Model 1001 DFB Programming and operating manual

FICEP S.p.A. 45

Pocketing speed (see “Tables” field 18)

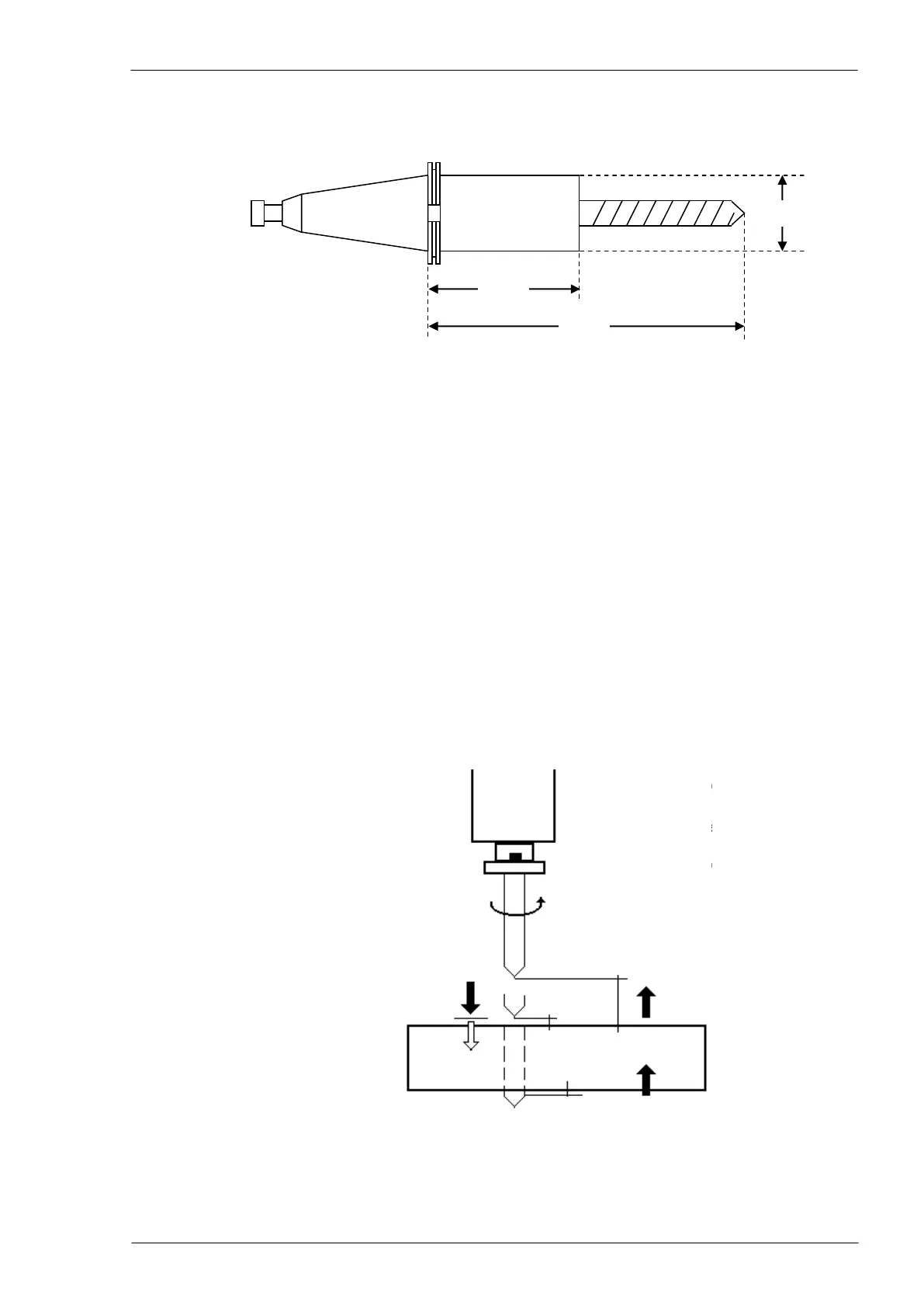

Tool length (LUT – see following picture)

