6.4 Fault Detection

348 YASKAWA ELECTRIC SIEP C710616 27G YASKAWA AC Drive A1000 Technical Manual

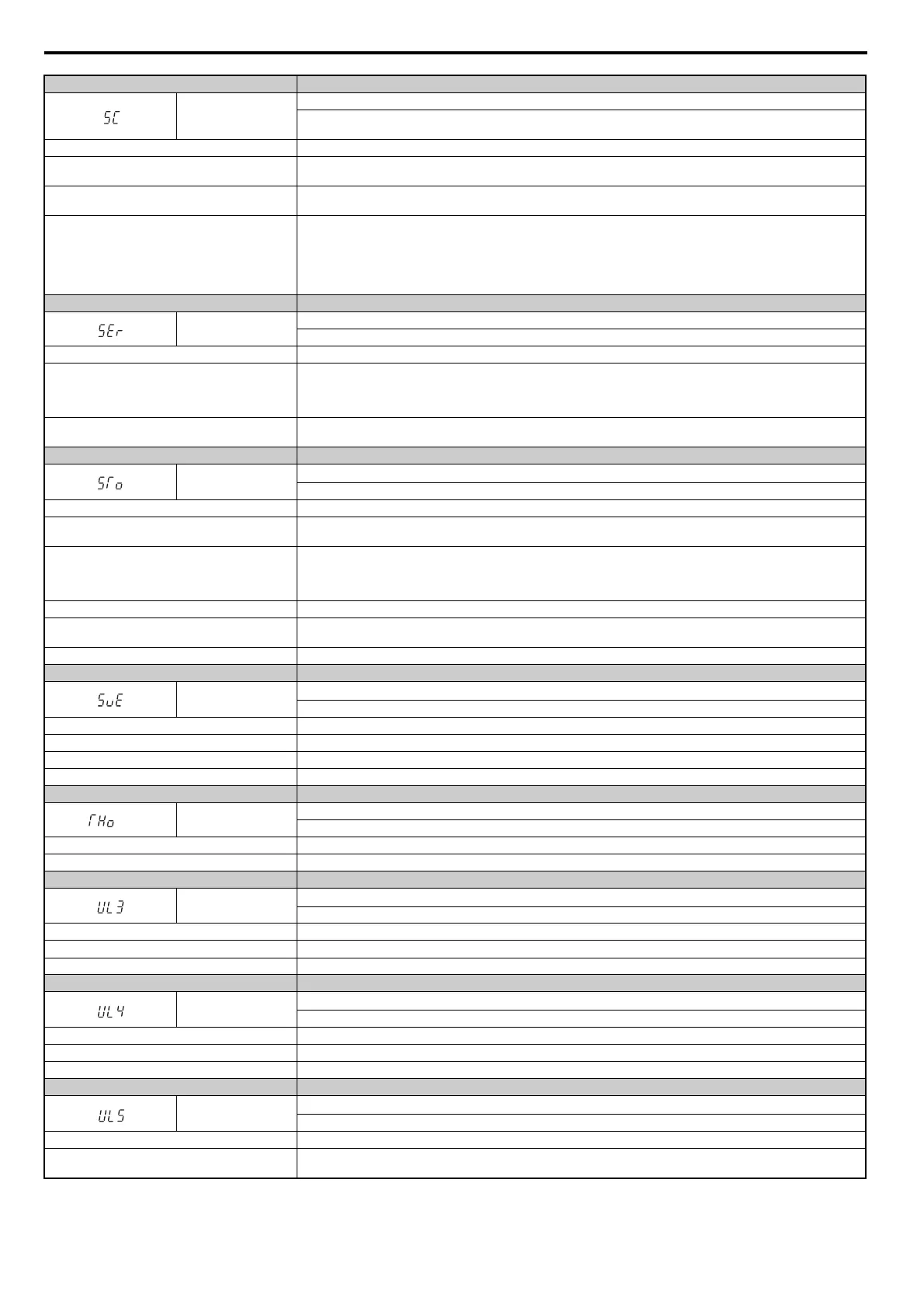

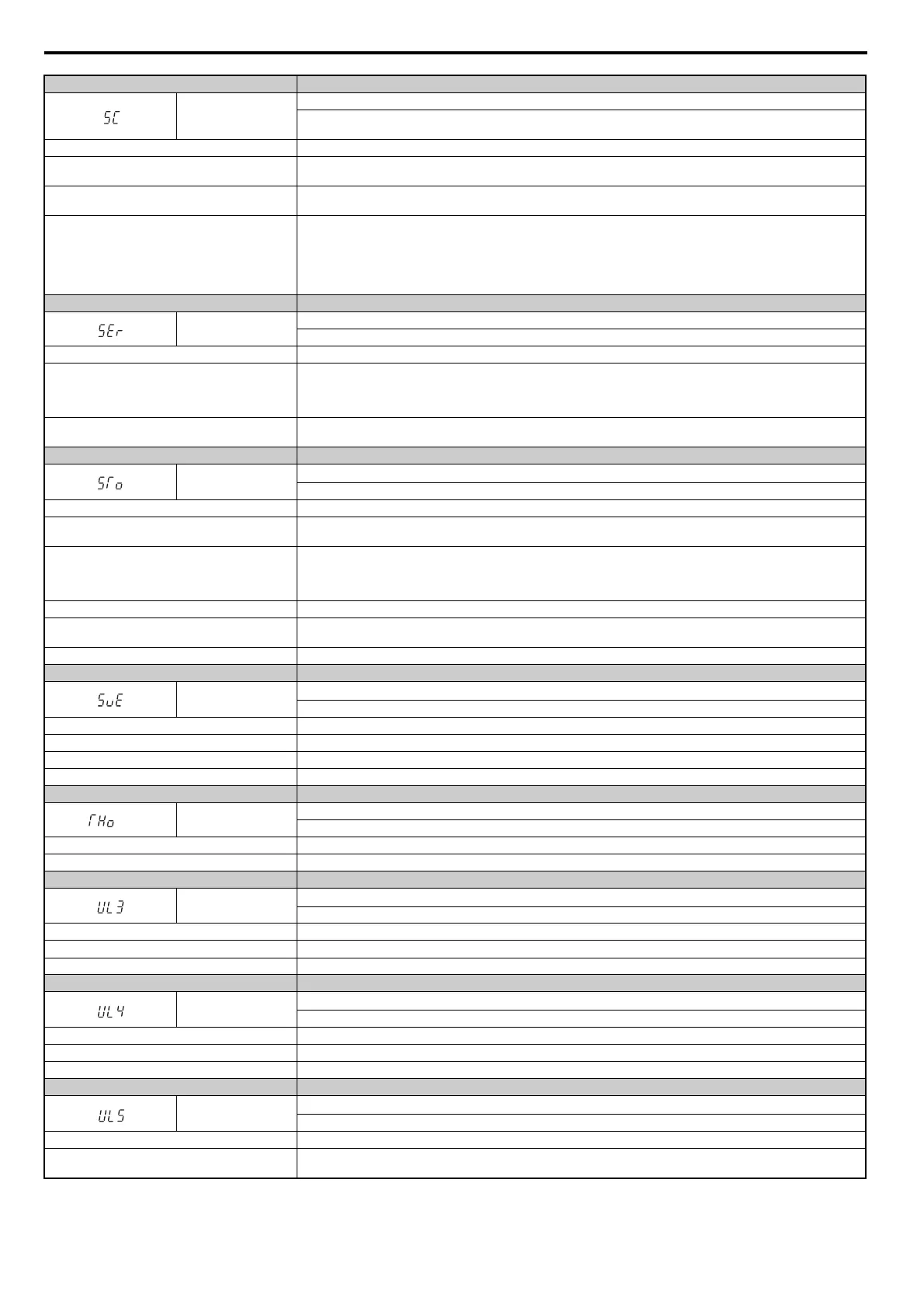

Digital Operator Display Fault Name

SC

Output Short-Circuit or IGBT Fault

Sho

rt Circuit or Ground Fault is detected

Note: Fault reset will not be received to prevent a short-circuit of the internal circuitry caused by the IGBP fault.

