Programming and operating manual Model 1001 DFB

84 FICEP S.p.A.

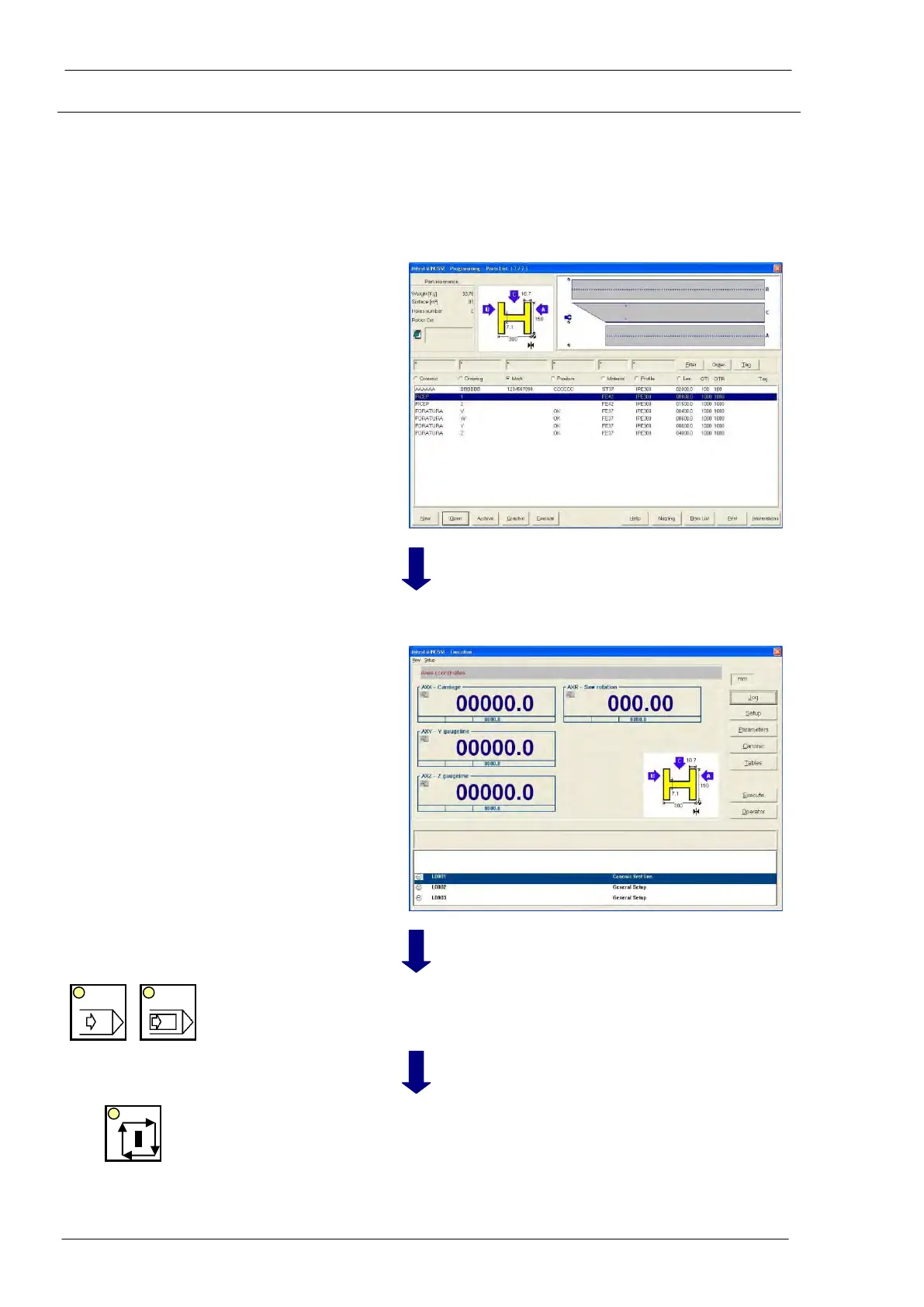

The “machine program”

(canonic program) is

generated

The operator can see for few seconds a service window

after which the previous window, with the pieces list is

shown again. It means that the canonic program has

been perfectly generated without errors.

If an error occurs (for instance, the program needs a tool

not present in the tool tables) an error message is dis-

played. The operator must remove the problem and, af-

ter, he must re-execute the program.

