CONTROLS

1001 DFB

Drilling & Sawing Line

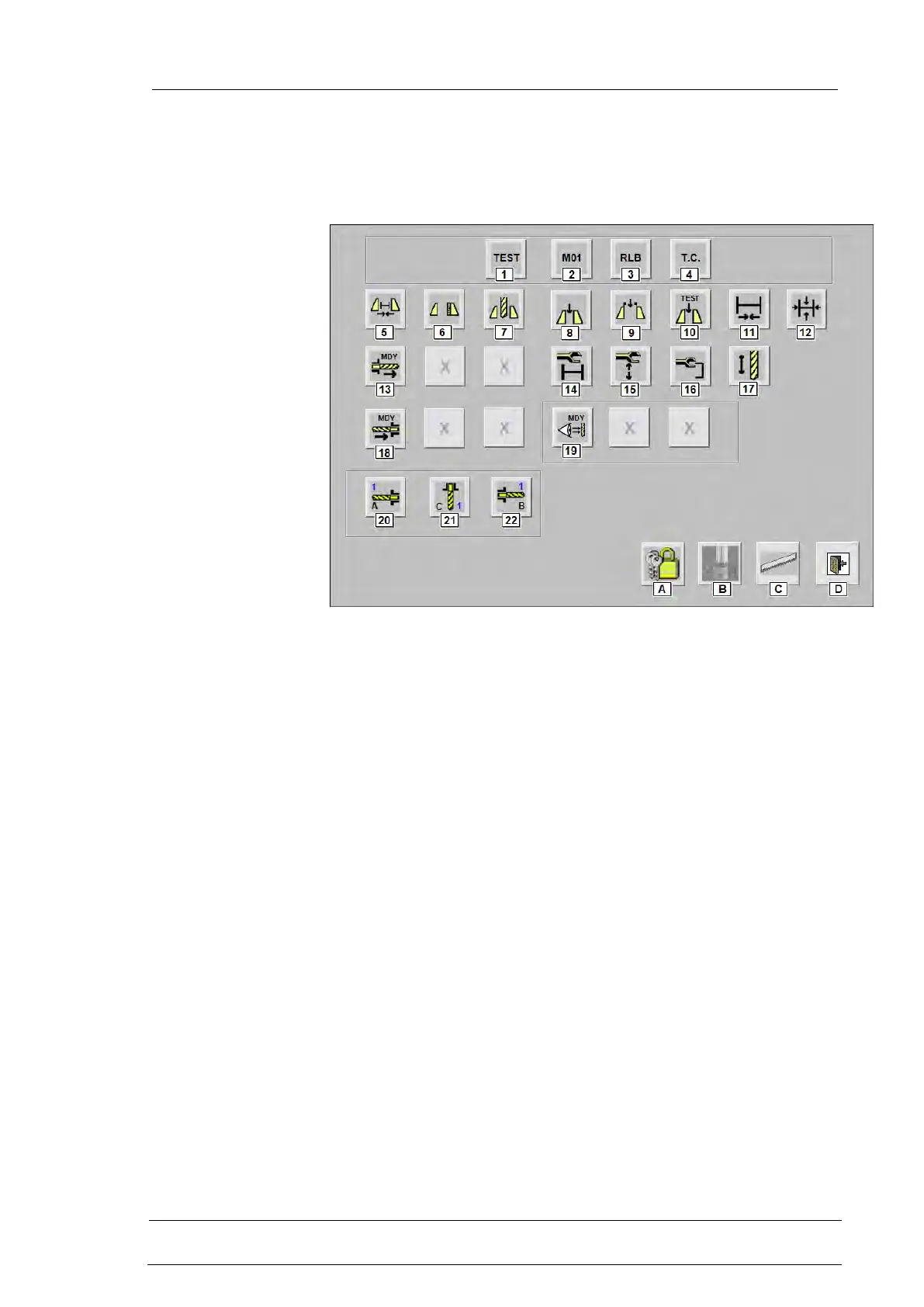

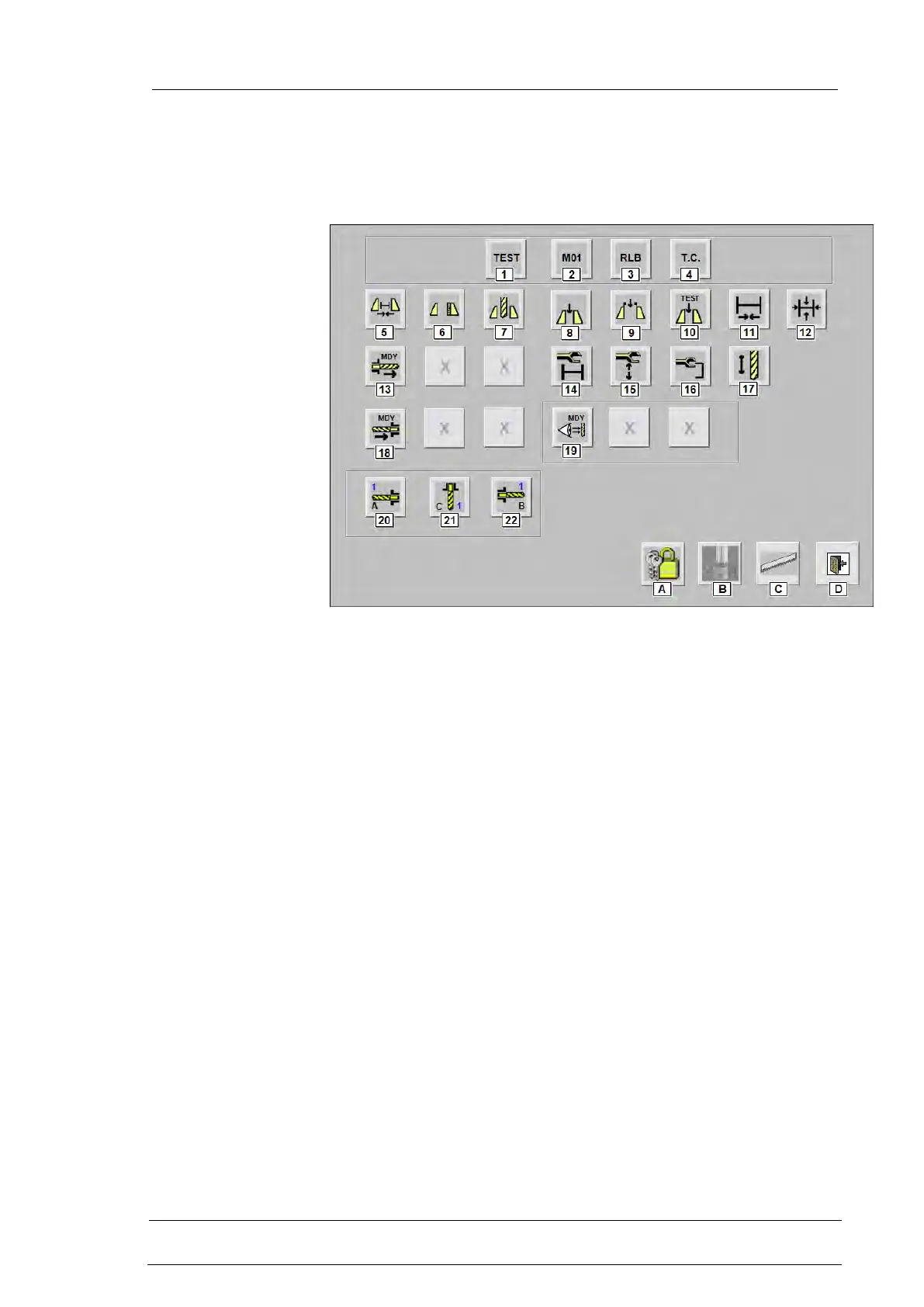

CNC push button control station – Drilling Unit

1. TEST It is used to simulate a no-load program, without any material

on the machine

2. M01 - If activated, the system executes the program and arrests the

working operations every time the command M01 is present

(programmed stop)

3. RLB It qualifies the true length pick-up of the bar to be processed

4. T.C. When the machine is not fitted with the Tool Change

(optional), it is used to position the drill head to the preset

coordinate for the tools change. If the marking unit (optional) is

present, it used to include the marking body and enable the manual

adjustment of the gaugeline

5. It qualifies the “rolls type vice”: when the carriage moves, the vice

keeps on closed on the section

6. It qualifies the use of the vice extension when processing of min.

size sections is required

7. It qualifies the min. C axis extended cycle

8. It qualifies the vertical clamping of the vice in AUTOMATIC

mode

9. It qualifies the vertical clamping extension of the vice. It enables to

control possible collisions.

10. It qualifies the vices vertical hold downs stand-by descent

Loading...

Loading...