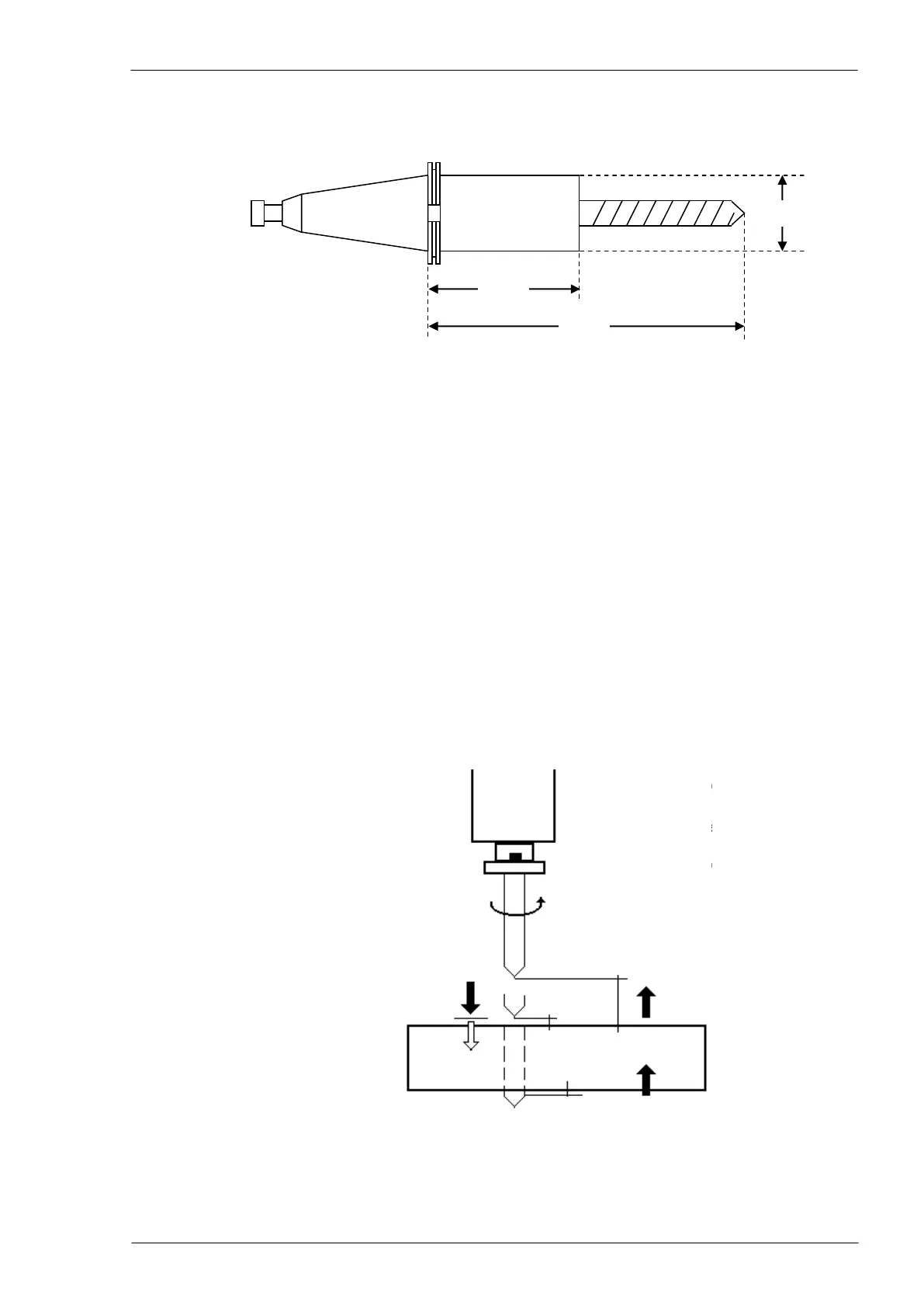

Distance from material to be reached by the tool before the positioning for the subse-

quent operation.

Distance from material to be reached by the tool before where the spindle change from

fast approach speed to spindle forward speed entering the material (04)

End of hole coordinate (out of material) where the spindle reverses the movement.

Drilling: real end of hole coordinate automatically calculated by CNC according to

the grinding angle (17)

Milling: coordinate where the spindle starts the contouring movement

Pocketing: real coordinate of working depth

This value is negative.

Drilling: First stop coordinate of the tool forward to break the chip

Pocketing: Tool positioning coordinate inside the material to execute the first pass

This value is negative.

Drilling: Incremental step for subsequent stops to break the chip

Pocketing: Incremental step for subsequent passes

This value is positive because it represents an increment in the same direction.

Only for drilling: at this coordinate the CNC increase the forward speed to break the ma-

terial. This value is negative because it is calculated from the opposite side re-

spect to the tool.

Loading...

Loading...