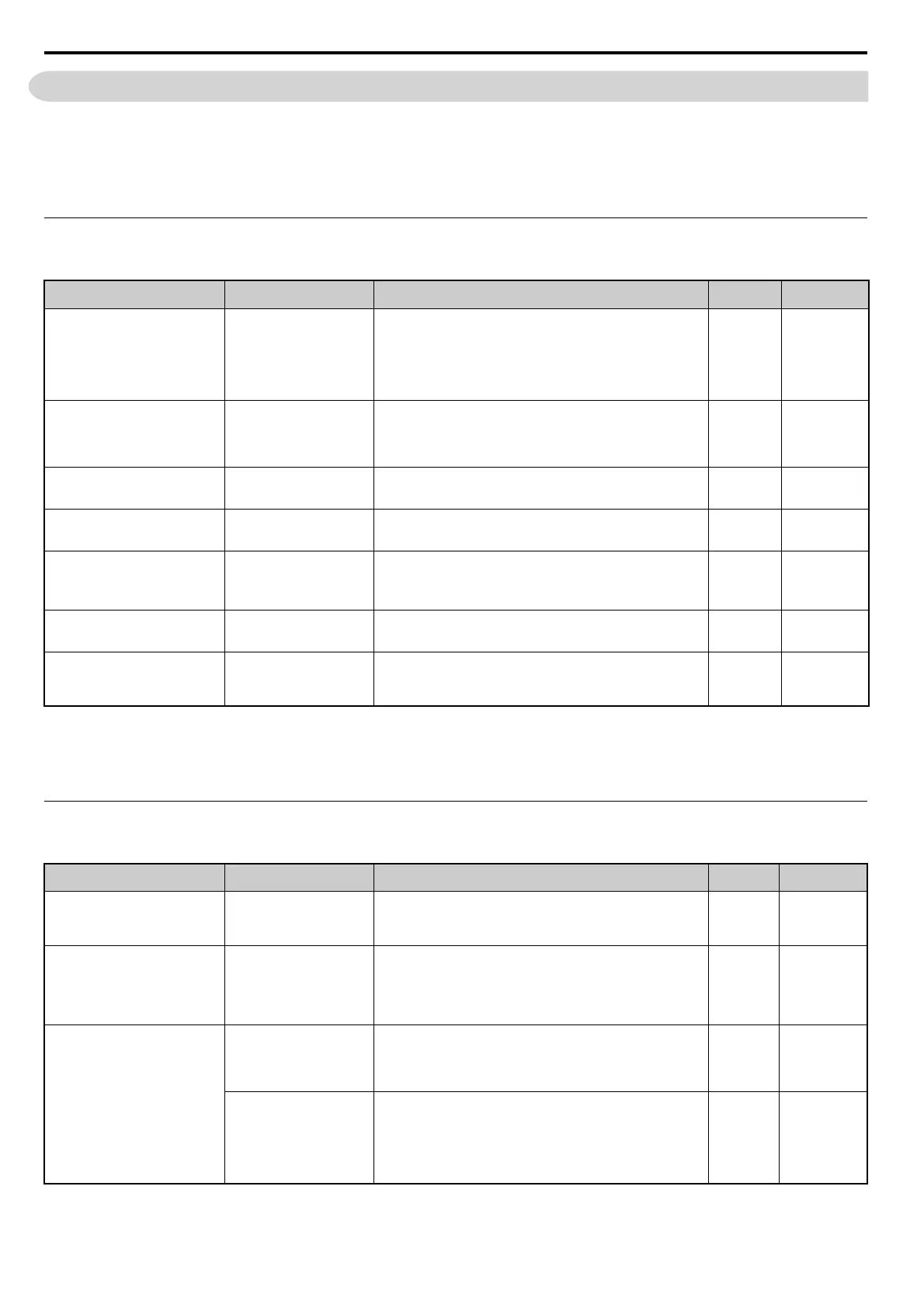

Fine-Tuning Open Loop Vector Control

Table 6.2 Parameters for Fine-Tuning Performance in OLV

Problem

<1> Default setting value is dependent on parameter A1-02, Control Method Selection, and o2-04, Drive Model Selection.

<2> Default settings change when the Control Method is changed (A1-02) or a different V/f pattern is selected using parameter E1-03.

<3> ASR in V/f Control with PG only controls the output frequency, and therefore does not allow the high gain settings possible when using Close

Loop Vector control.

<4> Refer to C5: Automatic Speed Regulator (ASR) on page 190 for details on Automatic Speed Regulator (ASR).