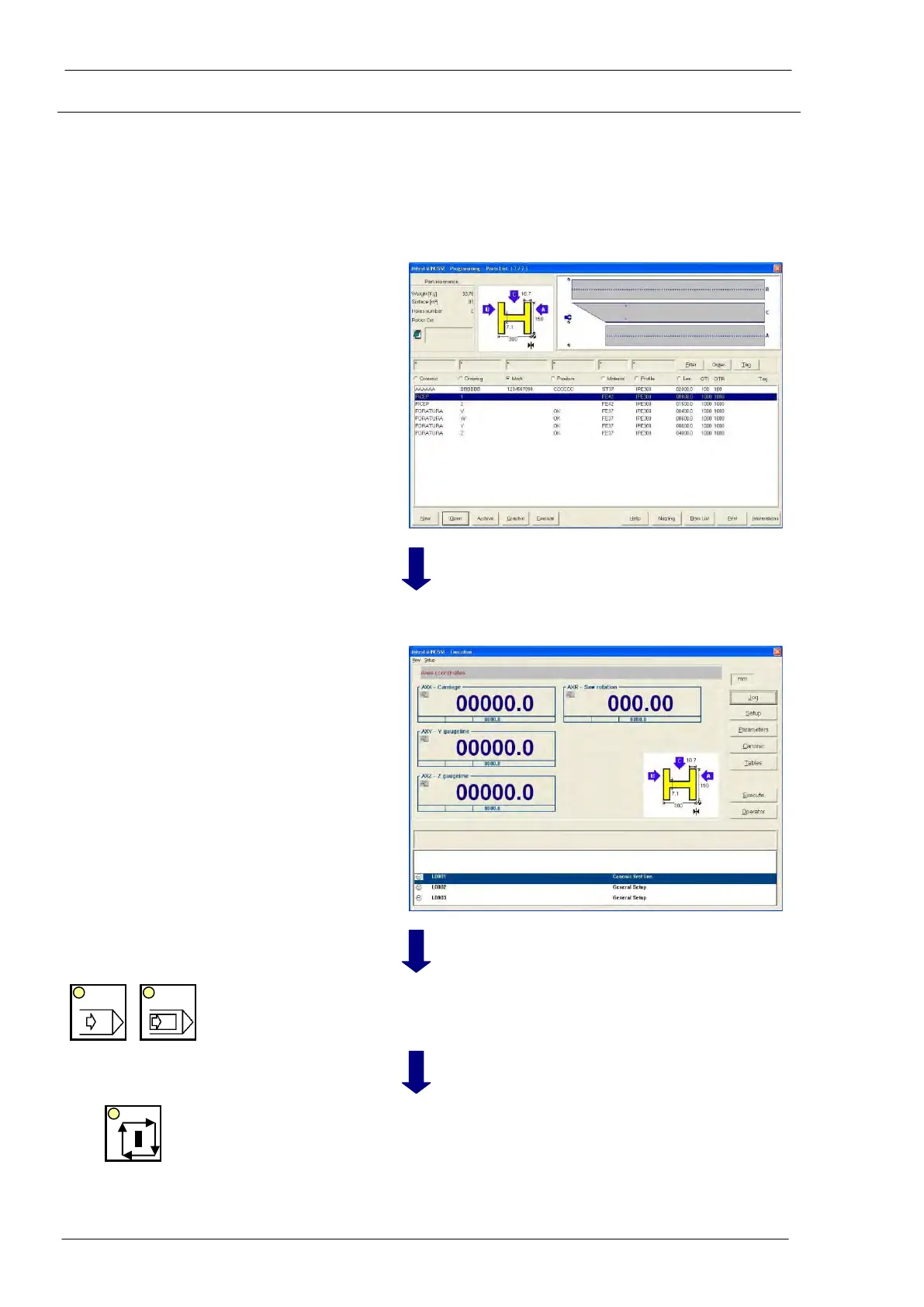

“ESC” of the PC

keyboard and,

then, graphic push-

button “Execution”

To supervise the execu-

tion of the program

The Execution window is displayed; the operator can

read dynamic information.

Selection of automatic

cycle

Choice of desired automatic cycle (continuous or step by

step)

The execution of the program is started. If the line setup

is suitable to the required setup, the pincher catches the

material, the LED into START push-button is ON and the

coordinates change dynamically; the line is working.

If the line setup is not the same as required, the CNC

stops the execution and automatically shows the setup

Loading...

Loading...