6.2 Motor Performance Fine-Tuning

YASKAWA ELECTRIC SIEP C710616 27G YASKAWA AC Drive A1000 Technical Manual 327

When using OLV, leave the torque compensation gain (C4-01) at its default setting of 1.00.

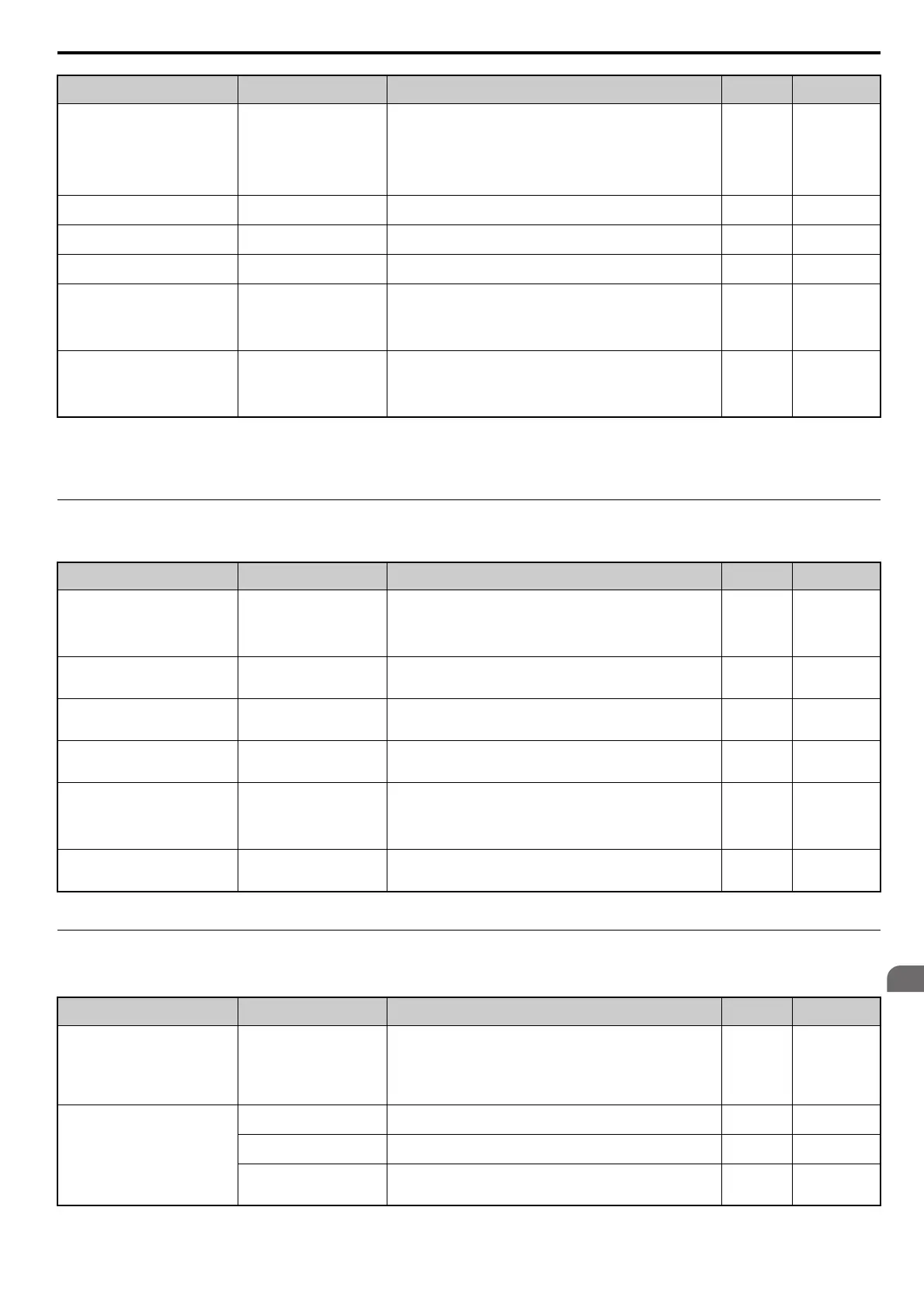

Fine-Tuning Closed Loop Vector Control

Table 6.3 Parameters for Fine-Tuning the Performance in CLV

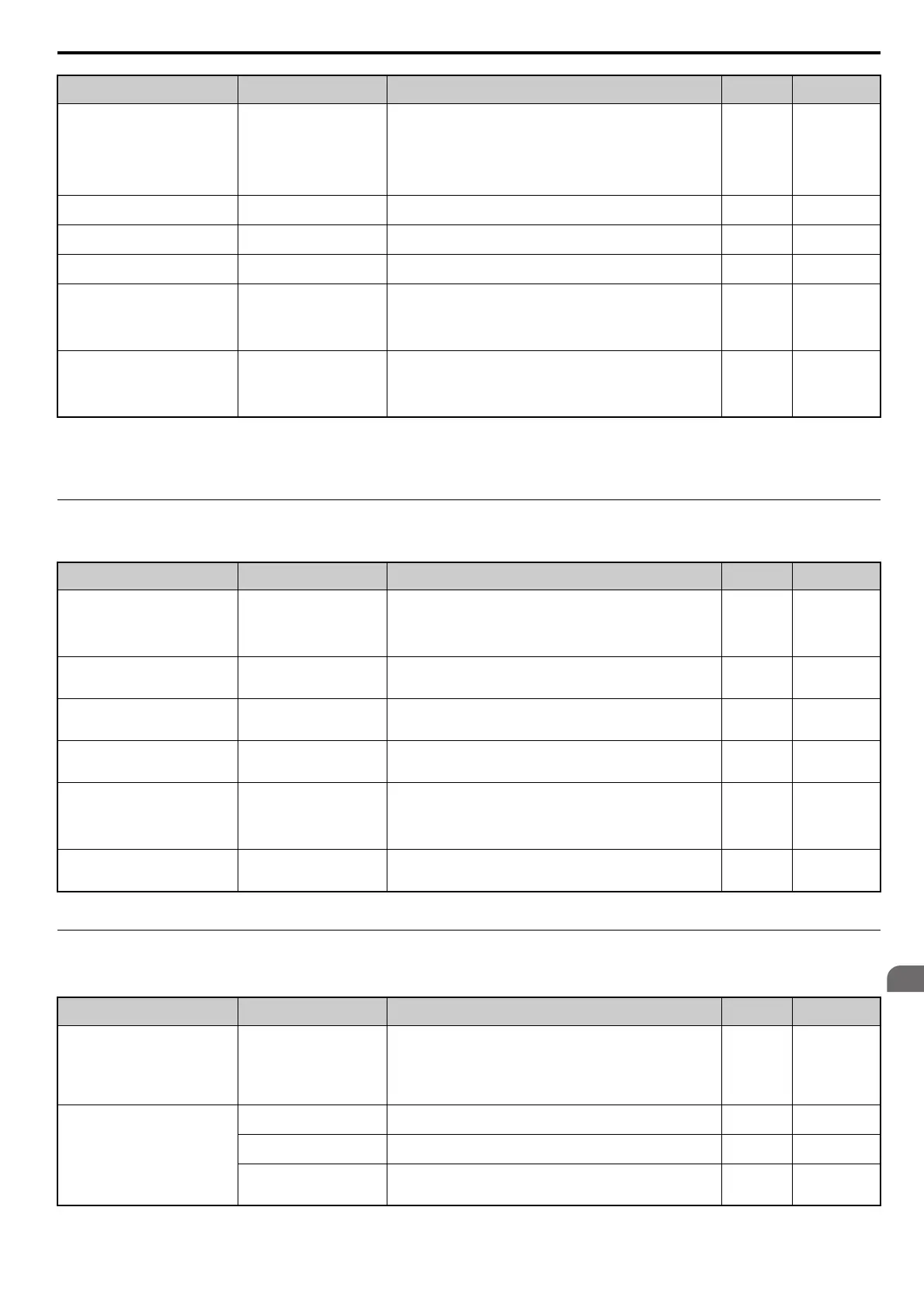

Fine-Tuning Open Loop Vector Control for PM Motors

Table 6.4 Parameters for Fine-Tuning Performance in OLV/PM

• Poor motor torque and speed

response

• Motor hunting and oscillation

Torque Compensation Primary

D

elay Time Constant 1 (C4-02)

• To improve motor torque speed response, gradual

ly reduce this setting by

2 ms and check the performance.

• If motor hunting and oscillation occur, graduall

y increase this setting by

10 ms.

Note: Ens

ure that C4-02 C4-06. When making adjustments to C4-02,

increase the Speed Feedback Detection Control (AFR) Time Constant1

(n2-02) proportionally.

20 ms

<1> 20 to 100 ms <1>

Poor speed response and stability

Slip Compensation Primary

Delay Time Constant (C3-02)

• If response is slow, gradually decrease the setting by 10 ms.

• If speed is unstable, gradually increase the setting by 10 ms.

200 ms <2> 100 to 500 ms

Poor speed precision Slip Compensation Gain (C3-01)

• If speed is too slow, gradually increase the setting by 0.1 ms.

• If speed is too fast, gradually decrease t

he setting by 0.1 ms.

1.0

<2> 0.5 to 1.5

Poor speed precision during

r

egenerative operation

Slip Compensation Selection

During Regeneration (C3-04)

Enable slip compensation during regeneration by setting parameter C3-04

= 1.

