119

Maintenance and Care

D

D

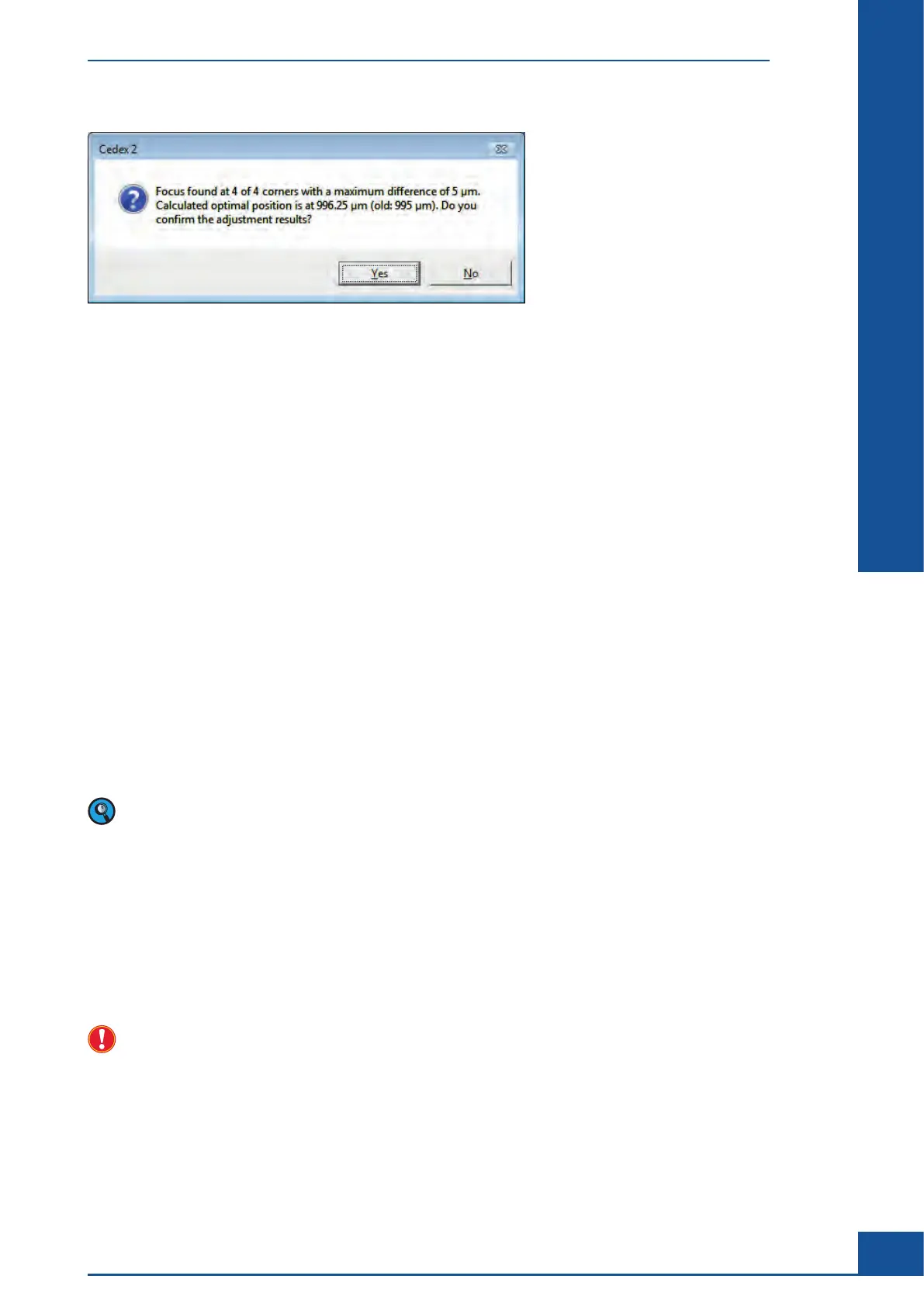

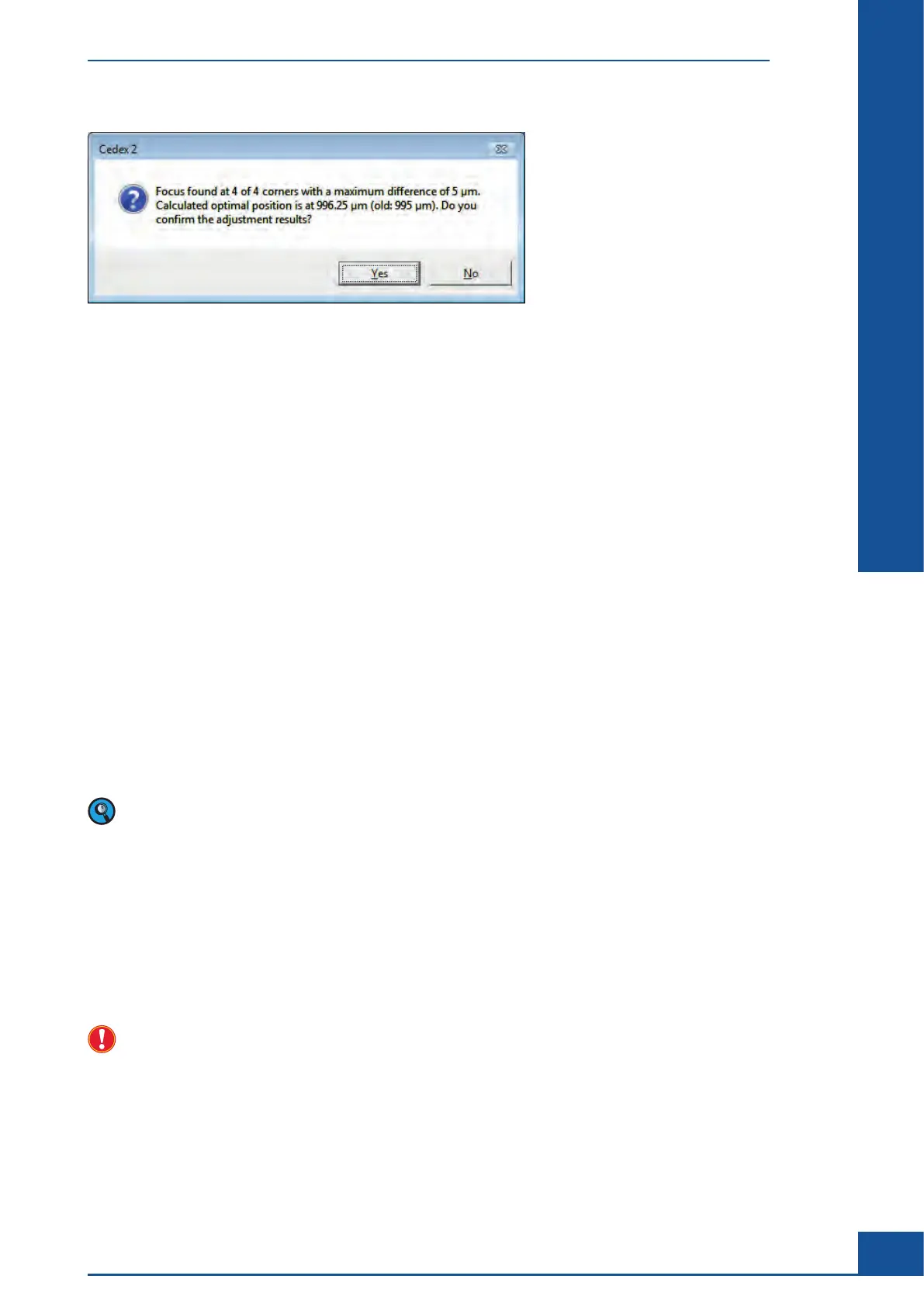

Figure 39: The Automatic Adjustment and Alignment Verification dialog box after adjustment, continued

The automatic adjustment and verification of alignment is carried out in several steps. First, water is pumped

into the flow chamber and a white balance is carried out. The Cedex Calibration Beads are then injected into

the flow chamber. Focus finding occurs after sedimentation. An automatic cleaning of the flow chamber and

the capillaries, as well as a new white balance, is done after focus adjustment. The focus adjustment’s time-

progression is displayed as an estimated value in the form of a blue progression bar.

Scans are carried out for every focus position. The images of the four corner areas are analyzed and these focus

values displayed in a diagram (see Figure 39). Focus positions are shown on the x-axis and focus quality on the

y-axis. A measurement can only deliver optimal results if the flow chamber is scanned at one level. This means

that the corner areas must have the same focus level.

The result appears on the monitor as a message box once the focus adjustment is finished (see Figure 39). Verify

that the different positions of the flow chamber have the same focus position by checking against the conditions

explained below, and confirm your approval with Ye s .

The focus position automatically set for the four corner areas (optimal position) must lie between 850 and

