Programming and operating manual Model 1001 DFB

78 FICEP S.p.A.

- Cut-to-length piece circumscribed: like previous “piece cut to length” but with

possibility of initial and final angled cuts

N.B. this option is not available to carry out a nested job; it is valid only to

achieve single pieces

- Other possible choices: not used

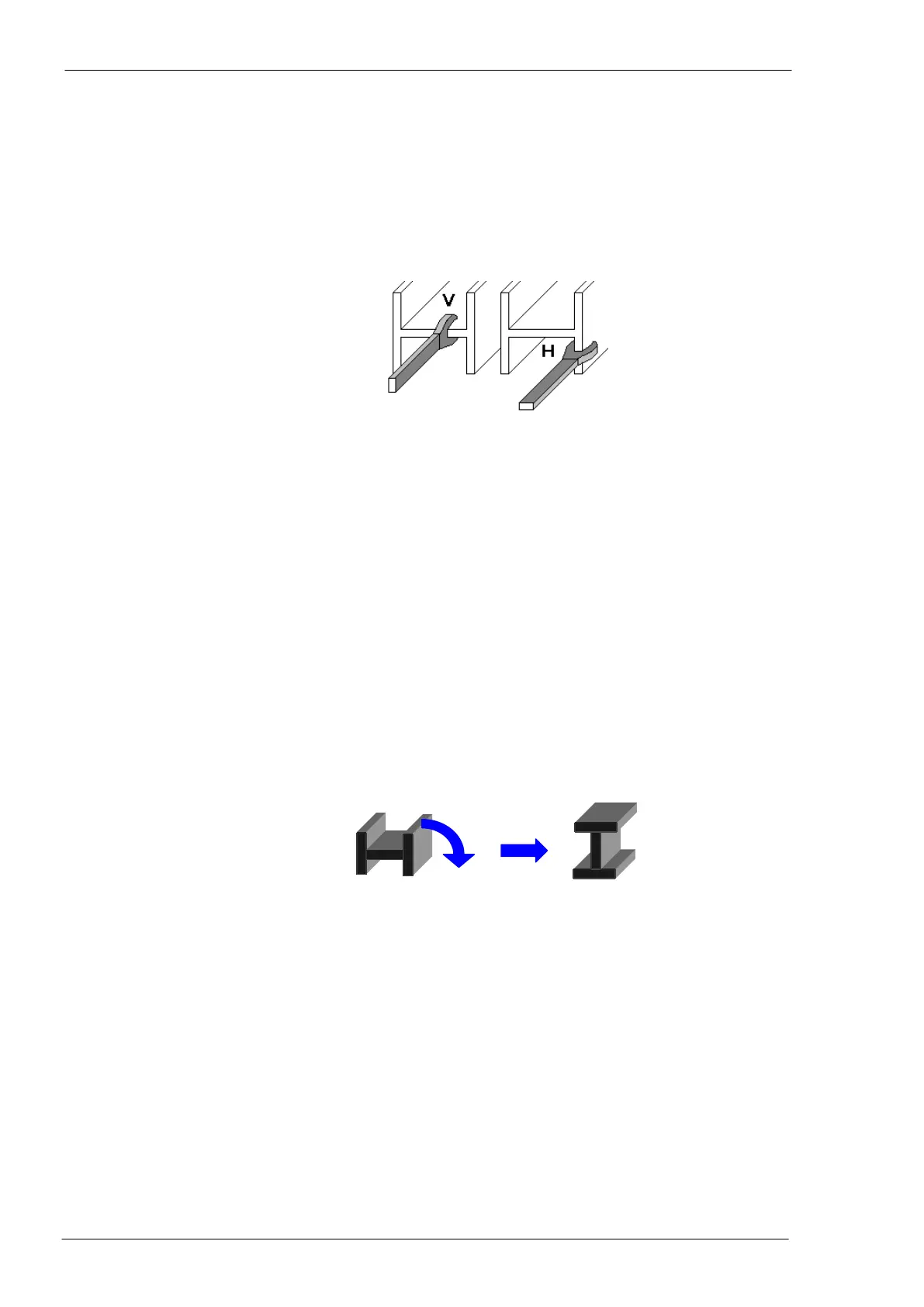

Pincher position; available options: vertical (the pincher takes material on the web)

or horizontal (the pincher takes material on the flange A); by this option the CNCC: is

allowed to position the pincher if the vertical movement of the pincher is a controlled

axis.

Position for material surplus; available options:

- surplus at the start of the profile

- surplus at the end of the profile (near the pincher)

Execution mode; available options:

- Passes: grouping by diameter: all holes (on all sides) with the same diameter are

executed, then the CNC changes tool and execute all holes with this second di-

ameter and so on. X axis moves in both directions and the number of tool changes

is the minimum possible. This mode is optimized to save time.

- Single pass: the profile can only move toward the cutting unit so for each hole, if

with different diameter from the previous one, the CNC must perform a tool

change. This mode is optimized to get maximum precision.