0 1

• Motor noise

• Motor hunting and oscillation occur

at

speeds below 10 Hz

Carrier Frequency Selectio

n

(C6-02)

• If there is too much motor noise, t

he carrier frequency is too low.

• If motor hunting and oscillation occur at low speeds, reduce the carrier

f

requency.

Note: The default

setting for the carrier frequency depends on the drive

capacity (o2-04) and Duty Selection (C6-01).

1 (2 kHz) 0 to max. setting

• Poor motor torque at low speeds

• Poor speed response

• Motor instability at start

Mid Output Voltage A (E1-08)

Minimum Output Voltage

(E1-10

)

• If motor torque and speed response are too slow, increase the setting.

• If the motor exhibits excessive instability at start-up, reduce the setting.

Note: The default

value is for 200 V class units. Double this value when

using a 400 V class drive. When working with a relatively light load,

increasing this value too much can result in overtorque.

E1-08: 11.0 V

<2>

E1-10: 2.0 V

<2>

Default setting

±2 V

<1> Default setting value is dependent on parameter A1-02, Control Method Selection, and o2-04, Drive Model Selection.

<2> Default settings change when the Control Method is changed (A1-02) or a different V/f pattern is selected using parameter E1-03.

Problem

<1> Refer to C5: Automatic Speed Regulator (ASR) on page 190 for details on Automatic Speed Regulator (ASR).

Parameter No. Corrective Action Default

Suggested

Setting

• Poor torque or speed response

• Motor hunting and oscillation

ASR Proportional Gain 1

(C5-01)

ASR Proportional Gain 2

(C5-03)

<1>

• If motor torque and speed response are too slow, gradually increase the

ASR gain setting by 5.

• If motor hunting and oscillation

occur, decrease the setting.

• Parameter C5-03 needs to be adjusted only if C5-05 > 0.

• Perform ASR Auto-Tuning if possible

20.00 10.00 to 50.00

• Poor torque or speed response

• Motor hunting and oscillation

ASR Integral Time 1 (C5-02)

ASR Integral Time 2 (C5-04)

<1>

• If motor torque and speed response are too slow, decrease the setting.

• If motor hunting and oscillation occur, increase the setting.

• Parameter C5-04 needs to be adjusted only if C5-05 > 0.

0.500 s 0.300 to 1.000 s

Trouble maintaining the ASR

proport

ional gain or the integral time at

the low or high end of the speed range

ASR Gain Switching Frequency

(C

5-07)

<1>

Have the drive switch between two different ASR proportional gain and

integral time settings based on the output frequency.

0.0 Hz

0.0 to max output

frequency

Motor hunting and oscillation

ASR Primary Delay Time

Co

nstant (C5-06)

<1>

• If motor torque and speed response are too slow, gradually decrease the

setting by 0.01.

• If the load is less rigid and subject to oscillation, increase this setting.

0.004 s 0.004 to 0.020 s

• Motor noise

• Control motor hunting and oscillation

occur at speeds below 3 Hz.

Carrier Frequency Selection

(C6-02)

• If there is too much motor noise, t

he carrier frequency is too low.

• If motor hunting and oscillation occur at low speeds, reduce the carrier

f

requency.

Note: The default

setting for the carrier frequency depends on the drive

capacity (o2-04) and Drive Duty Selection (C6-01).

1

2.0 kHz to the max.

se

tting

Overshoot or undershoot when the

s

peed changes with high inertia load.

Feed Forward Control (n5-01)

Inertia Tuning (T1-01 = 8)

Enable Feed Forward by setting parameter n5-01 = 1 and perform Inertia

Tuning. If Inertia Tuning is not possible, set parameters C5-17, C5-18, and

n5-03 manually.

0 1

Problem Parameter No. Corrective Action Default

Suggested

Setting

Motor performance not as desired

Motor parameters

(E1-, E5-)

• Check the settings for base and maximum frequency in the E1-

param

eters

• Check E5- parameters and make sure all motor data has been set

c

orrectly. Be careful not to enter line to line data where single-phase data

is required, and vice versa.

• Perform Auto-Tuning.

– –

Poor motor torque and speed response

Load Inertia Ratio (n8-55) Adjust parameter n8-55 to meet the load inertia ratio of the machine. 0

Close to the actual

l

oad inertia ratio

Speed Feedback Detection Gain

(f

or PM Motors) (n8-45)

Decrease the speed feedback detection gain (n8-45). 0.8

Decrease in

decrements of 0.05

Torque Compensation (C4-01)

Enable torque compensation.

Note: Set

ting this value too high can cause overcompensation and motor

oscillation.

0 1

Problem Parameter No. Corrective Action Default

Suggested

Setting

Loading...

Loading...