1250. Otherwise, an authorized Roche Service representative must re-adjust the Cedex HiRes Analyzer. Another

important value is the allowed maximum difference between the optimal focus values of the four corner areas.

The focus difference must be between ≥ 0 and ≤ 20. Otherwise, an authorized Roche Service representative must

re-adjust the Cedex HiRes Analyzer.

The Automatic Adjustment and Alignment Report can be printed out via the PRINT REPORT button. The

report shows a diagram (Focus Chart) with four curve progressions to the focus position.

The quality of the automatic adjustment and verification of alignment depends on the pre-adjustment of the

flow chamber and an even concentration of the focus beads in all of the pictures of the 4 corners. In order to

check that these conditions have been fulfilled, the following must be verified:

c

No edges are visible in the 4 pictures of the corners of the flow chamber.

c The pictures are not out of focus.

c All of the pictures have an even distribution of beads with at least 50 beads in every picture.

c The focus curves of all 4 corners have two clear maximums with one clear, marked minimum in the middle.

If any one of these conditions is not fulfilled, the results of the automatic adjustment should not be used.

Should striped shadows or lines appear on the images when running measurements, a new automatic

adjustment needs to be run as poor image quality can affect the results of the measurement.

Automatic Adjustment and Alignment Verification

Loading...

Loading...