Cause Possible Solution

Motor has been damaged from

overheat or the motor

insulation has been weakened.

Check the motor insulation resistance and replace the motor if continuity is detected.

The cable is damaged and is coming into contact with

something causing a short-circuit.

Check the motor power cable. Repair any short-circuits.

Hardware fault.

A short-circuit or grounding fault on the drive outp

ut side has damaged the output transistors.

Make sure drive output is not shorted as follows:

B1

U, V, W

– (negative)

U, V, W

The above short-circuit will dam

age the output transistors.

Contact your YASKAWA representative or our sales offices for assistance.

Digital Operator Display Fault Name

SEr

Too Many Speed Search Restarts

Th

e number of Speed Search restarts exceeded the number set to b3-19.

Cause Possible Solution

Speed Search parameters are set to the wrong values.

• Reduce the detection compensation gai

n during Speed Search (b3-10).

• Increase the current level when at

tempting Speed Search (b3-17).

• Increase the detection time duri

ng Speed Search (b3-18).

• Repeat Auto-Tuning.

The motor is coasting in the opposite direction of the

Run command.

Enable Bi-Directional Speed Search (b3-14 = 1).

Digital Operator Display Fault Name

STo

Motor Pull Out or Step Out Detection

M

otor pull out or step out has occurred. Motor has exceeded its pull-out torque.

Cause Possible Solution

The wrong motor code is set (YASKAWA motors only).

• Enter the correct motor code for the PM being used into E5-01.

• For special-purpose motors, enter the correct data to all E5 parameters according to the test report provided for the motor.

Load is too heavy.

• Increase the load inertia for PM motor (n8-55

).

• Increase the pull-in current d

uring accel/decel (n8-51).

• Reduce the load.

• Increase the motor or drive capacity.

Load inertia is too heavy. Increase the

load inertia for PM motor (n8-55).

Acceleration and deceleration times are too short.

• Increase the acceleration and decelerati

on times (C1-01 through C1-08).

• Increase the S-curve acceleration and deceleration times (C2-01).

Speed response is too slow. Increase the load inertia for PM motor (n8-55).

Digital Operator Display Fault Name

SvE

Zero Servo Fault

Pos

ition deviation during zero servo.

Cause Possible Solution

Torque limit is set too low. Set the torque limit to an appropriate value using parameters L7-01 to L7-04.

Excessive load torque. Reduce the amount of load torque.

Electrical signal interference along PG encoder wiring. Check the PG signal for electrical signal interference.

Digital Operator Display Fault Name

<2>

THo

Thermistor Disconnect

The

thermistor used to detect motor temperature has become disconnected.

Cause Possible Solution

The motor thermistor is not connected properly. Check the wiring for the thermistor.

Digital Operator Display Fault Name

UL3

Undertorque Detection 1

Th

e current has fallen below the minimum value set for torque detection (L6-02) for longer than the allowable time (L6-03).

Cause Possible Solution

Parameter settings are not appropriate for the load. Check the settings of parameters L6-02 and L6-03.

There is a fault on the machine side. Check the load for any problems.

Digital Operator Display Fault Name

UL4

Undertorque Detection 2

Th

e current has fallen below the minimum value set for torque detection (L6-05) for longer than the allowable time (L6-06).

Cause Possible Solution

Parameter settings are not appropriate for the load. Check the settings of parameters L6-05 and L6-06.

There is a fault on the machine side. Check the load for any problems.

Digital Operator Display Fault Name

UL5

Mechanical Weakening Detection 2

Th

e operation conditions matched the conditions set to L6-08.

Cause Possible Solution

Undertorque was detected and m

atched the conditions

for mechanical loss detection set to L6-08.

Check the load side for any problems.

Loading...

Loading...