Parameter No. Corrective Action Default

Suggested

Setting

Motor hunting and oscillation at speeds

between 10 and 40 Hz

Hunting Prevention Gain

(n1-02)

• If insufficient motor torque relative to t

he size of the load causes hunting,

reduce the setting.

• When motor hunting and oscillation occu

r with a light load, increase the

setting.

• Lower this setting if hunting occurs when

using a motor with a relatively

low inductance, such as a high-frequency motor or a motor with a larger

frame size.

1.00 0.10 to 2.00

• Motor noise

• Motor hunting and oscillation at

spe

eds up to 40 Hz

Carrier Frequency Selection

(C6-02)

• If the motor noise is too loud, i

ncrease the carrier frequency.

• When motor hunting and oscillation occu

r at speeds up to 40 Hz, lower

the carrier frequency.

• The default setting for the carrier freq

uency depends on the drive

capacity (o2-04) and the Duty Selection (C6-01).

1 (2 kHz) 1 to max. setting

• Poor torque or speed response

• Motor hunting and oscillation

Torque Compensation Primary

De

lay Time

(C4-02)

• If motor torque and speed response are

too slow, decrease the setting.

• If motor hunting and oscillation occur, increase the setting.

200 ms

<1> 100 to 1000 ms

• Poor motor torque at speeds below 10

Hz

• Motor hunting and oscillation

Torque Compensation Gain

(C4-01)

• If motor torque is insufficient at speeds

below 10 Hz, increase the setting.

• If motor hunting and oscillation with a relativ

ely light load, decrease the

setting.

1.00 0.50 to 1.50

• Poor motor torque at low speeds

• Motor instability at motor start

Mid Output Voltage A (E1-08)

Minimum Output Voltage

(E1-10)

• If torque is insufficient at speeds below 10 Hz, increase the setting.

• If motor instability occurs at motor start, decrease the setting.

E1-08: 15.0 V

E1-10: 9.0 V

<2>

Default setting

±5 V

Note:

The recommended setting value is for 200 V class drives. Double

this value when using a 400 V class drive.

Poor speed precision (V/f control)

Slip Compensation Gain

(C3-01)

After setting the motor-rated current (E2-01), m

otor-rated slip (E2-02), and

motor no-load current (E2-03), adjust the slip compensation gain (C3-01).

0.0

(no slip

c

ompensation)

0.5 to 1.5

Poor speed precision (V/f control with

PG)

ASR Proportional Gain 1 (C5-01)

ASR Integral Time 1 (C5-02)

<3> <4>

Adjust the ASR proportional gain 1 (C5-01) and the ASR integral time 1

(C5-02).

C5-01: 0.20

C5-02: 0.200 s

Proportional gain

= 0.10 to 1.00

Integral time

= 0.100 to 2.000 s

Problem Parameter No. Corrective Action Default

Suggested

Setting

• Poor motor torque and speed

response

• Motor hunting and oscillation at

speeds b

etween 10 and 40 Hz

AFR Gain

(n2-01)

• If motor torque and speed response are

too slow, gradually decrease the

setting by 0.05.

• If motor hunting and oscillation occur

, gradually increase the setting by

0.05.

1.00 0.50 to 2.00

• Poor motor torque and speed

r

esponse

• Motor hunting and oscillation at

speeds b

etween 10 and 40 Hz

AFR Time Constant 1

(n2-02)

• To improve motor torque speed response,

gradually reduce this setting by

10 ms and check the performance.

• If motor hunting and oscillation occur as

a result of load inertia, gradually

increase the setting by 50 ms and check the performance.

Note: Ens

ure that n2-02 n2-03. When changing n2-02, set C4-02 (Torque

Compensation Primary Delay Time Constant 1) accordingly.

50 ms 50 to 2000 ms

Overvoltage trips when acce

lerating,

decelerating, or during sudden speed or

load changes.

AFR Time Constant 2

(n2-03)

• If overvoltage occur, graduall

y increase this setting by 50 ms.

• If response is slow, gradually reduce

this setting by 10 ms.

Note: Ens

ure that n2-02 n2-03. When making adjustments to n2-03,

increase the value of C4-06 (Torque Compensation Primary Delay Time 2)

proportionally.

750 ms 750 to 2000 ms

Torque Compensation Primary

Delay Time Constant 2 (C4-06)

• If overvoltage trips occur, gradually increase this setting by 10 ms and

chec

k the performance.

• If response is slow, gradually reduce thi

s setting by 2 ms and check the

performance.

Note: Ensure t

hat C4-02 C4-06. When changing C4-06 (Torque

Compensation Primary Delay Time Constant 2), increase the value of n2-03

proportionally.

150 ms 150 to 750 ms

Loading...

Loading...