8 System Setup

DX100 8.4 ARM Control

8-43

8.4.3 Tool Load Information Setting

8.4.3.1 Tool Load Information

Tool load information includes weight, a center of gravity position, and

moment of inertia at the center of gravity of the tool installed at the flange.

These are registered in the tool file.

8.4.3.2 How to Calculate Tool Load Information

Weight: W (Unit: kg)

The total weight of the installing tool is set.

It is not required to set a correct value, however, it is recommended to set

a value slightly larger than the actual load. (Round up the value with each

fraction between 0.5 to 1 kg for small and medium size manipulator, and 1

to 5 kgs for large manipulator.)

CAUTION

• Set the tool load information correctly.

The speed reducer longevity might decrease or the alarm might occur

when the tool load information is not set correctly.

• Confirm the operation path of robot of each job which uses the tool

file after the tool load information is changed.

Set the tool load information before teaching the job after the tool is

installed.

Confirm the operation path of each job which uses the tool file when the

tool load information should be modified after teaching.

Modifying the tool load information may slightly change the operation

path. To avoid injury or damage to machinery caused by collision

between tool and positioner, make sure to check the operation path

before executing a job.

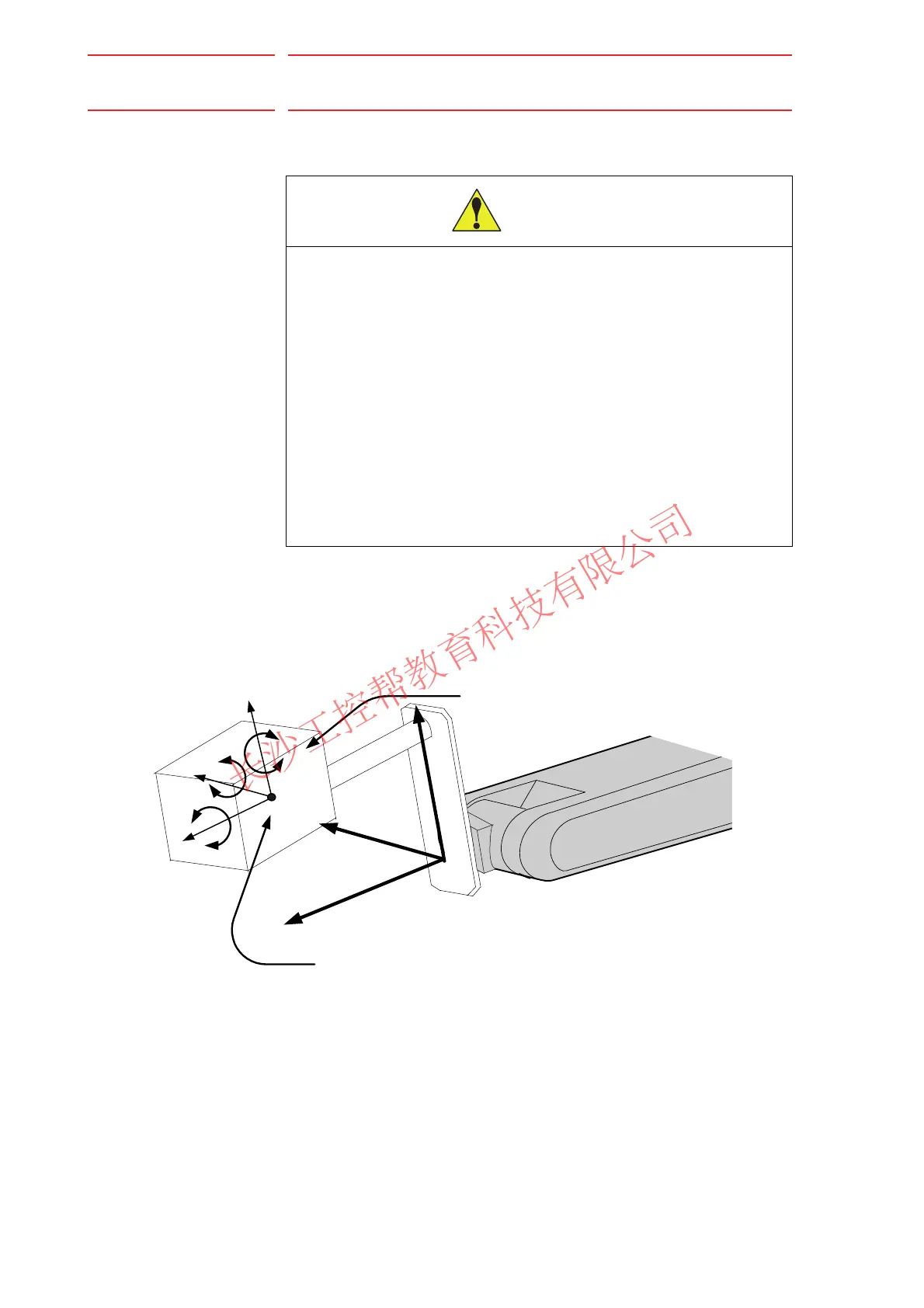

* Flange Coodinates

XF: It is a direction right above when T axis

is 0 pulse position and the flange surface

of the manipulator turned to the front.

YF: Y axis led by XF,ZF

ZF: Perpendicular direction from flange surface

XF

ZF

YF

XF'

ZF'

YF'

Center of Gravity Position

( Xg, Yg, Zg )

Iy

Iz

Ix

Moment of inertia around the Center of Gravity

Ix, Iy, Iz

Weight:W

Loading...

Loading...