- Passes + under-passes: like passes but divided for each working side

- Single pass + under-passes: like single pass but divided for each working side

Checking this box the CNC automatically start the next job when the current is com-

pleted

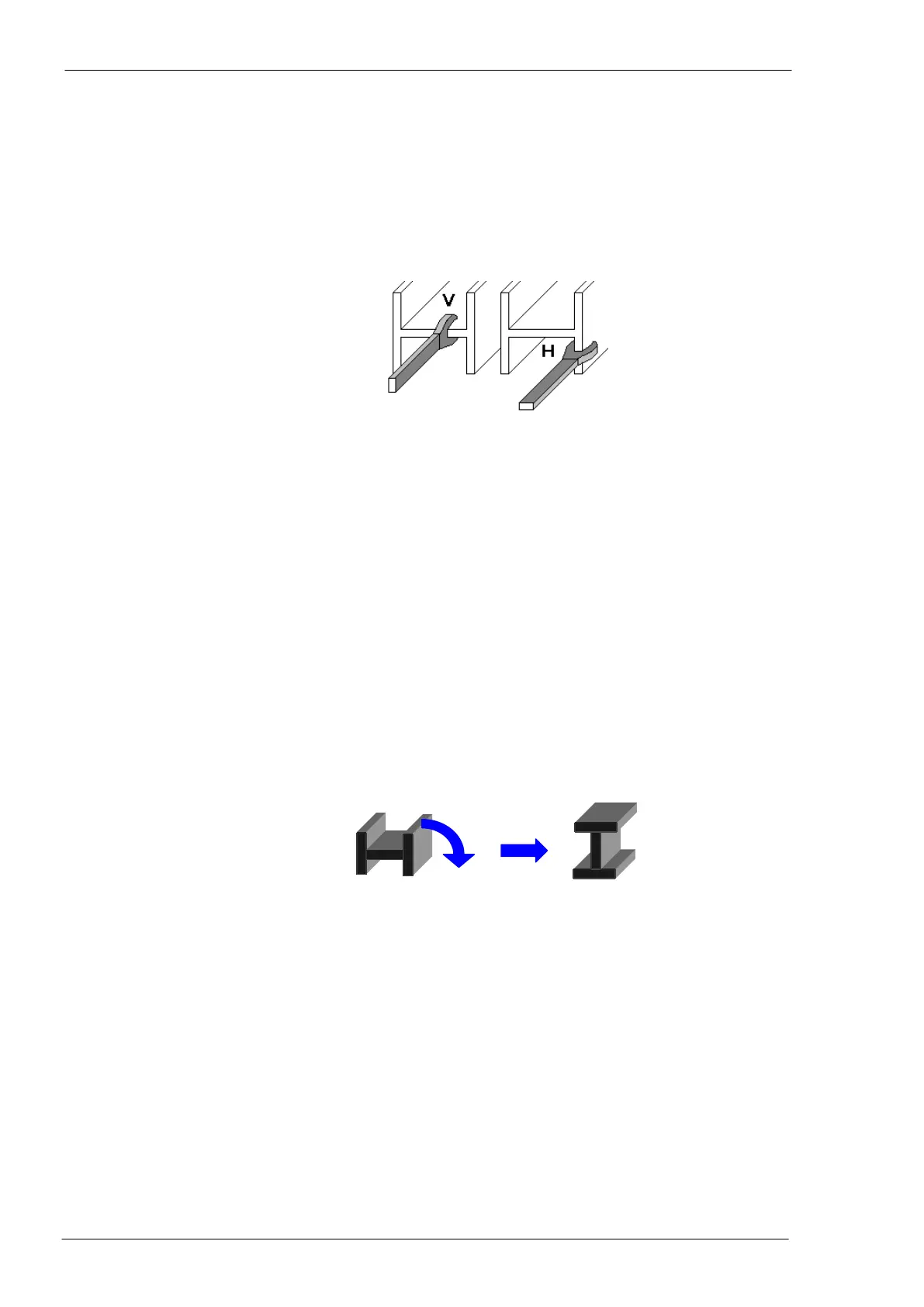

The job is to be executed in two different phases: drilling operations, automatic rota-

tion of the bar, cut of the pieces.

N.B. to enable this option the line must be equipped with a special optional device to

allow the automatic rotation of the bars.

This specification says to CNC that the profile is loaded rotated by 90° to perform

flanges cuts.

Allows the CNC to automatically perform tool turnover depending on the quantity of

material worked

Cooling limit for drilling tools; if this field is left empty the CNC takes the datum from

tool tables

Enable for initial and final angled cuts in cut-to-length piece circumscribed

Length threshold for the bar surplus in pincher zone:

- for surplus shorter than this value the machine unload the material

- for surplus longer than this value the CNC ask the operator to confirm the unload

operation; the operator can confirm pressing push-button “CONT” of auxiliary

push-button panel or reject by the push-button “RESET”; in this case the opera-

tor can use the surplus as a new bar)

Same logic of parameter n. 11 but evaluated in percentage of bar length; it could be

used to evaluate the quality of a nesting; if the total scrap is bigger than this value

the mark n. 29 in the nesting window becomes red.

N.B. 100% = control disabled

Initial cut to get well-squared initial edges of the profile (default 30 mm).

Material lost because of the saw blade thickness (default 2.2 mm)

Loading...

Loading...