Drilling only: distance from material surface in which the speed of item 15 becomes the

one specified at item 04 (see “Tables” field 12)

Drilling only: value (percentage) of the current threshold of the tool forward motor; if this

value is exceeded, a message like “motor under stress” is displayed

The operator can use the “+” and “-“ keys of the PC keyboard or directly touch the

screen to change the forward speed by steps of 10%.

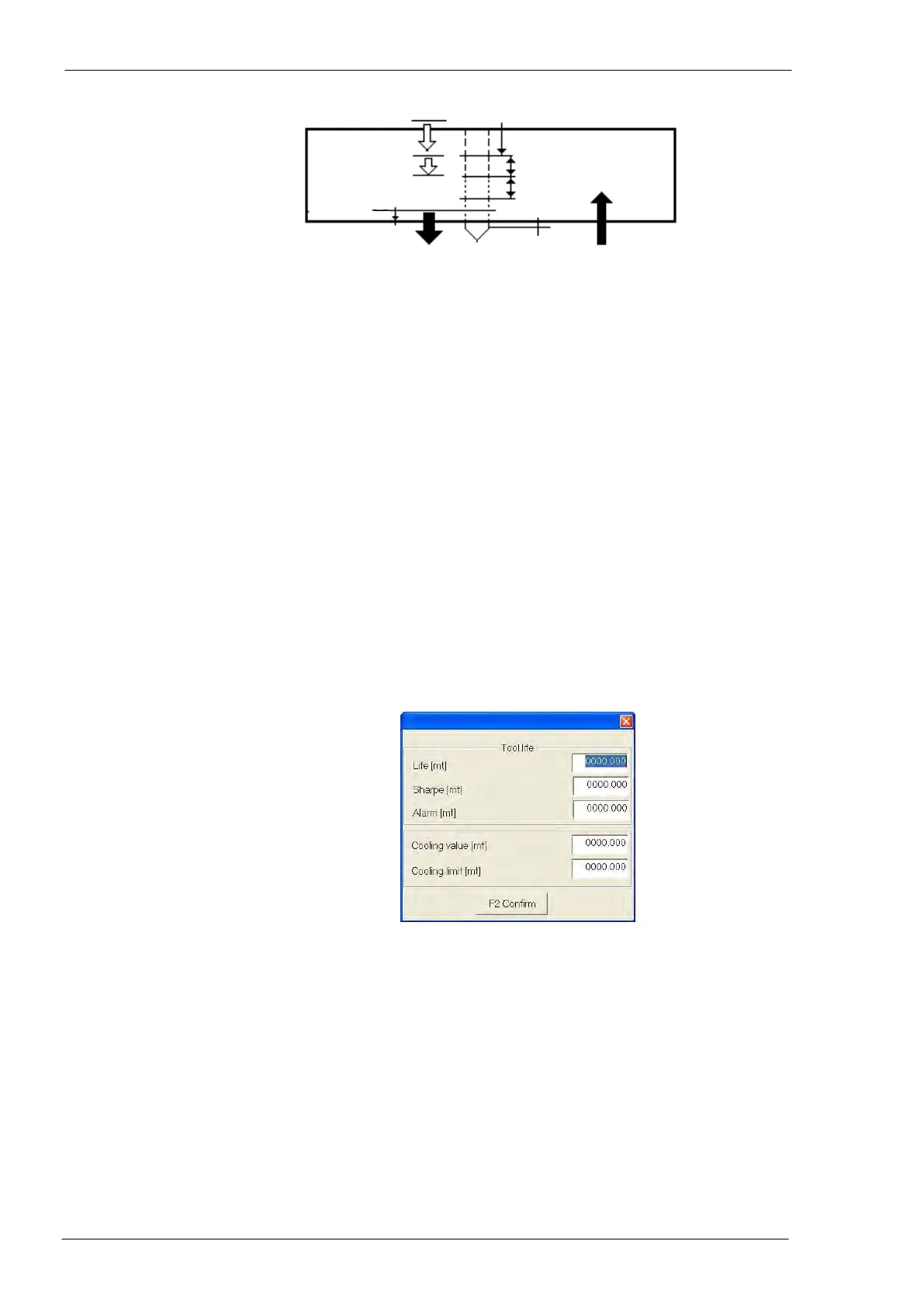

Pressing this push-button, a window is displayed where it is possible to define

the maximum working life of the selected tool.

Field “Life”: display the amount of thickness drilled by the selected tool from its

first insertion in the setup of the machine.

Field “Sharpe”: when the tool reaches the value here set, the CNC software

generates a message for the operator asking for tool sharpening.

Field “Alarm”: when the tool reaches the value here set, the CNC software

generates a message for the operator asking for tool replacement.

Field “Cooling value”: amount of thickness drilled by the selected tool from its

last insertion in the spindle.

Field “Cooling limit”: when the tool reaches the value here set, the CNC auto-

matically replaces the tool by a similar one with same diameter present in the

tool magazine.

To alternate tools with same diameter during the program in process, it is

necessary to select the option “Multiple diameters” in the “Execution parame-

ters” window (see Execution parameters - reference 08, page 77).

Loading...

Loading...